Sandwiched honeycomb structure of radome

A honeycomb structure and radome technology, which is applied to the radiation unit cover, antennas and instruments suitable for movable objects, etc., can solve the problems of honeycomb destruction of carrying capacity, reduction of honeycomb accumulation, and reduced electrical performance of honeycombs, so as to enhance the bearing capacity. Ability, good wave transmission performance, small weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

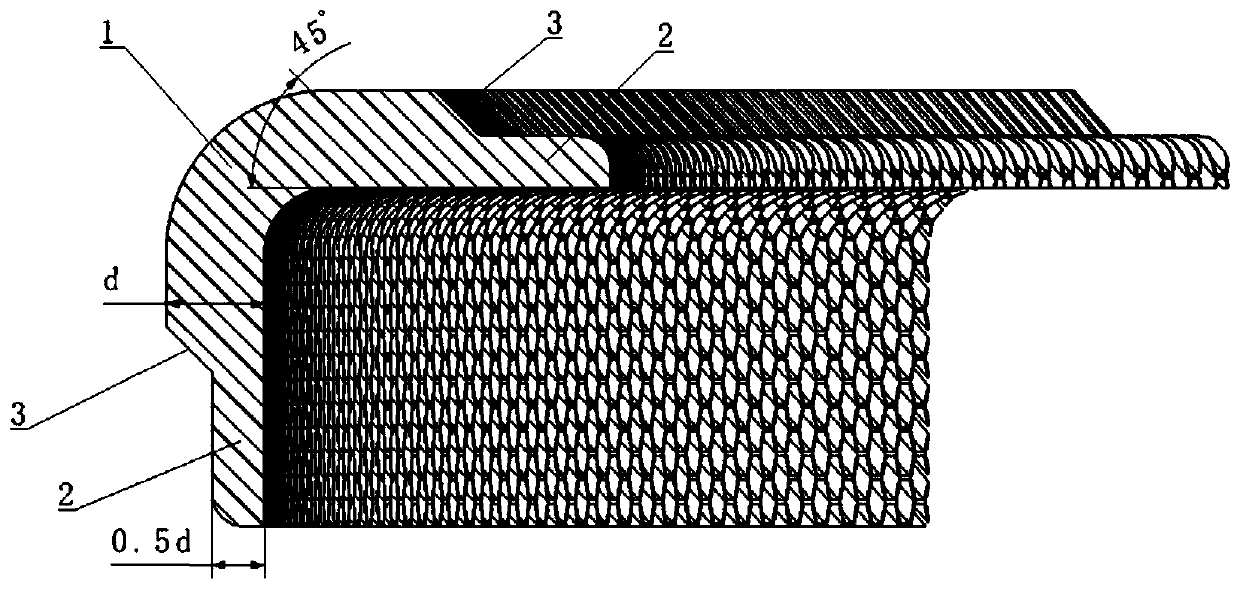

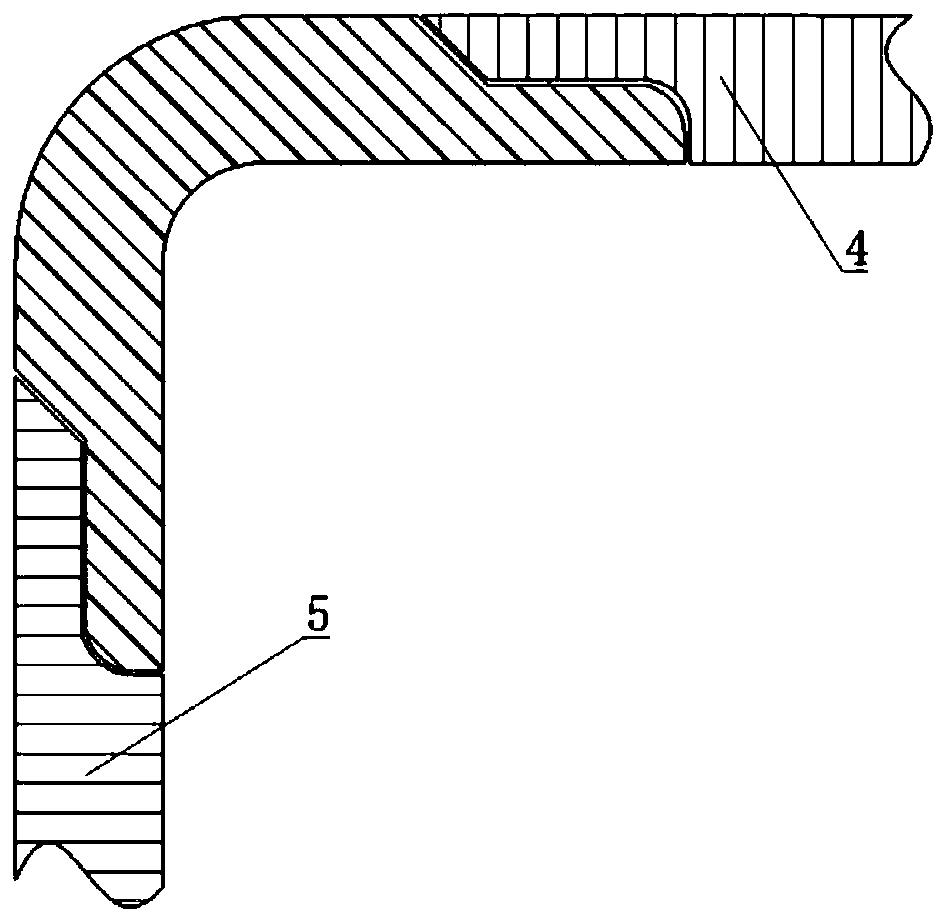

[0014] In order to realize the electrical performance and carrying capacity of the right-angle radome area to meet the requirements of use, a radome sandwich honeycomb structure is proposed. The structure is as figure 1 As shown, it includes design thickness area 1, overlapping area 2, and slope transition area 3. During the production process of the radome, the transitional honeycomb is spliced with the planar honeycomb 4 and the facade honeycomb 3, and adhesive film is used at the splicing seam solidified. The edges of the planar honeycomb 4 and the facade honeycomb 5 are processed to conform to the shape of the overlapping area 2 and the slope transition area 3 .

[0015] On the basis of the above-mentioned honeycomb structure, the angle between the cell direction of the transitional honeycomb structure and the plane of the radome is 30-60°, preferably 45°, and the honeycomb thickness in the design thickness area is the honeycomb thickness of the radome designed for elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap