Expert control system and control method based on batch coating machine

A technology of expert control and expert system, which is applied in the field of seed coating, can solve problems such as inability to coordinate and orderly work of various components, difficulty in achieving precise control, and low degree of intelligence, so as to save the amount of coating agent, improve efficiency, and improve the effect. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The content of the invention of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

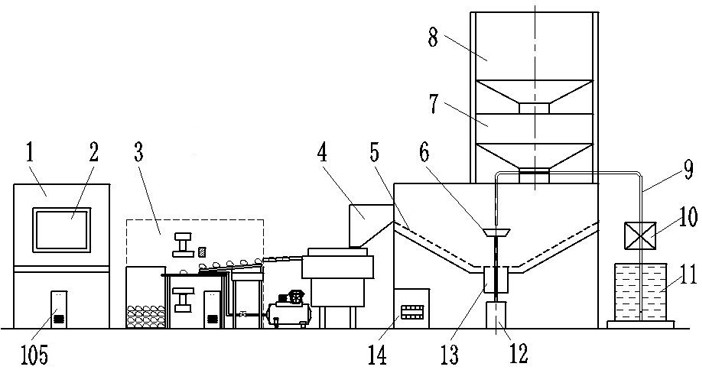

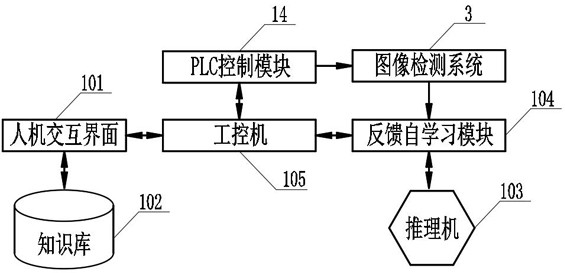

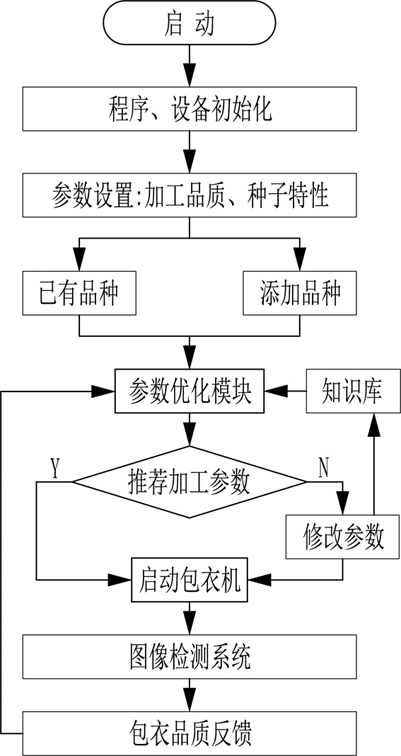

[0033] see Figure 1-2A kind of expert control system based on batch type coating machine shown, comprises coating machine and image detection system 3, and described coating machine is batch type coating machine, consists of dosing system, feeding system, coating System and PLC control module 14 are formed, and described PLC control module 14 is respectively connected with dosing system, feeding system and coating system signal, is used for controlling the operation of coating machine; Described PLC control module 14 is mainly composed of PLC components and devices and Compositions such as touch screen, preferably, the PLC control module that selects in the present embodiment is Siemens S7-200 type, so control the working conditions in the coating machine by PLC control module, and carry out data acquisition and monitori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com