Embedded random texture anti-counterfeiting mark structure and manufacturing method

An anti-counterfeiting label and manufacturing method technology, applied in the field of anti-counterfeiting, can solve the problems of loss of anti-counterfeiting effect, easy wear and tear of random textures, recycling and reuse of illegal elements, etc., and achieves the effect of saving installation space, preventing fraudulent behavior, and saving opening space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

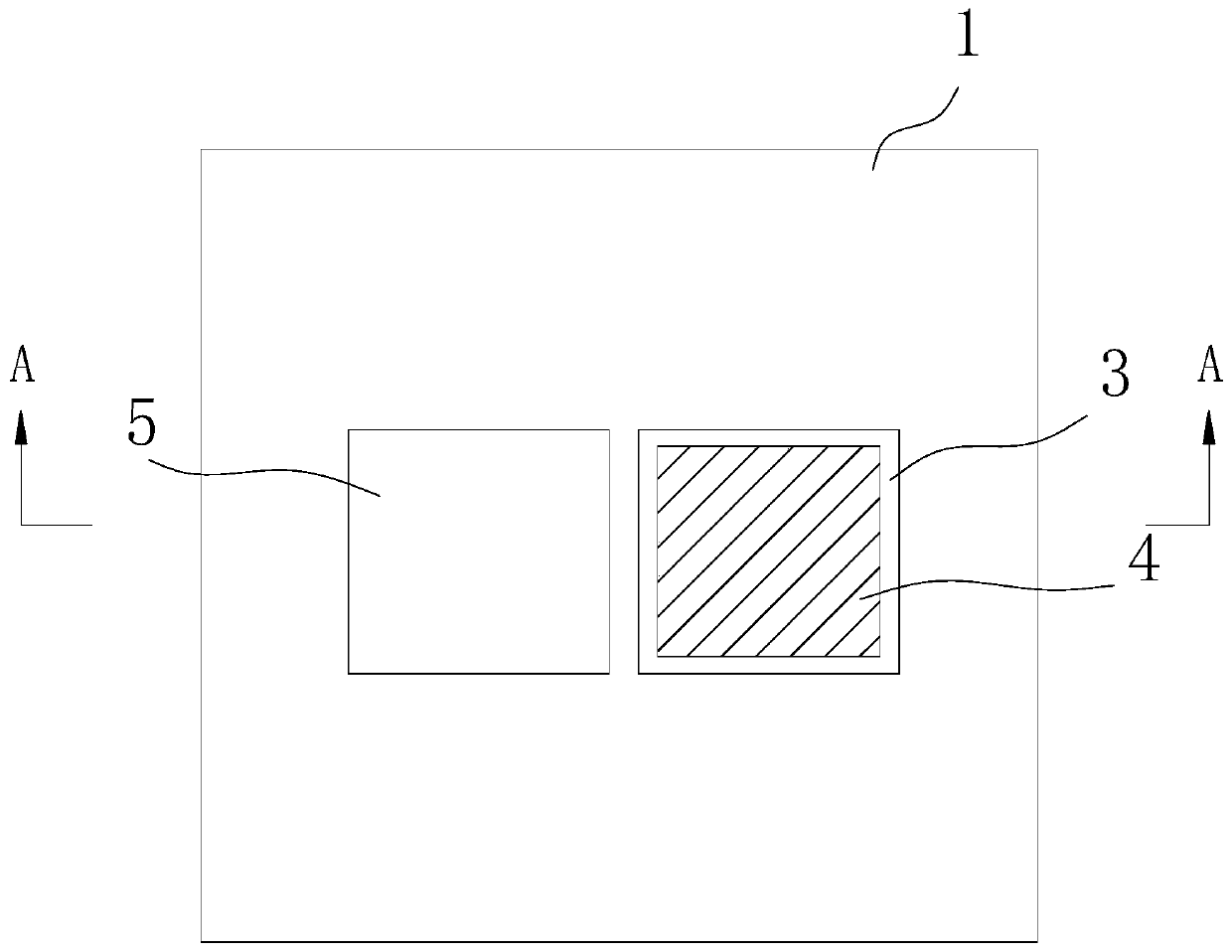

[0046] Please refer to figure 1 and figure 2 ,in figure 1 It is a structural schematic diagram of the first embodiment of the anti-counterfeiting label structure of the present invention, figure 2 for figure 1 As shown in the figure, the embedded random texture anti-counterfeiting label structure of the present invention mainly includes: a substrate 1, on which a slot hole is opened; a bottom layer 2, fixed under the substrate 1, covering the slot hole , the groove part on the substrate 1 and the bottom layer 2 form a groove 3; the random texture layer 4 is arranged on the bottom layer 2 and is located inside the groove 3.

