Integrated casing board type long piled wharf

A high-piled wharf and box-slab technology, applied in coastline protection, construction, jetty, etc., can solve the problems of heavy construction workload, poor integrity, short service life, etc., and achieve high overall rigidity of the structure, less amount of cast-in-place concrete, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

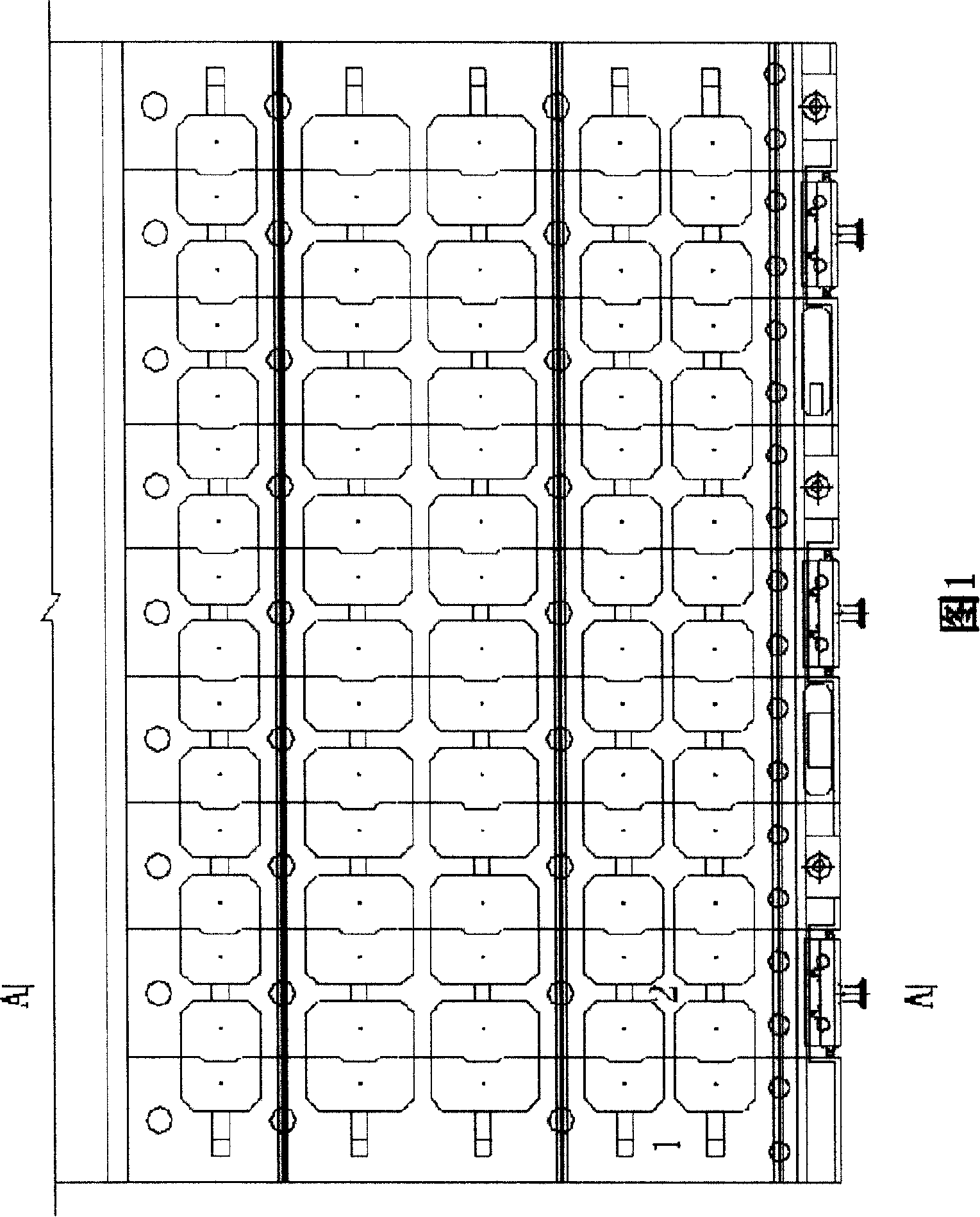

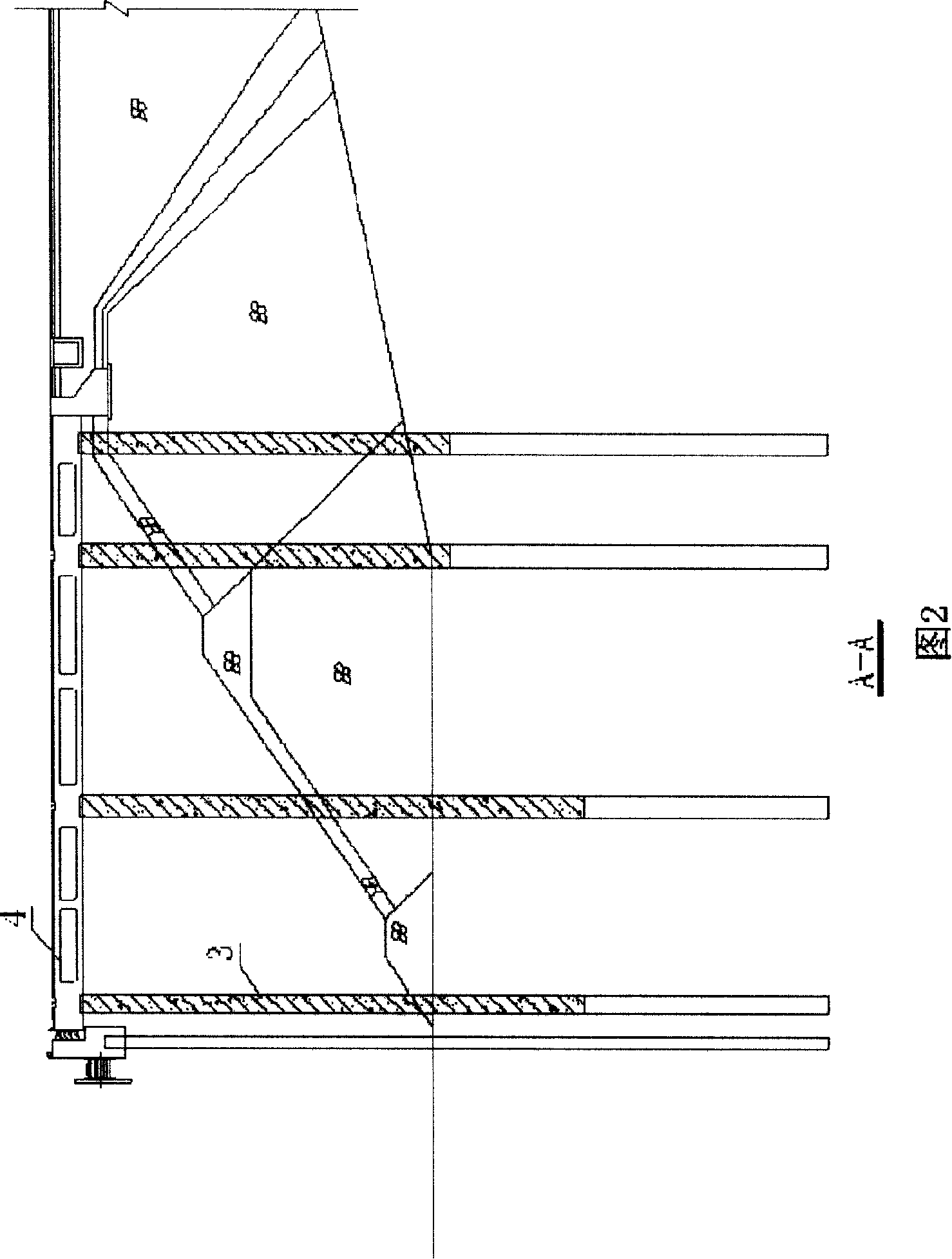

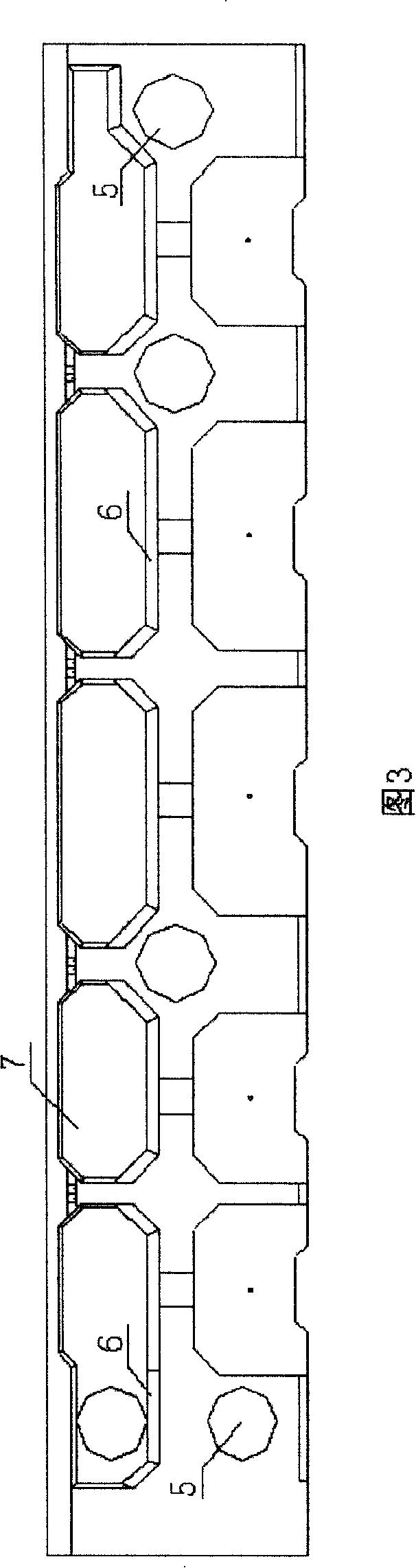

[0013] Below in conjunction with technical scheme and accompanying drawing, describe in detail the best embodiment of integral box plate type high-pile wharf structure:

[0014] The standard section of a pier is 54 meters long and 34.5 meters wide. Each box slab in the superstructure of the wharf has a width of 6 meters and a height of 1.5m, of which the thickness of the top and bottom slabs is 0.3 meters, the width of the transverse ribs of the box slabs is 0.8 meters, and the width of the longitudinal ribs on the piles is 2.6 meters and 2.2 meters. The rib width is 0.5m and 0.8m. A pier standard section consists of 9 prestressed box panels. The two-way prestressed box slab adopts a prefabricated unbonded prestressed structure along the transverse direction of the wharf, and adopts a post-tensioned bonded prestressed structure along the longitudinal direction of the wharf. The upper structure is connected into a whole through post-tensioned prestressed tendons along the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com