Modular water-cooling structure of motor controller

A motor controller, modular technology, applied in the direction of electrical equipment construction parts, electrical components, cooling/ventilation/heating transformation, etc., can solve the problems of increased design cycle, no maintainability, low replaceability, etc., to achieve Easy to install, easy to replace, high degree of standardization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

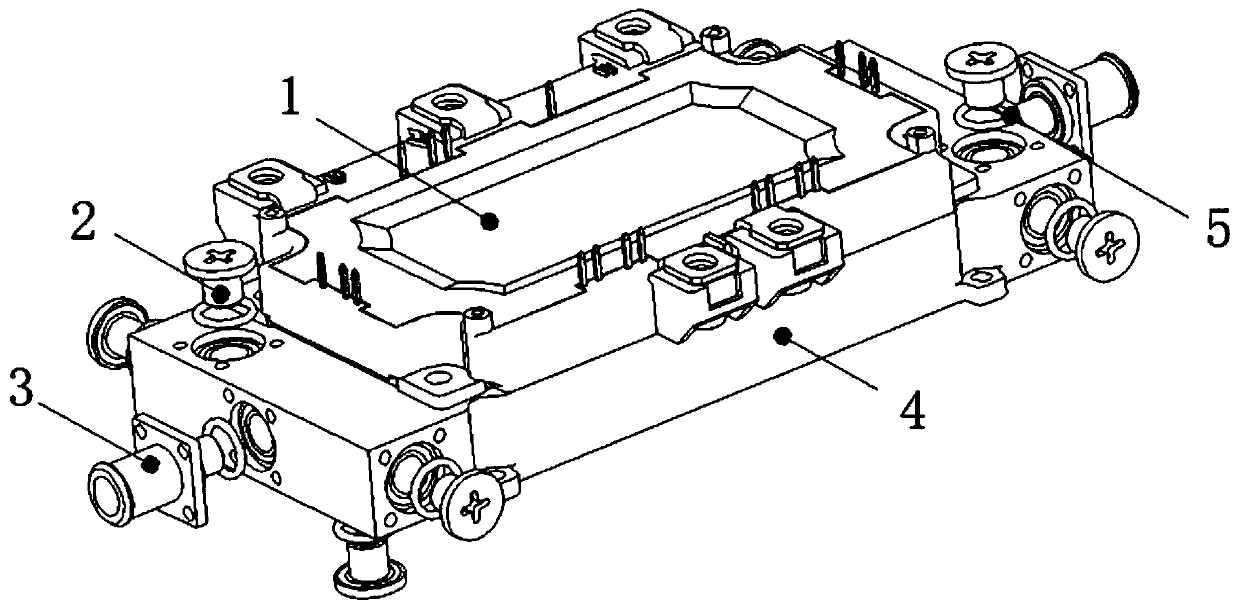

[0029] Such as figure 1 As shown, the motor controller modular water-cooling structure of the present invention includes an IGBT module 1, a sealing screw 2, a water joint 3, a modular water-cooling plate 4 and a sealing ring 5; the IGBT module 1 is fixed by screw locking or welding Installed on the surface of the modularized water-cooled plate 4 for heat dissipation, and then the modularized water-cooled plate 4 is connected and fixed with the housing of the motor controller.

