Display substrate, preparation method thereof and display device

A technology for displaying substrates and bases, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc. bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

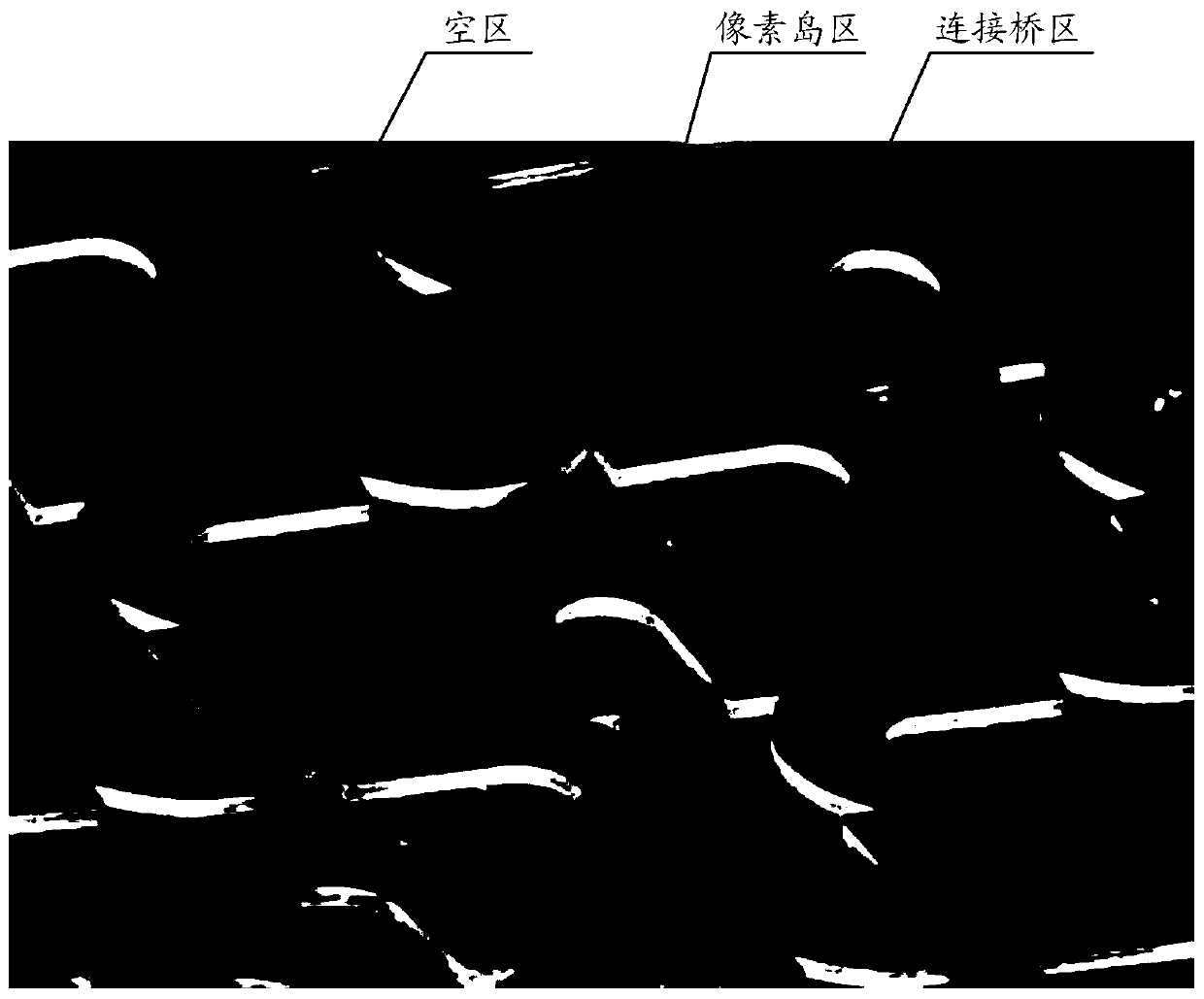

[0062] In order to solve the above technical problems, an embodiment of the present invention proposes a method for preparing a display substrate. The display substrate includes a plurality of pixel island regions, empty regions arranged between adjacent pixel island regions, and connecting bridge regions connecting adjacent pixel island regions. The preparation method of the display substrate includes:

[0063] Provide a hard substrate;

[0064] A first groove and a second groove are formed on one side of the substrate, the first groove corresponds to the pixel island region, and the second groove corresponds to the connection bridge region;

[0065] The display substrate is prepared on the side of the substrate where the first groove and the second groove are formed, the pixel island area is located in the first groove area, and the connection bridge area is located in In the second groove area, the empty area is located in an area outside the first groove and the second gr...

no. 1 example

[0070] The first embodiment of the present invention provides a method for preparing a display substrate. The display substrate includes a plurality of pixel island regions, empty regions arranged between adjacent pixel island regions, and connecting bridge regions connecting adjacent pixel island regions. The island area is provided with a light-emitting unit, and the connecting lines between adjacent pixel islands are arranged in the connecting bridge area.

