A clip-type splitting rod installation device

A technology for installing equipment and splitting rods, which is applied in the direction of earthwork drilling and discharge machinery, etc., can solve the problems of low operation efficiency, high labor cost, high risk, etc., and achieve high operation efficiency, low labor intensity, and The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described in conjunction with accompanying drawing and specific embodiment:

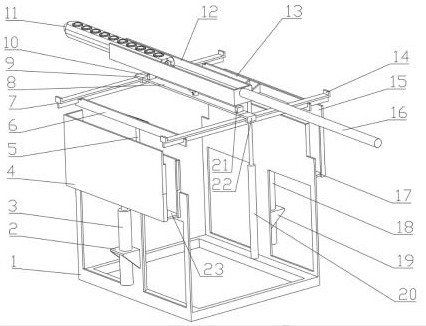

[0015] Such as Figure 1~2 As shown, a clip-type splitting rod installation device, the clip-type splitting rod installation device includes a splitting rod propulsion mechanism, an angle adjustment mechanism, a fine-tuning mechanism, and a splitting rod storage clip;

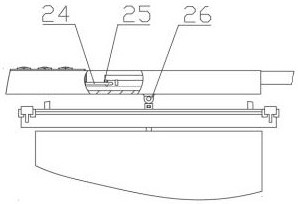

[0016] Described splitting rod propulsion mechanism is in order to use when described splitting rod 11 is advanced to face drilling; Described propulsion mechanism includes splitting rod chute 12, advances oil cylinder 16 and is used for splitting rod to advance The anti-off hook 25 that prevents falling off during the process; the splitting rod chute 1 is connected by the hinge 26 of the angle adjustment mechanism at its bottom to support and guide the splitting rod 11 that needs to be advanced; Described propulsion oil cylinder 16 is installed on the rear end face of described splitting rod c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com