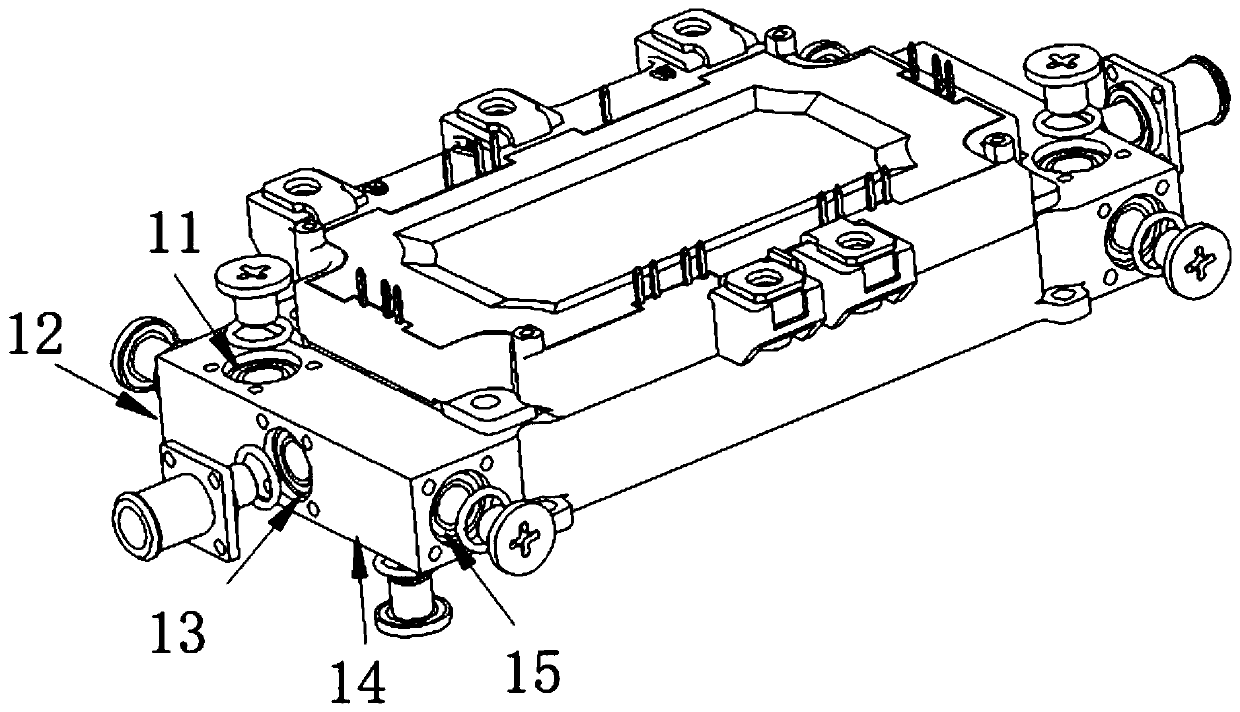

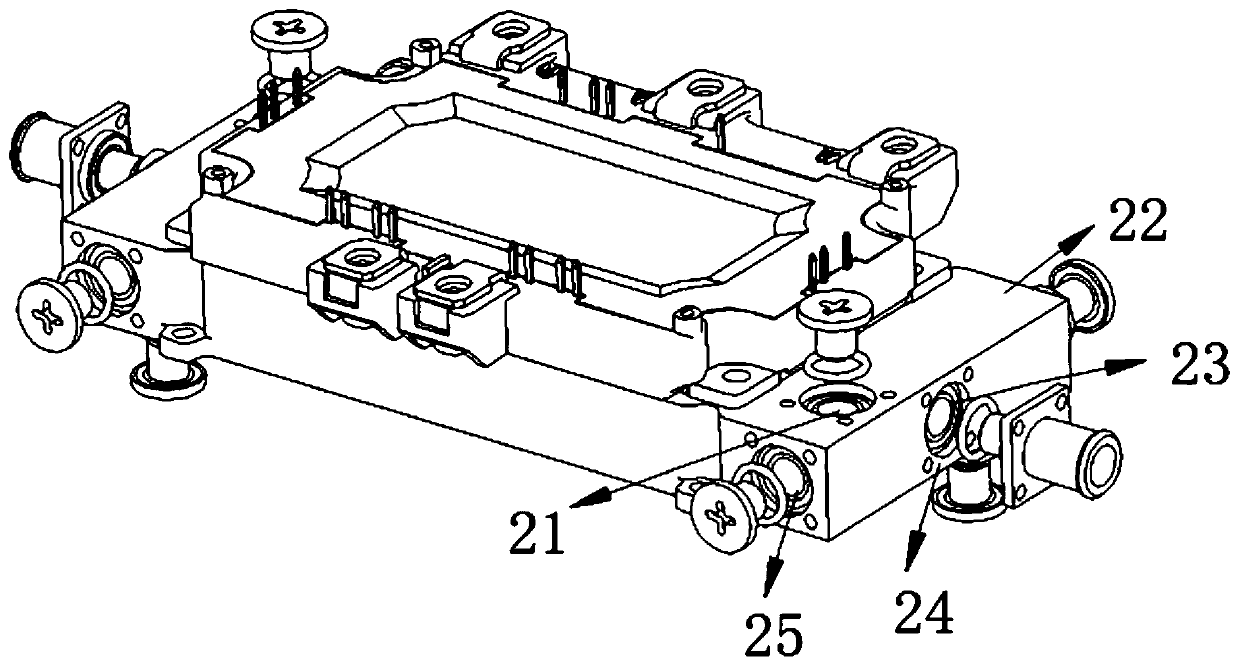

[0030] Such as figure 2 , 3 As shown, one end of the modularized water-cooled plate 4 is provided with five water inlets 11-15 connected with the internal water channel cavity, and the other end is provided with five water outlets 21-25 communicated with the internal water channel cavity; 5 water inlets and 5 water outlets The water outlets are located at the front, rear, upper, lower and end faces of the modularized water cooling plate 4 respectively. In the actual installation process, according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com