[0047] The material of the substrate 1 is not limited, for example, it can be a common cardboard, and the substrate 1 is provided with a slot, and the slot can be formed by conventional punching equipment. Substrate 1 can be a separate component and be arranged on the product packaging or product body that needs anti-counterfeiting, and can also be a...

no. 2 example

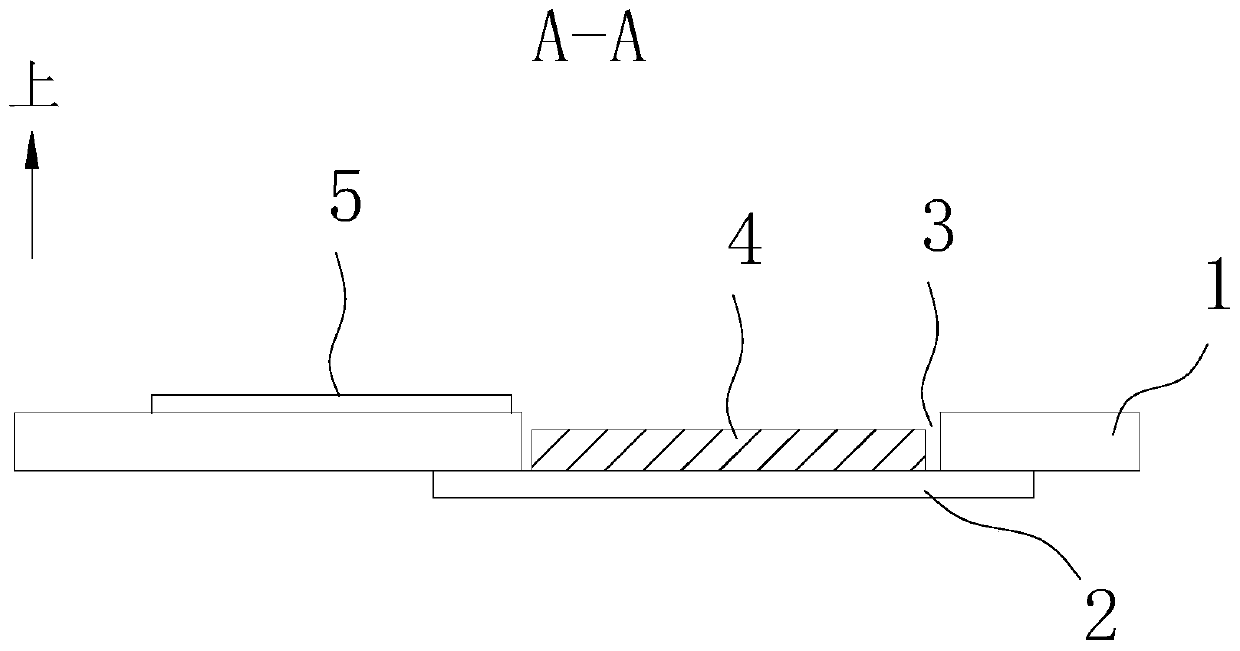

[0052] Please refer to image 3 , is a structural schematic diagram of the second embodiment of the anti-counterfeiting label structure of the present invention. As shown in the figure, the difference between this embodiment and the above-mentioned first embodiment is that the coding layer 5 and the random texture layer 4 in this embodiment are arranged on the bottom layer together 2, located inside the groove 3. In this way, the coding layer 5 can also be protected by the grooves to avoid abrasion. The coding layer 5 remains adjacent to the random texture layer 4, so that the simultaneous shooting of the coding layer pattern and the random texture layer pattern can be easily realized no matter when the reference data is collected or entered or when the consumer takes pictures of the anti-counterfeiting marks on the product.

