Steel plate shape quality anomaly detection method based on CART decision tree

A steel plate shape and anomaly detection technology, applied in the direction of instrumentation, calculation, character and pattern recognition, etc., can solve the problems of frequent misclassification, no quantitative standard, affecting efficiency and product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

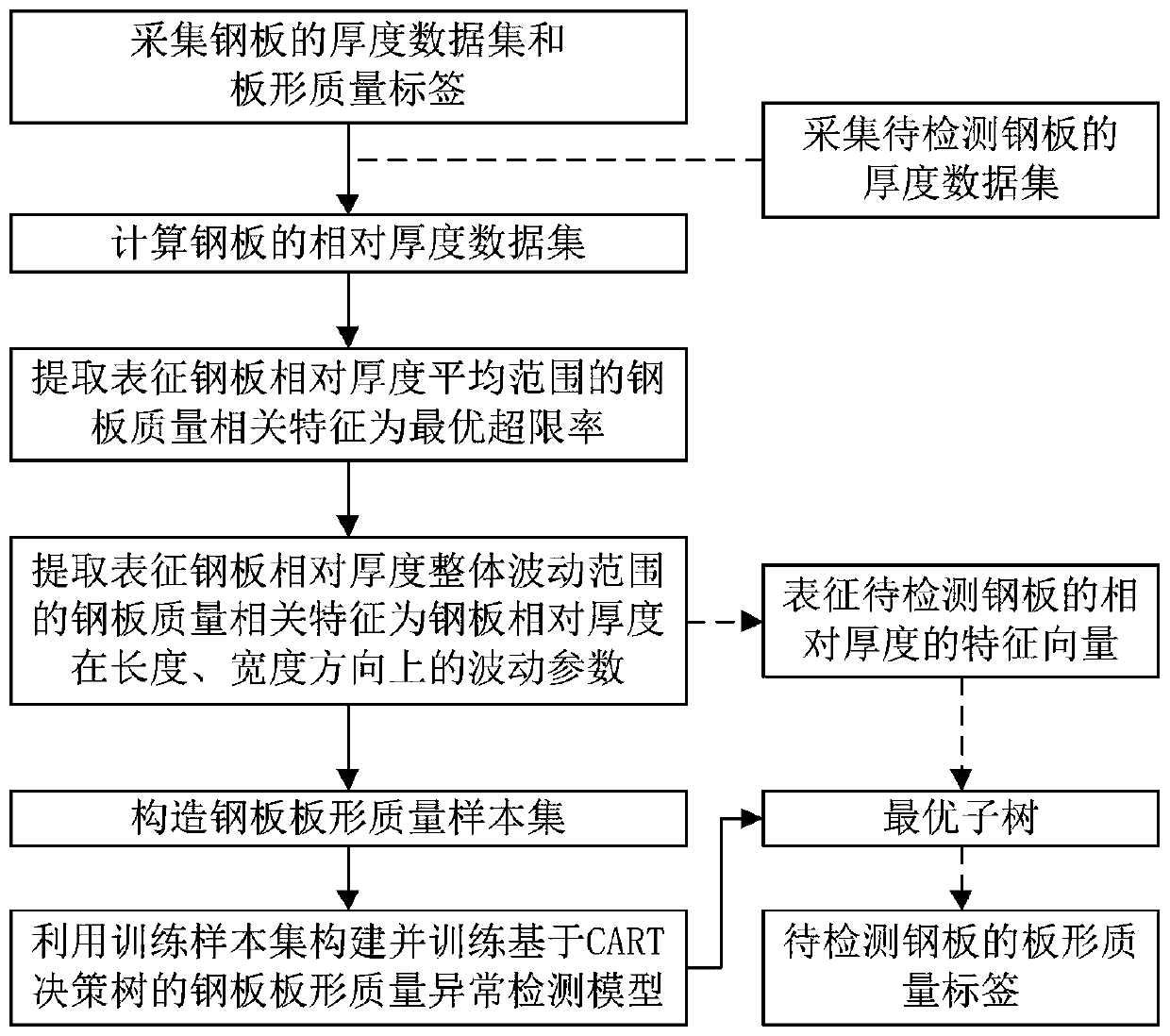

[0057] like figure 1 Shown, the abnormality detection method of steel plate shape quality based on CART decision tree of the present invention, comprises the following steps:

[0058] Step 1: Data collection: Sampling and measuring the thickness of the kth steel plate after the shear line, and obtaining the thickness data set of the kth steel plate as A k ={a k (i,j),i∈{1,2,...,M},j∈{1,2,...,N k}}, and collect the shape quality label y of the kth steel plate k ;

[0059] Among them, k∈{1,2,...,K}, K is the total number of steel plates, a k (i, j) is the thickness of the kth steel plate at the sampling point (i, j), i is the serial number of the sampling point in the width direction of the steel plate, j is the serial number of the sampling point in the longitudinal direction of the steel plate, M is the thickness of the sampling point in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com