Self-circulating evaporating cooling distribution transformer

A distribution transformer and evaporative cooling technology, applied in the field of transformers, can solve the problems of transformer insulation damage, reduce the efficiency of ground rod replacement, increase the labor intensity of staff, etc., to ensure normal operation, reduce manual operation intensity, and enhance sound absorption efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

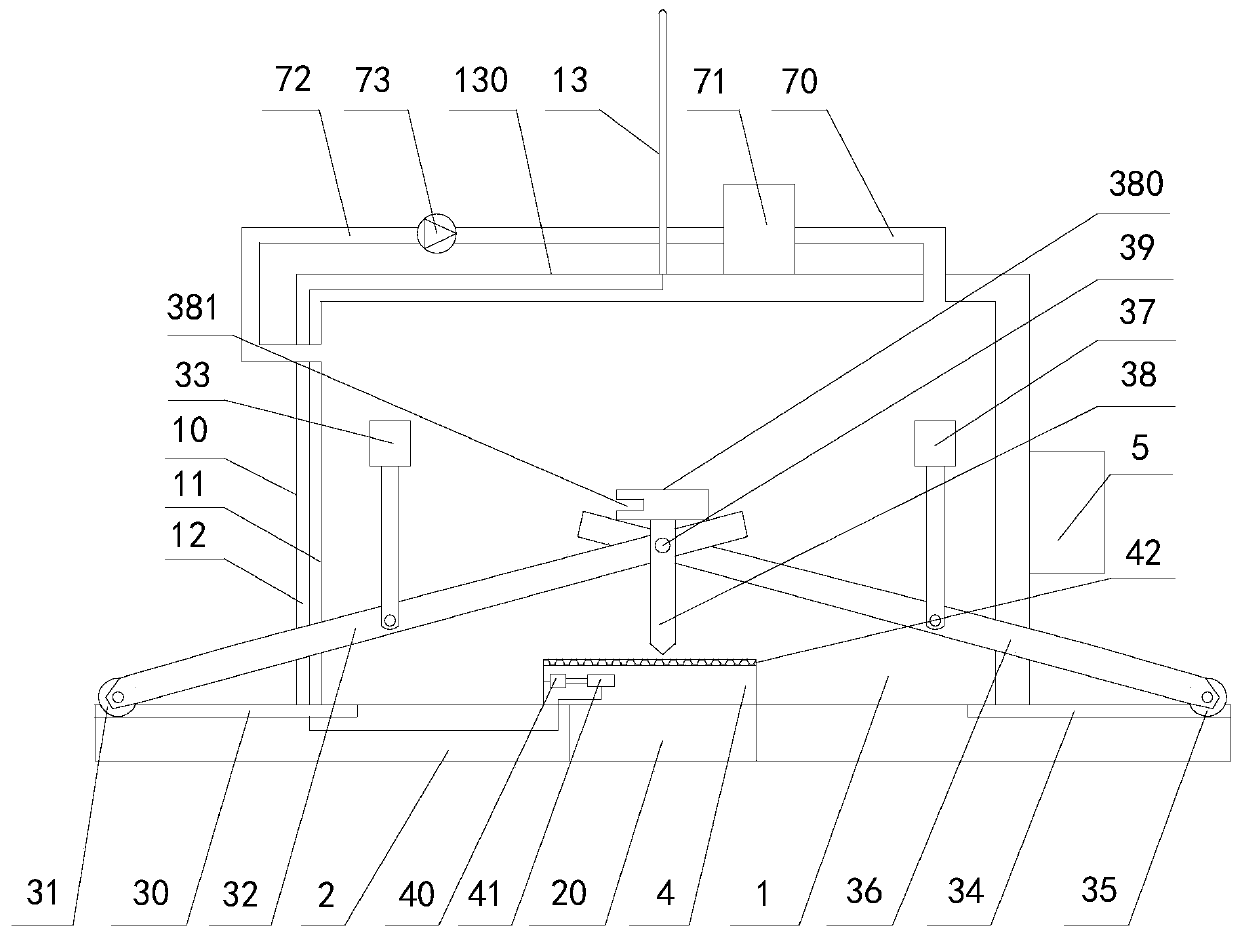