[0053] Other structures and features in this embodiment are the same as those of the first embodiment above, and have the same technical effects, and w...

no. 3 example

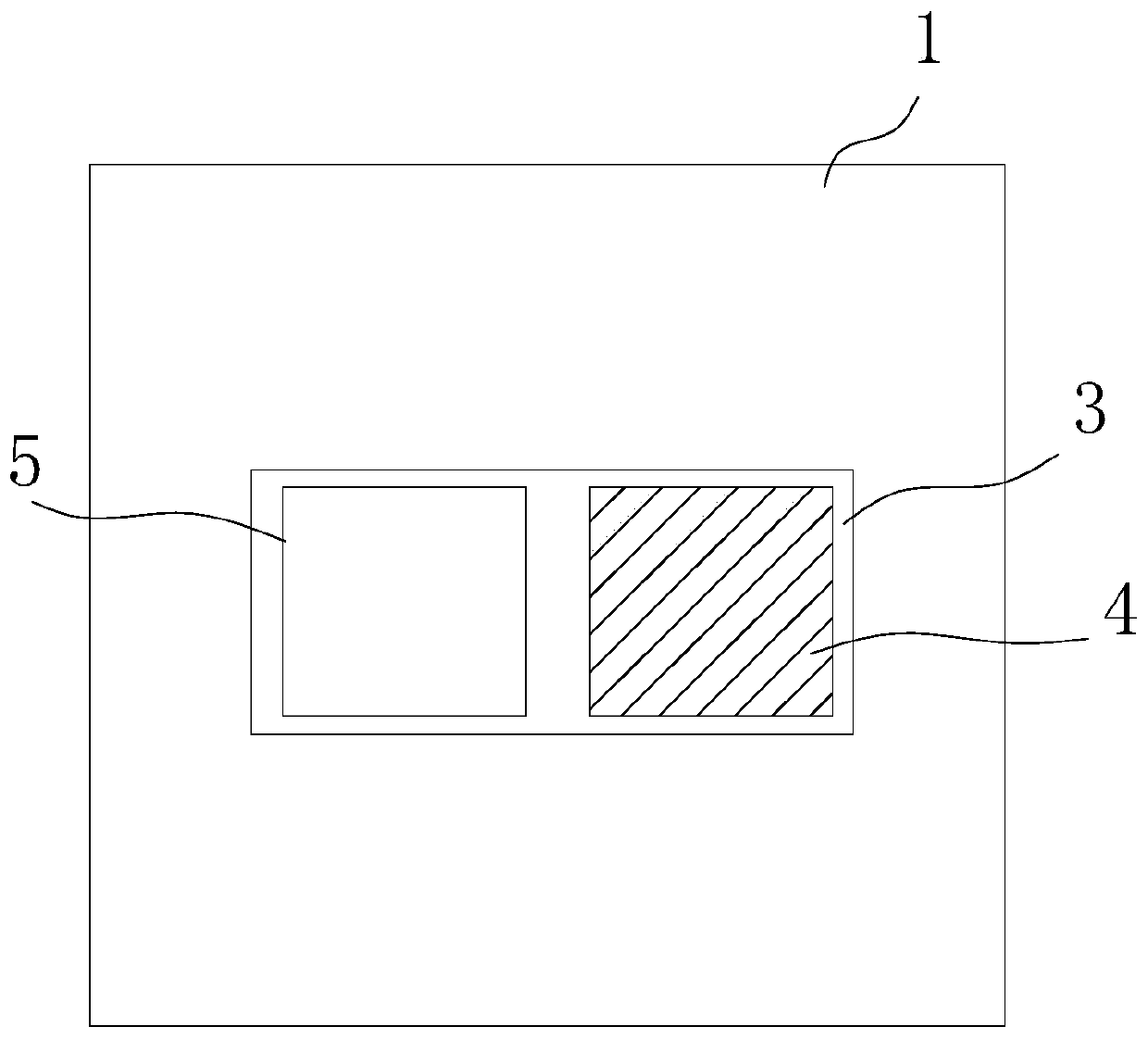

[0055] Please refer to Figure 4 , is a structural schematic diagram of the third embodiment of the anti-counterfeiting label structure of the present invention, as shown in the figure, the difference between this embodiment and the above-mentioned first embodiment is that the coding layer 5 in this embodiment includes a first coding part 51 and a second coding part 51 Part 52, wherein the first coding part 51 is arranged in the groove 3 together with the random texture layer 4, and the second coding part 52 is arranged on the substrate 1, which is the same as the random texture layer 4 and the first coding part 51 in the groove 3. adjacent.

[0056] The solution of this embodiment, on the one hand, can save the opening space of the groove 3, and is suitable for the situation where the product packaging space is limited and the size of the anti-counterfeiting label is relatively small. On the other hand, in the process of photographing and recording the reference pattern data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com