Ink application apparatus and method for applying ink

A coating device, ink technology, applied in chemical/electrolytic methods to remove conductive materials, printed circuit coatings, patterns and photolithography, etc., can solve problems such as difficult to speed up scanning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

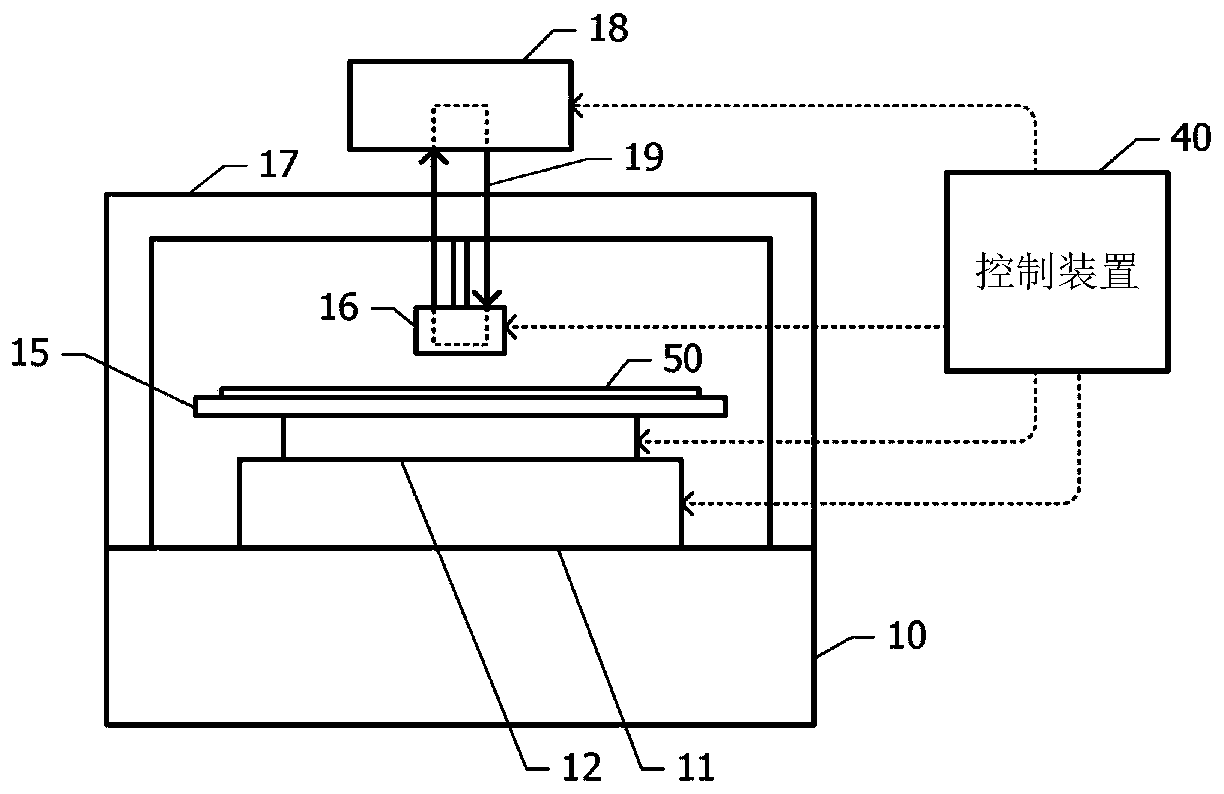

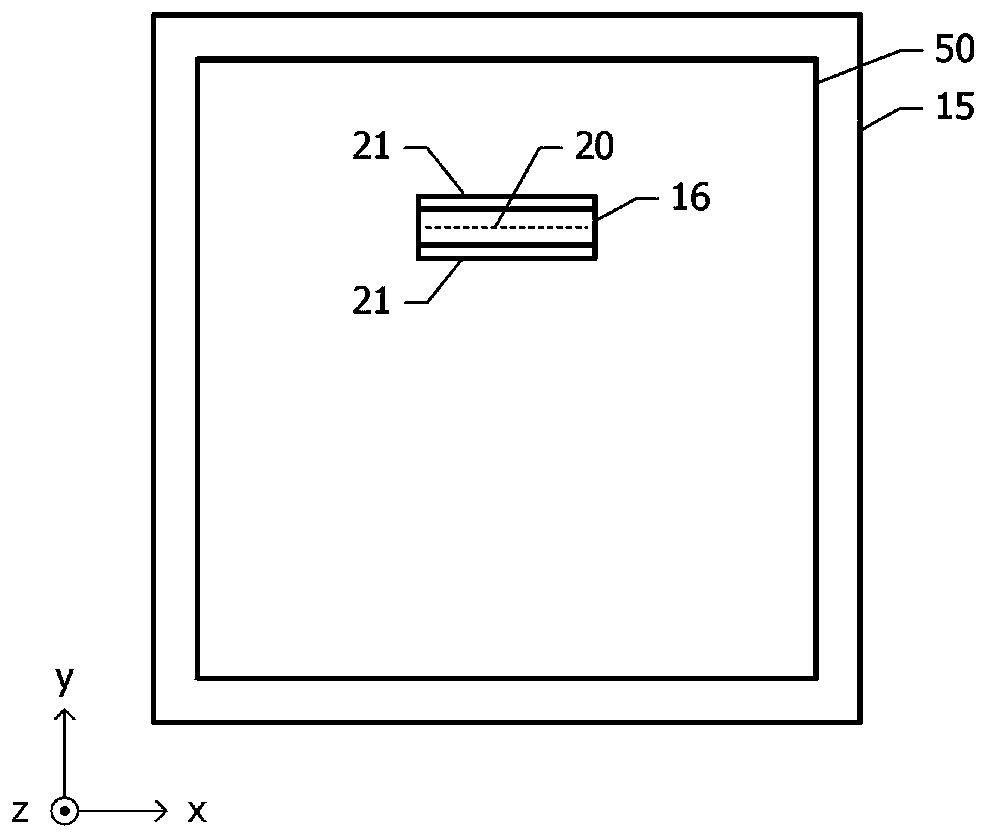

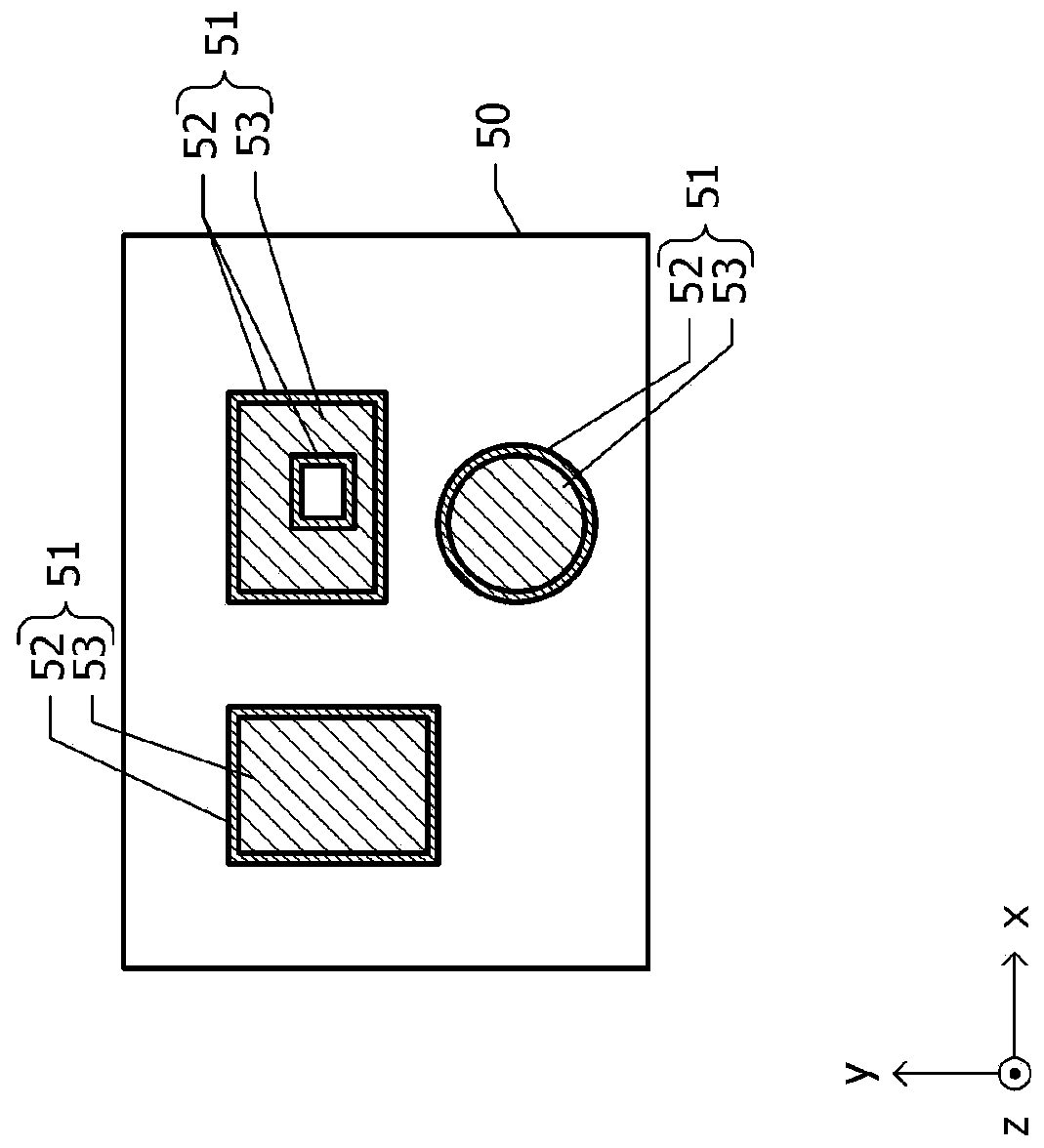

[0042] Below, refer to Figure 1A ~ Figure 3 , the ink application device based on the embodiment will be described.

[0043] Figure 1A It is a schematic diagram of the ink application apparatus based on an Example. On the stage 10 , a table 15 is supported via the XY stage 11 and the θ stage 12 . The object to be coated 50 is supported on the support surface of the table 15 . The object to be coated 50 is, for example, a substrate such as a printed circuit board. For example, the table 15 includes a vacuum chuck mechanism, and the object to be coated 50 is vacuum-adsorbed and fixed on the supporting surface. The supporting surface is, for example, parallel to the horizontal plane and faces upward in the vertical direction.

[0044]The XY stage 11 translates the table 15 relative to the stage 10 in two directions parallel to the supporting surface and perpendicular to each other. The θ stage 12 changes its posture in the rotation direction of the table 15 around the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com