Double-working-condition rotating wheel dehumidifier

A rotary dehumidifier and dual-working-condition technology, which is applied in household heating, lighting and heating equipment, household heating, etc., can solve problems such as energy waste and achieve energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

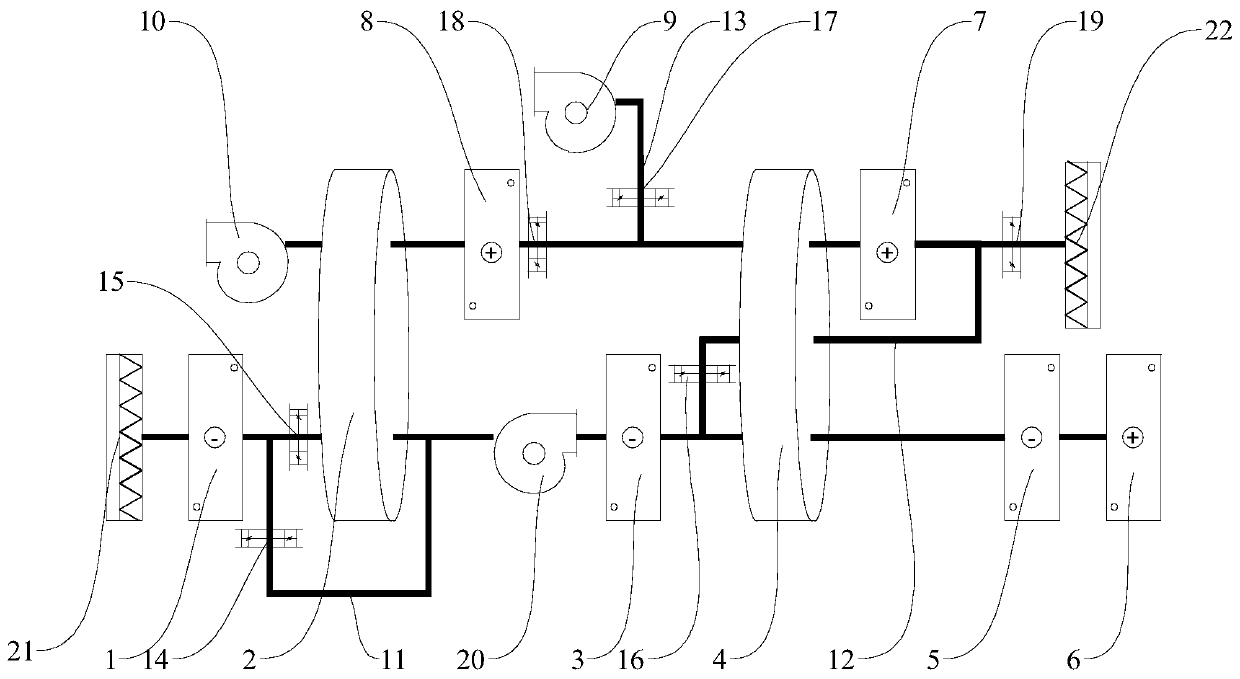

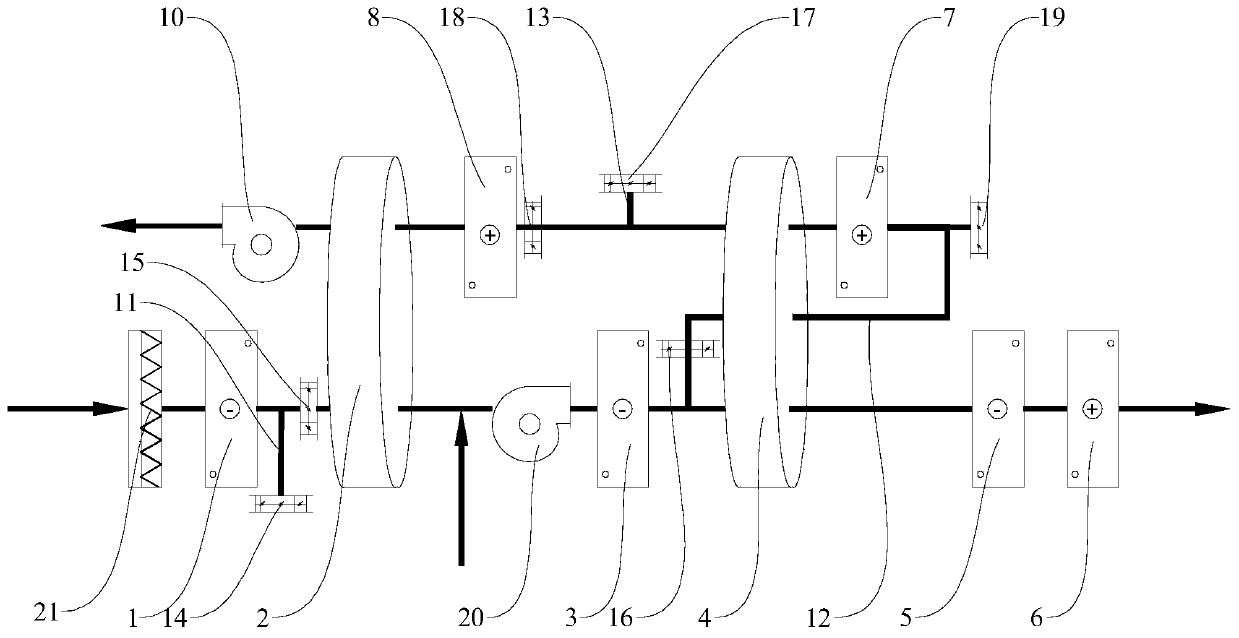

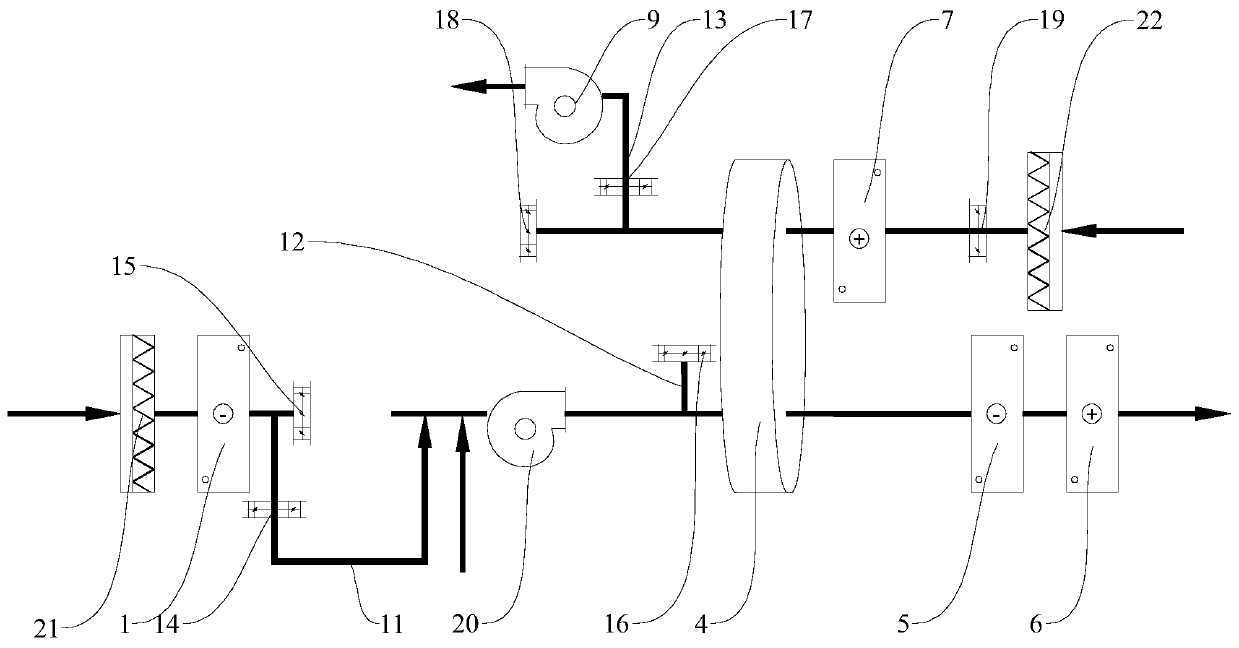

[0044] Such as figure 1 As shown, the double-working condition rotary dehumidifier of this embodiment includes a fresh air surface cooler 1, a first runner 2, a middle surface cooler 3, a second runner 4, a supply air surface cooler 5, and a supply air heating plate Pipe 6, second regenerative heating coil 7, first regenerative heating coil 8, second fan 9, first fan 10, first branch pipe 11, second branch pipe 12, third branch pipe 13, first damper 14, The second air valve 15, the third air valve 16, the fourth air valve 17, the fifth air valve 18, the sixth air valve 19, the mixing fan 20, the first filter 21 and the second filter 22, the first runner 2 has a first treatment zone and a first regeneration zone, and the second runner 4 has a second treatment zone, a second regeneration zone and a regeneration preheating zone. One end of the first branch pipe 11 is connected between the fresh air surface cooler 1 and the first treatment area, the other end of the first branch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com