Double-hinge type electrostatic suspension probe structure

An electrostatic levitation and hinged technology, applied in optics, instruments, optomechanical equipment, etc., can solve problems such as the inability to balance the gravity of the suspended probe, the deformation of the hinge, and the inability to guarantee the verticality of the probe and the hinge in a free state. Make up for angular deflection and mechanical rigidity requirements, and achieve high photolithographic precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] specific implementation plan

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the scope of protection of the present invention is not limited to the following embodiments.

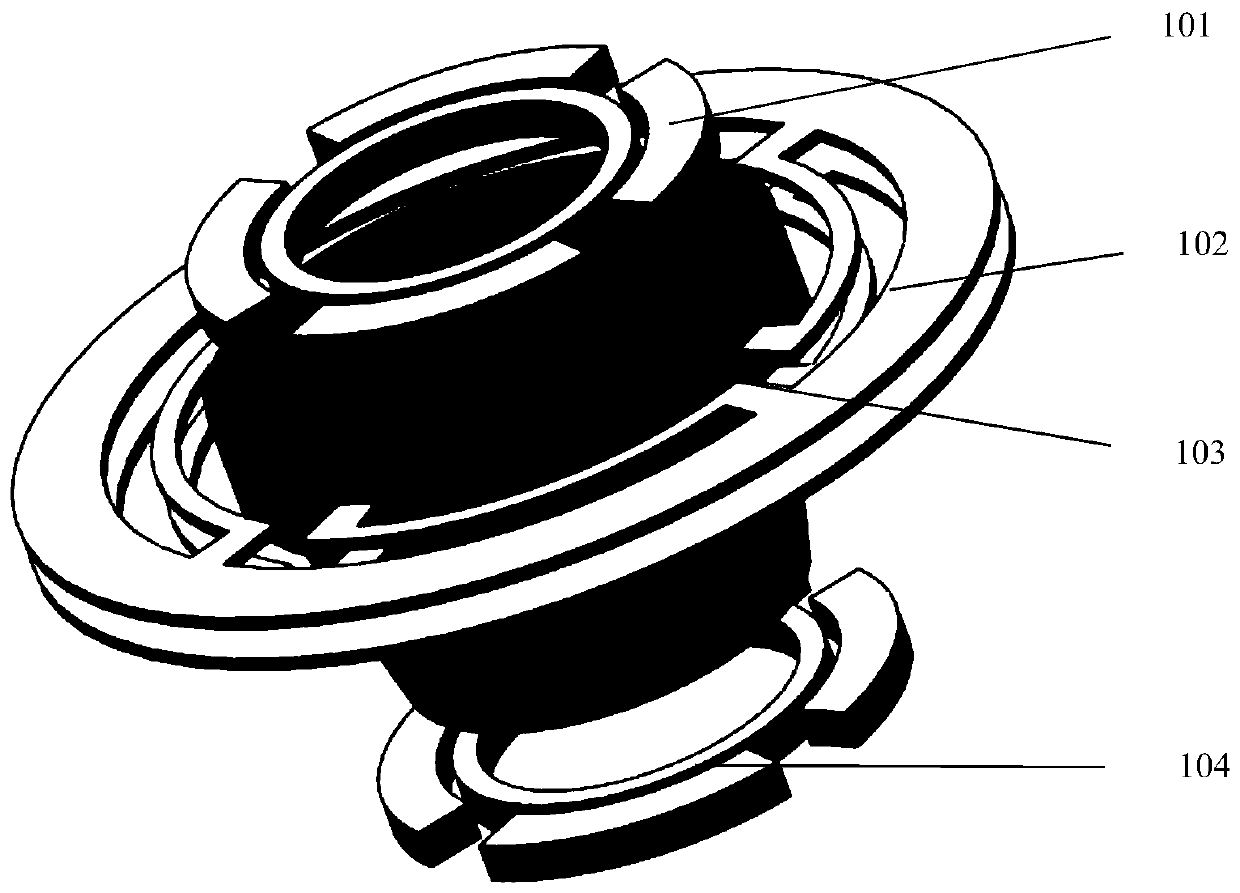

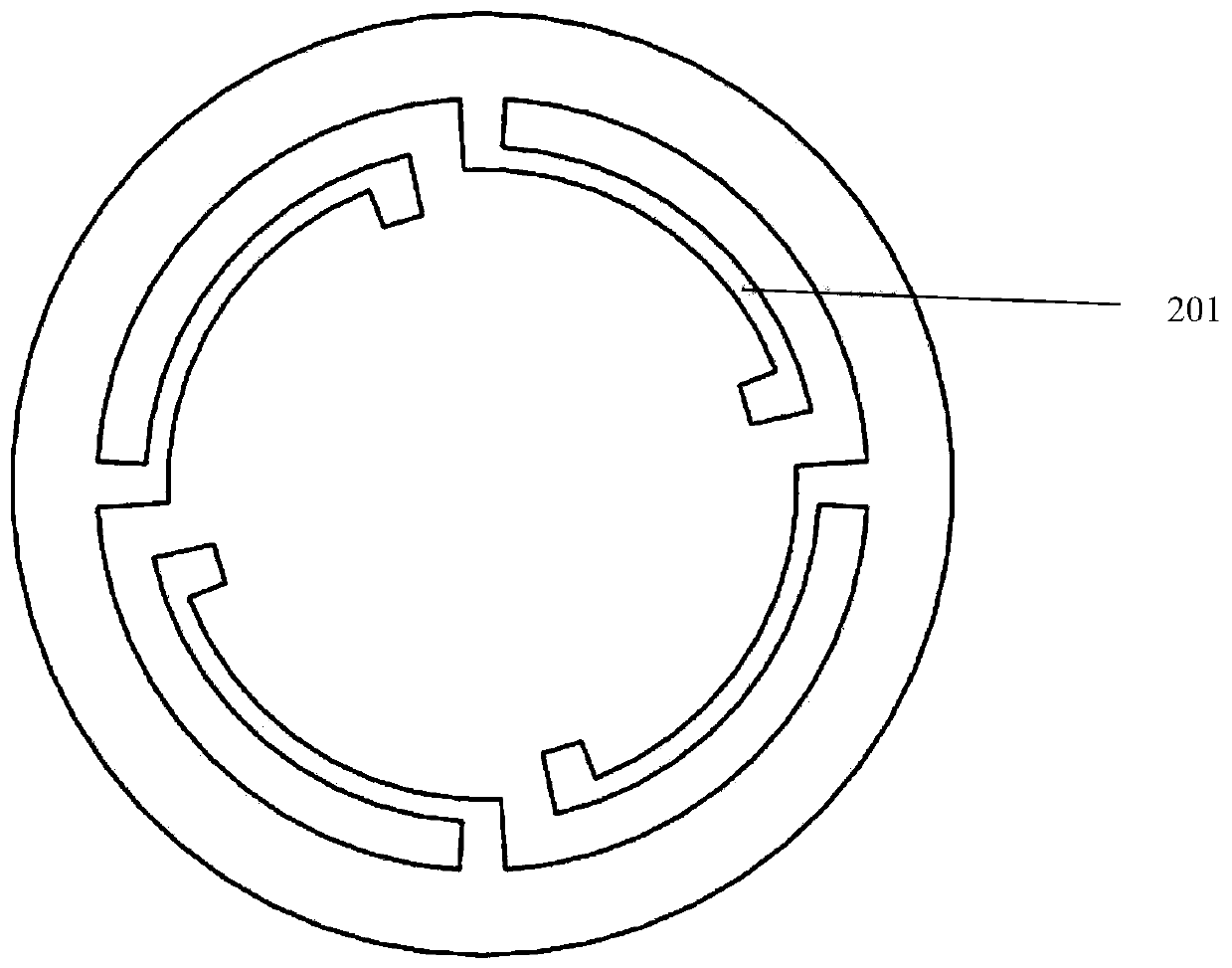

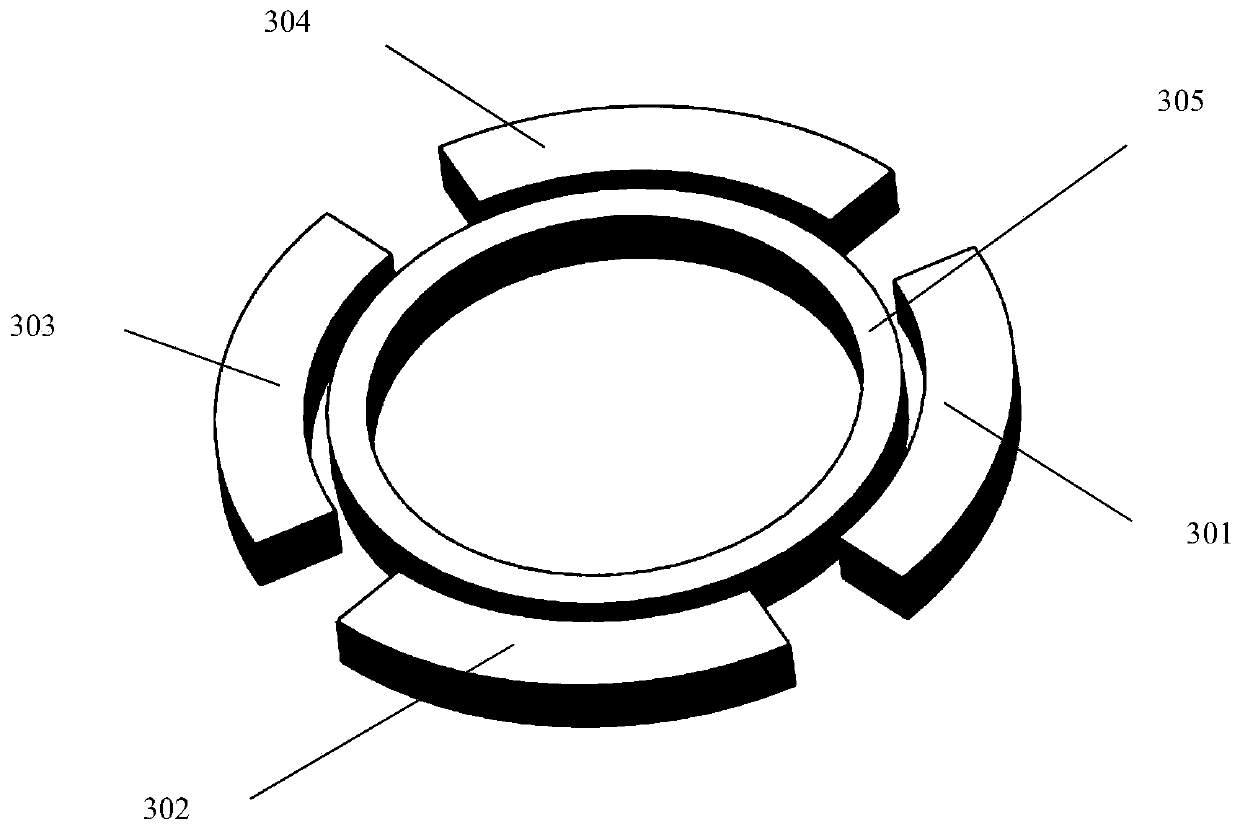

[0018] Such as figure 1 , 2 , 3, and 4, when the lithography machine is not working, the suspended probe (103) will make the suspended probe (103) balance and rest on the silicon wafer under the action of the amphoteric hinge layer (102) and its own gravity And there are micro-pitch positions, and in a static state, the position of the suspended probe (103) is zero at this time. Before the photolithography machine is used, the suspension probe (103) is pre-leveled by using the ring common electrode (305), so that the suspension probe (103) is balanced at the initial working position. The five degrees of freedom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com