Crankshaft, compressor and vehicle

A compressor and crankshaft technology, applied in the compressor, crankshaft, and vehicle fields, can solve problems such as difficult operation, easy occurrence of defects, and inability to adjust eccentricity, and achieve the effect of simple operation and improved versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

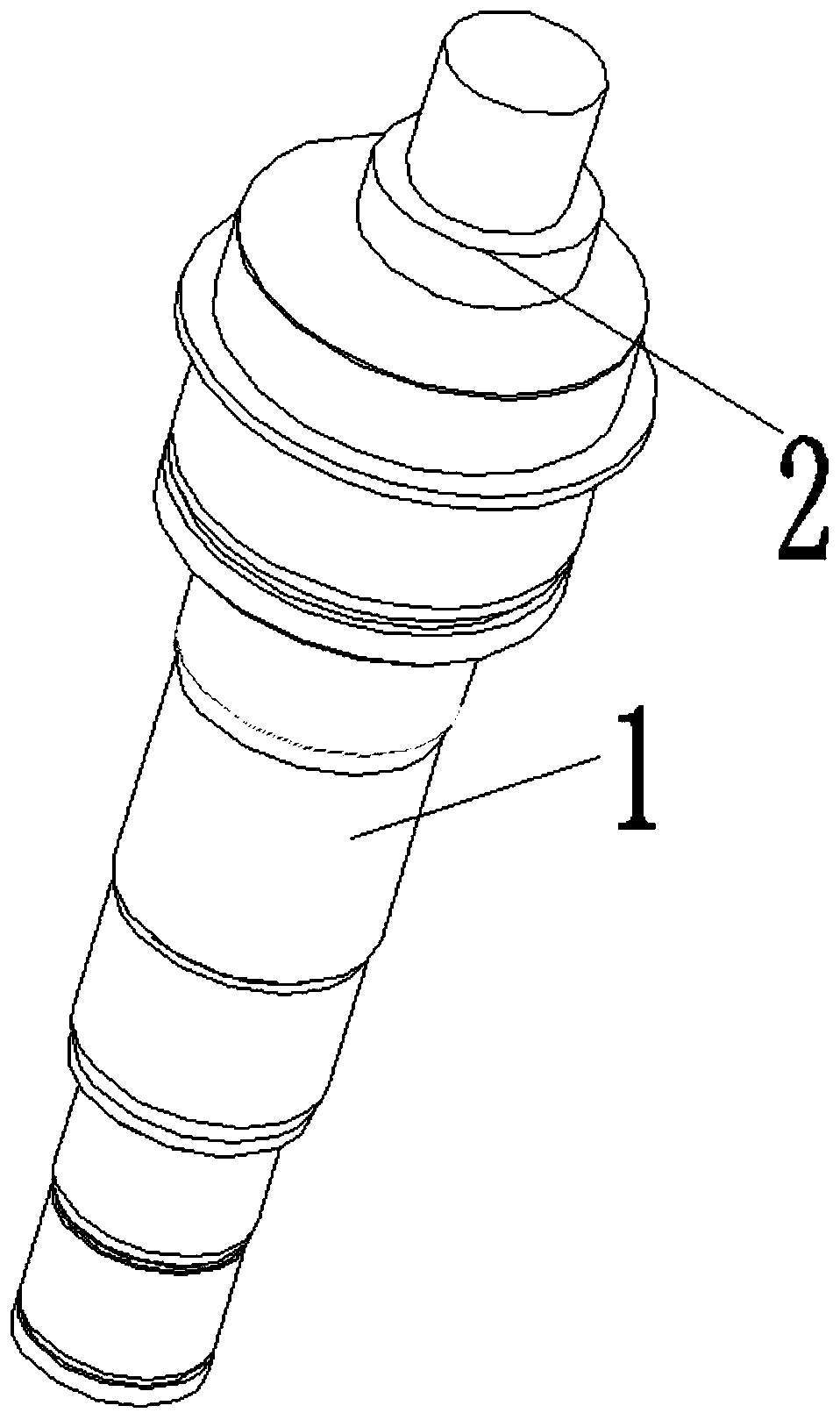

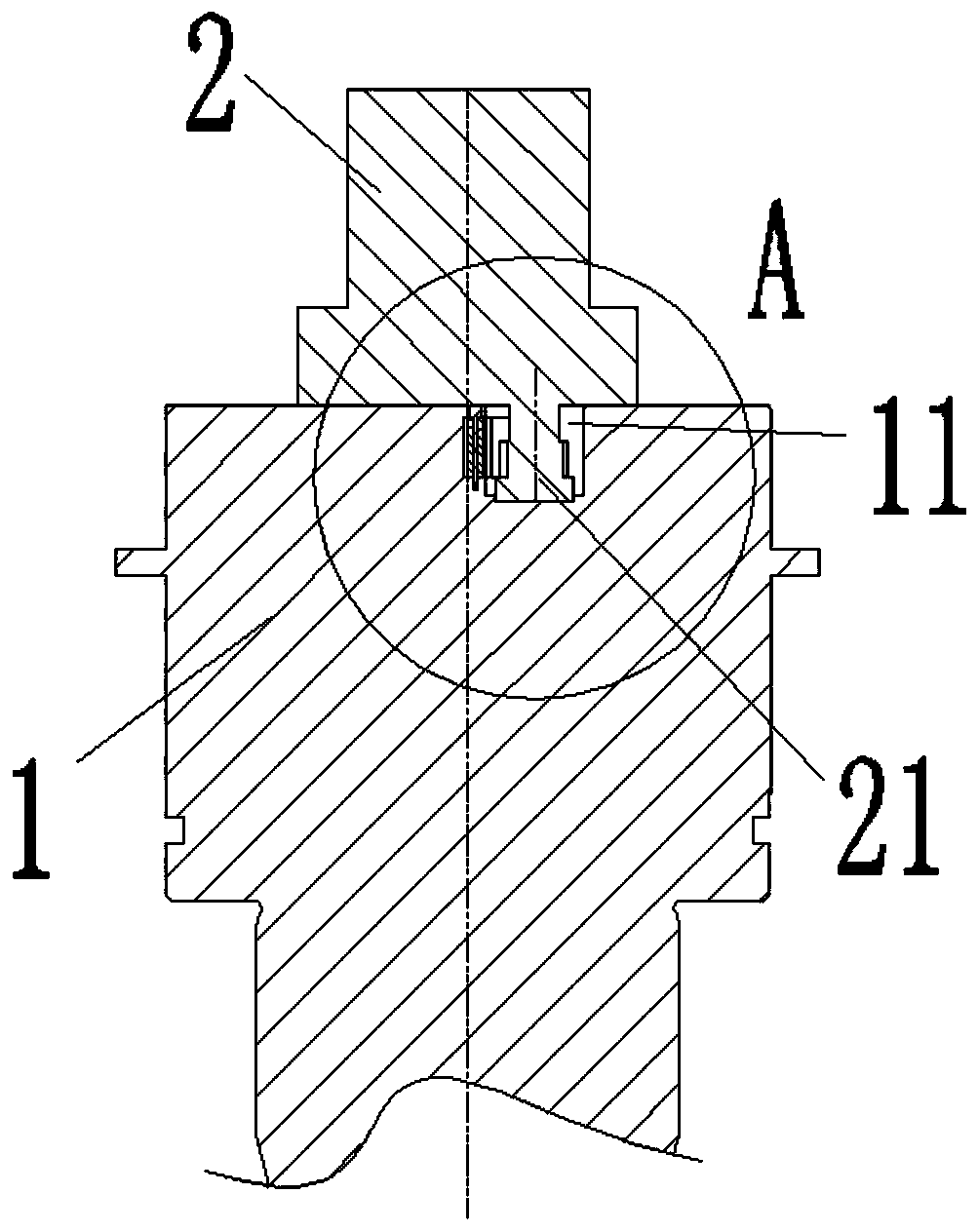

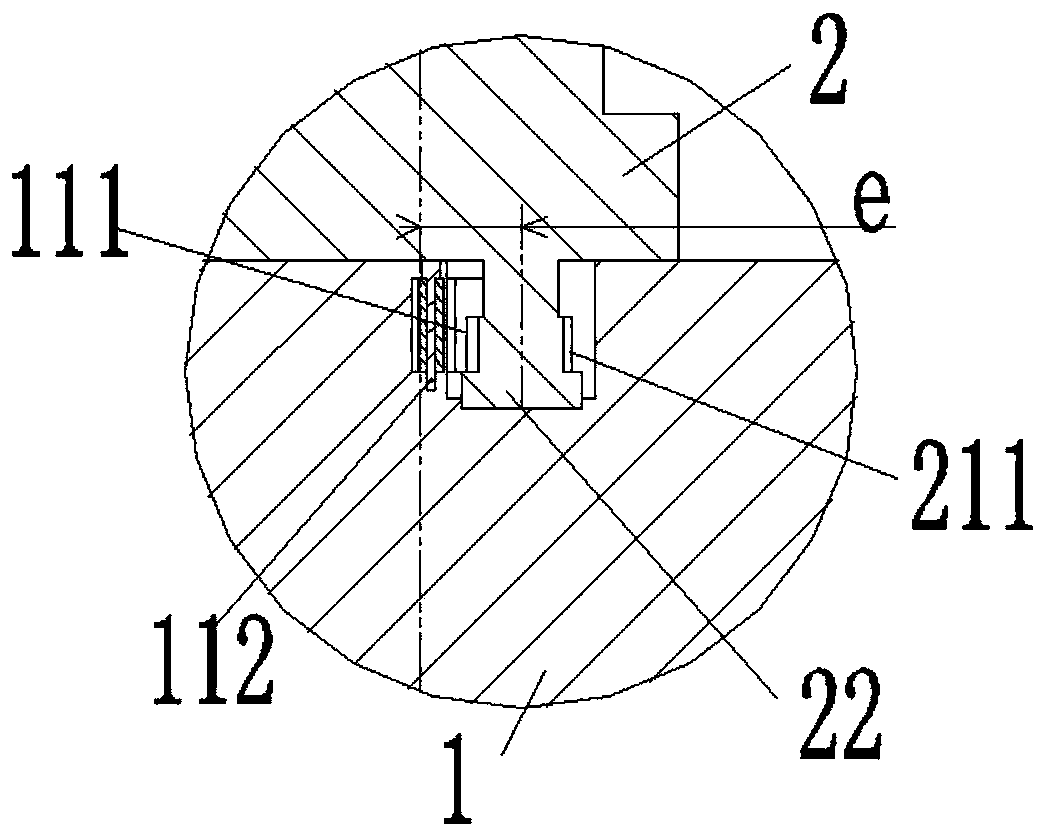

[0027] see in conjunction Figure 1 to Figure 10 As shown, according to an embodiment of the present invention, a crankshaft is provided, including a first shaft body 1 and a second shaft body 2, the first shaft body 1 has a first axis center line, and the first shaft body 1 An eccentric hole 11 deviated from the first axis line is configured on one end surface, and the second shaft body 2 has a second axis line. The eccentric column 21 of the axis line, the eccentric column 21 is inserted into the eccentric hole 11, and there is a one-way rotation limiting mechanism between the eccentric column 21 and the eccentric hole 11, and the one-way rotation limiting mechanism The positioning mechanism is used to ensure that the eccentric post 21 rotates in a first rotation direction relative to the eccentric hole 11, and cannot rotate in a second rotation direction opposite to the first rotation direction. It can be understood that the The first rotation direction is also the normal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com