Self-insulating high-strength assembly blocks

A technology of thermal insulation blocks and blocks, which is applied in the field of building wall components and self-insulation high-strength assembly blocks, can solve the problems of easy cracking and falling off of the insulation layer, large construction volume, and difficult quality assurance, etc., so as to reduce the amount of cast-in-place concrete, Overcoming the large amount of formwork and reducing the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

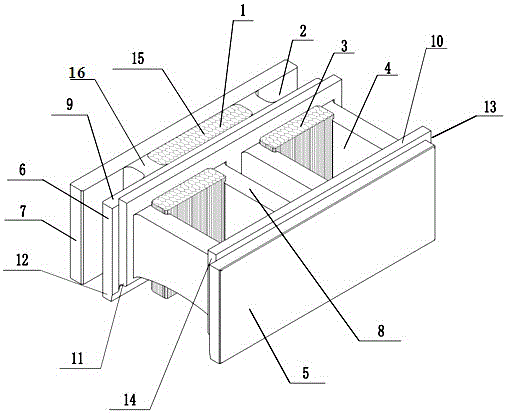

[0018] Such as figure 1 As shown, the self-insulating high-strength assembly block of the present invention is a solid component made of concrete material, wherein the solid component includes an outer plate 7, a middle plate 6 and an inner plate 5, and the outer The plate 7 is parallel to the middle plate 6, the middle plate 6 is parallel to the inner plate 5, two connecting blocks 16 are arranged between the outer plate 7 and the middle plate 6, and the front end of any one of the connecting blocks 16 and the rear ends are respectively connected with the outer plate 7 and the middle plate 6, a first heat insulation space 1 is arranged between the two connecting blocks 16, and a second heat insulating space 1 is respectively arranged on the outer sides of the two connecting blocks 16 2. There are four connecting ribs 8 between the middle plate 6 and the inner plate 5, the front end and the rear end of any one of the connecting ribs 8 are respectively connected with the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com