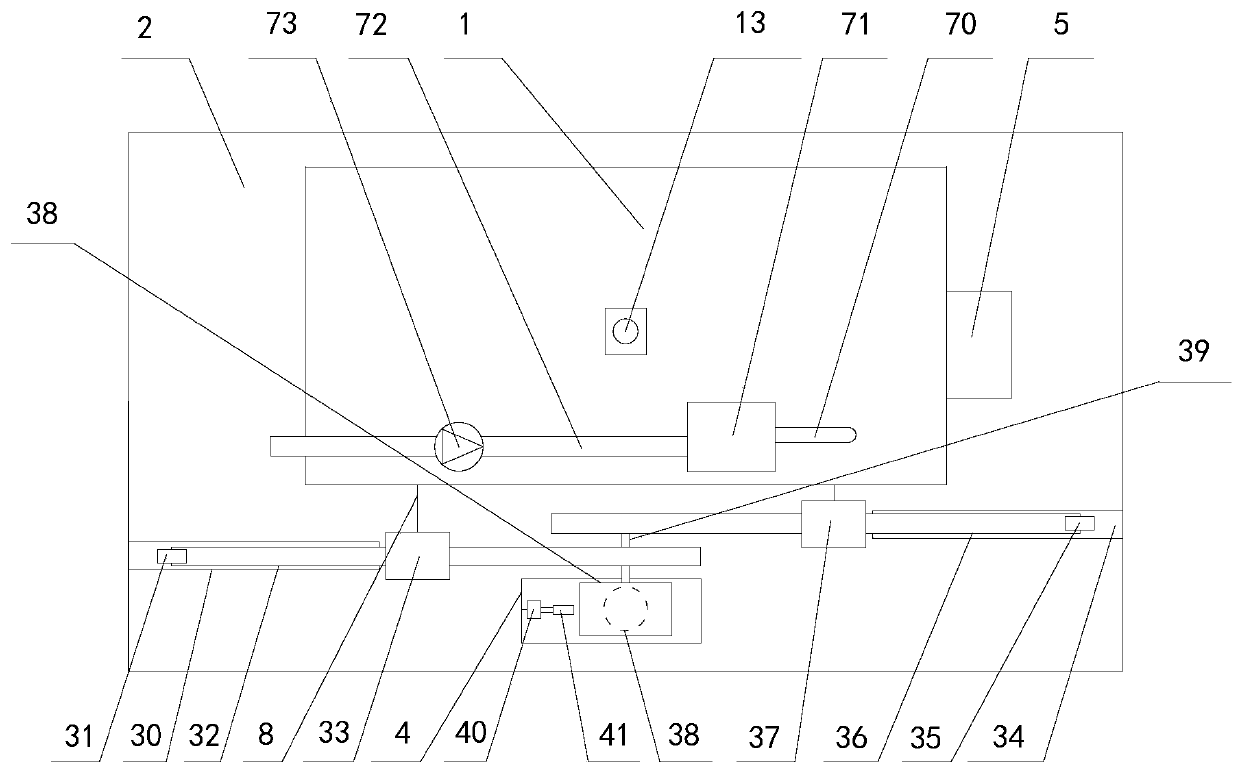

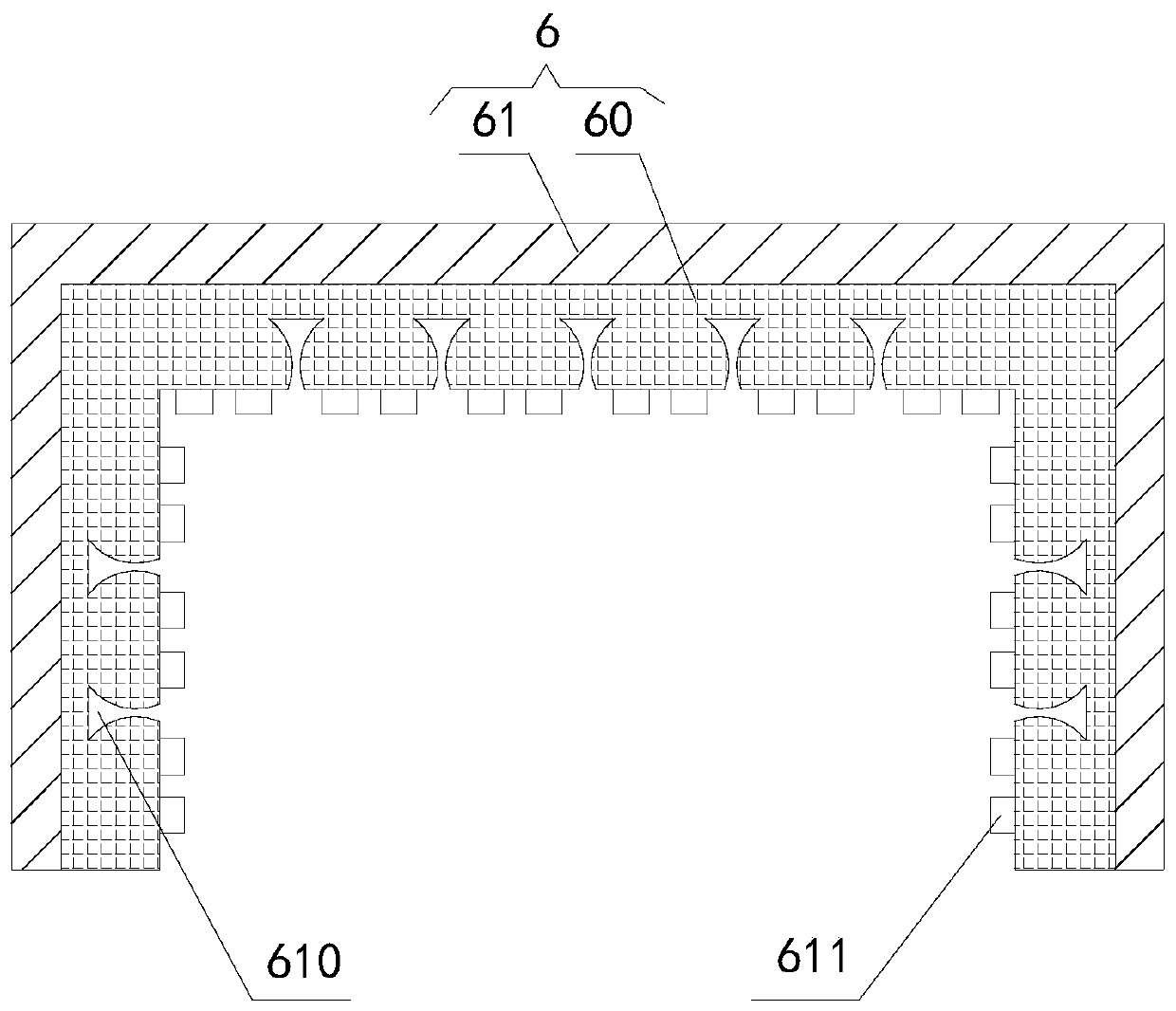

[0031] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0032] Such as Figure 1-3As shown, one embodiment of the present invention discloses a self-circulating evaporative cooling distribution transformer, including a transformer body 1, a base 2 located below the transformer body 1, and a ground rod lifting device. The transformer body 1 is fixed on the base 2, and the transformer body 1 is fixed on the base 2. The body 1 includes an outer shell 10 and an inner shell 11, and a sound-absorbing interlayer 12 is arranged between the outer shell 10 and the inner shell 11; a lightning rod 13 is arranged on the top of the transformer body 1, and the bottom of the lightning rod 13 is electrically connected to one end of a wire 130; the ground rod The lifting device is located directly in front of the transformer body 1. The grounding ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com