Staggered steam turbine cylinder vertical connecting assembling surface assembly structure and steam turbine cylinder thereof

An assembly structure and steam turbine technology, which is applied in the field of steam turbine cylinders, can solve the problems of loss of working fluid, large impact, secondary accidents, etc., and achieve the effect of reducing the risk of steam leakage, reducing the risk of steam leakage, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

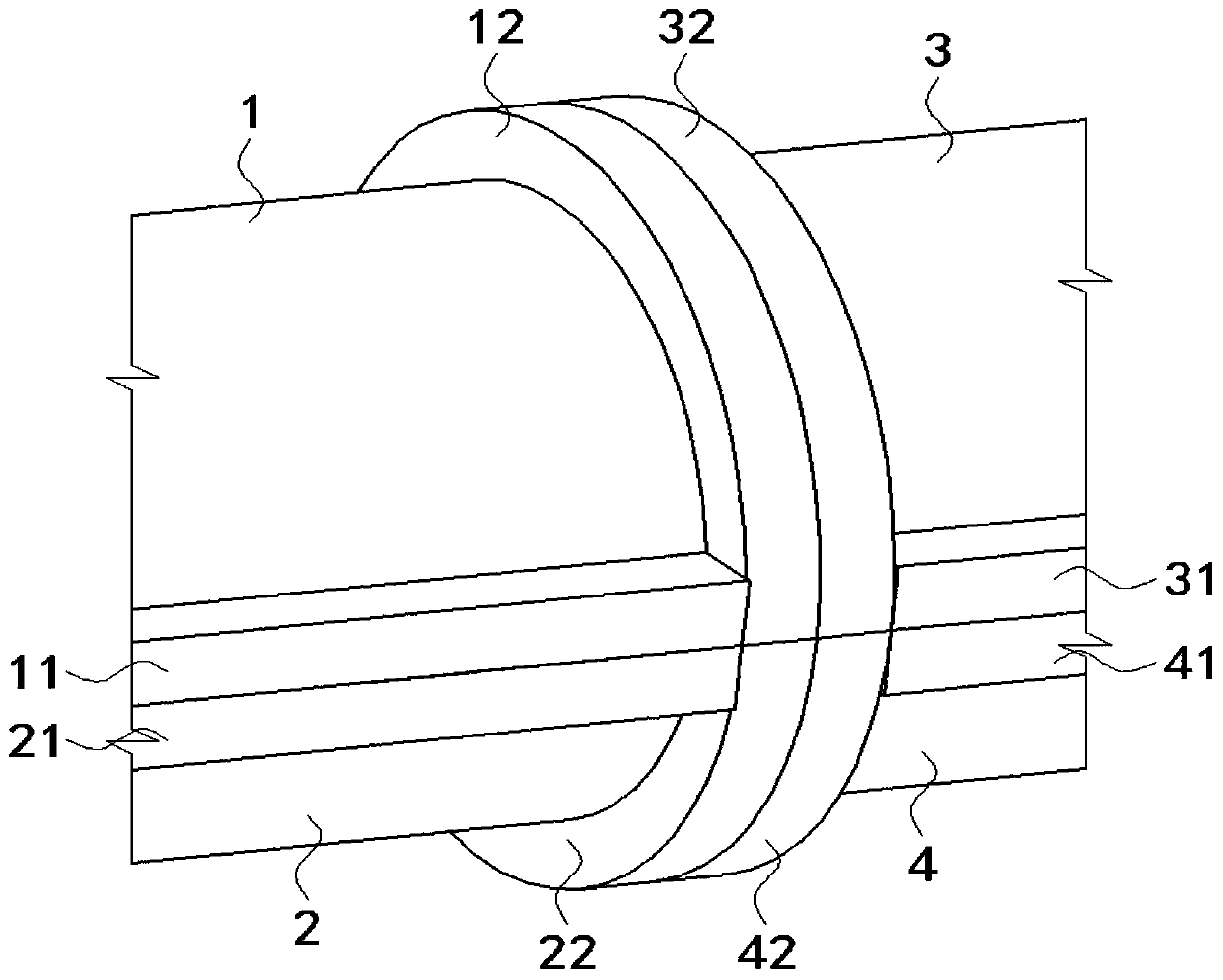

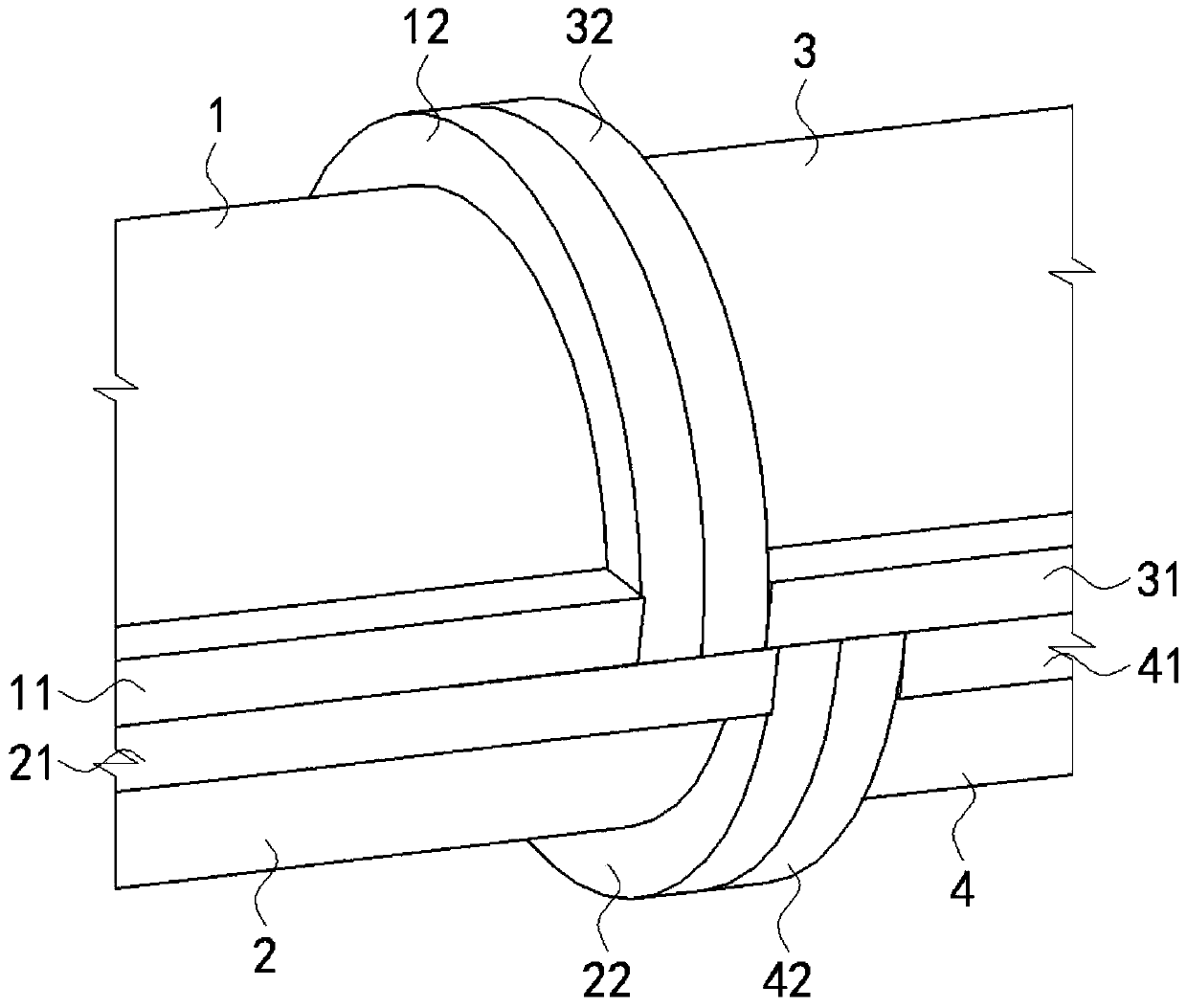

[0040] Such as Figure 3 to Figure 5As shown, a staggered steam turbine cylinder vertical joint surface assembly structure of Embodiment 1 includes a connected steam turbine front cylinder and a steam turbine rear cylinder; the steam turbine front cylinder is composed of the upper half 1 of the steam turbine front cylinder and the lower half 2 of the steam turbine front cylinder, The steam turbine rear cylinder is composed of the upper half 3 of the steam turbine rear cylinder and the lower half 4 of the steam turbine rear cylinder; Horizontally connected to the mating surface 5; between the upper half 1 of the front cylinder of the steam turbine and the upper half 3 of the rear cylinder of the steam turbine, the upper half of the cylinder cylinder is vertically connected to the mating surface 6; between the lower half 2 of the front cylinder of the steam turbine and the lower half 4 of the rear cylinder of the steam turbine to form a cylinder cylinder The lower half of the ve...

Embodiment 2

[0058] A steam turbine cylinder in Embodiment 2. The steam turbine cylinder includes multi-stage cylinders. A staggered steam turbine cylinder vertical mating surface assembly structure in Embodiment 1 is adopted, so that each stage of cylinder is assembled to form the steam turbine cylinder.

[0059] Further, the steam turbine cylinder includes a 2-stage cylinder, or, the steam turbine cylinder includes a 3-stage cylinder.

[0060] In one embodiment, the cylinder of the steam turbine includes two sections of cylinders. As mentioned in the background art, a certain type of pure condensing steam turbine consists of two sections of cylinders in the axial direction, which are respectively the front cylinder and exhaust cylinder of the steam turbine. The front cylinder of the steam turbine corresponds to the front cylinder of the steam turbine in the first embodiment, and the exhaust cylinder of the steam turbine corresponds to the rear cylinder of the steam turbine in the first em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com