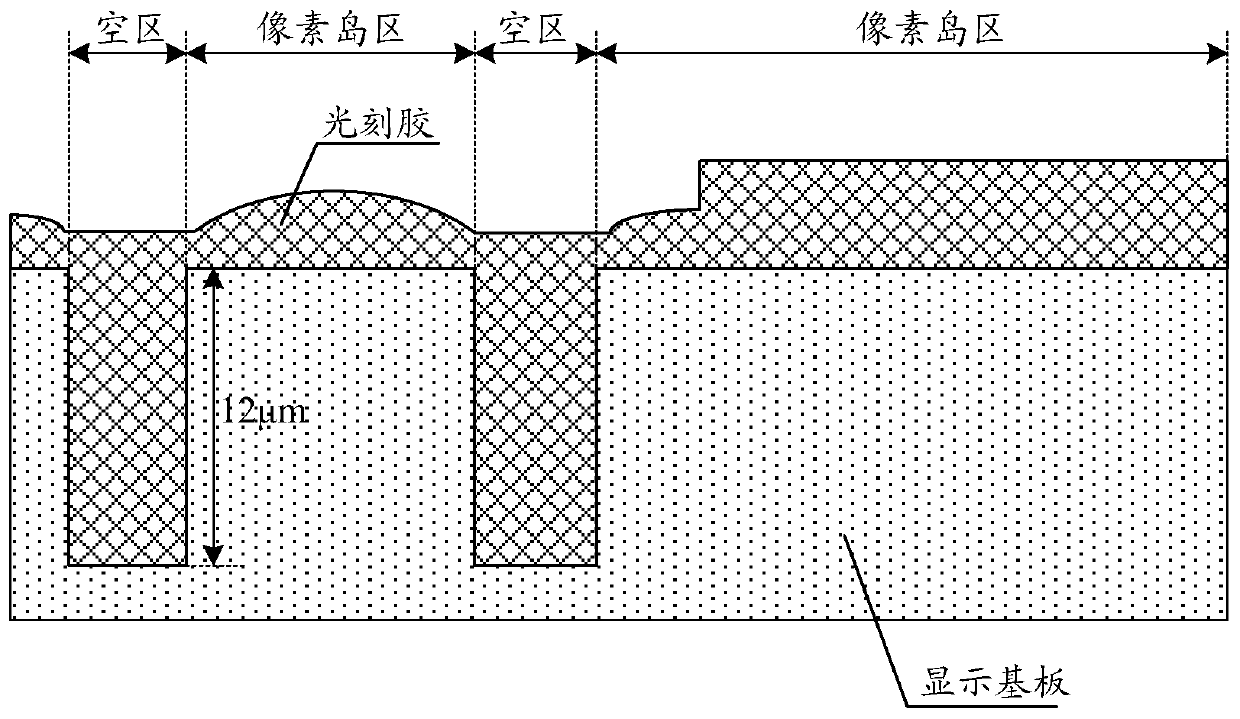

[0071] Figure 4 It is a schematic diagram showing the preparation method of the substrate according to the first embodiment of the present invention, such as Figure 4 As shown, the preparation method of the display substrate includes:

[0072] Provide a hard substrate;

[0073] A first groove 11 and a second groove 12 are formed on one side of the substrate, the first groove 11 corresponds to the pixel island region, the second groove 12 corresponds to the connection bridge region, and the first groove 11 and the se...

no. 2 example

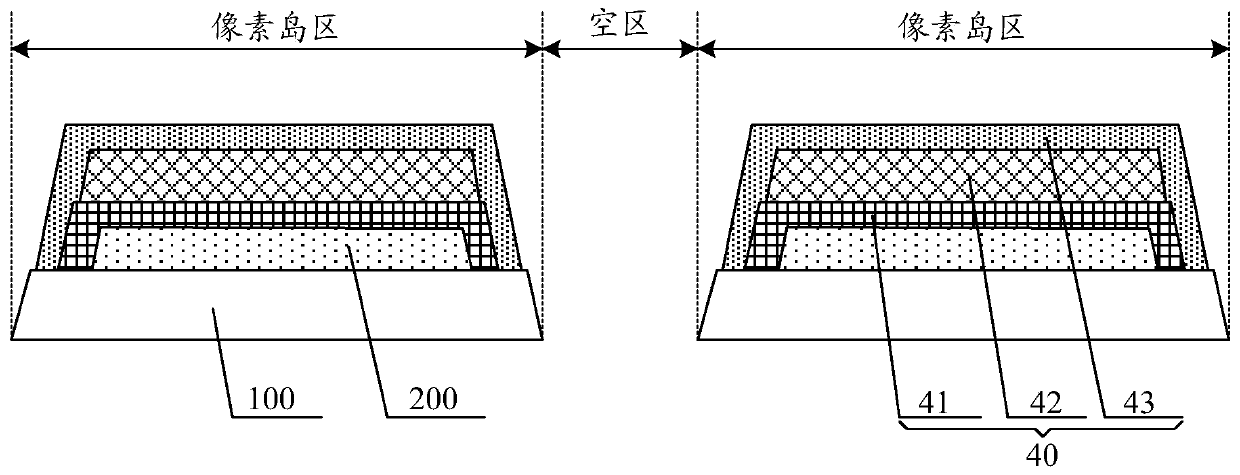

[0109] The second embodiment of the present invention provides a method for manufacturing a display substrate. Figure 8 It is a schematic diagram of the structure after forming the first groove and the second groove on one side of the substrate according to the second embodiment of the present invention. Different from the first embodiment, in this embodiment, the depth of the first groove 11 is w1, and the depth of the second groove 12 is w2. In this embodiment, w1<w2.

[0110] Figure 9 It is a schematic diagram of the structure after the base is formed on the substrate in the second embodiment of the present invention. In this embodiment, the base 20 is a flexible base, and the base 20 has a first thickness m1 corresponding to the first groove 11 , a second thickness m2 corresponding to the second groove 12 , and the first groove 11 and the second groove The area outside the groove 12 corresponds to the third thickness m3. Since w1m1>m3. In one embodiment, the first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com