Acoustic calibration array for tanks and vessels

A container, acoustic technology, applied in the field of acoustic measurement of container geometry in a non-destructive manner, capable of solving the problems of tank volume errors, cost, few tank corrections/measurements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

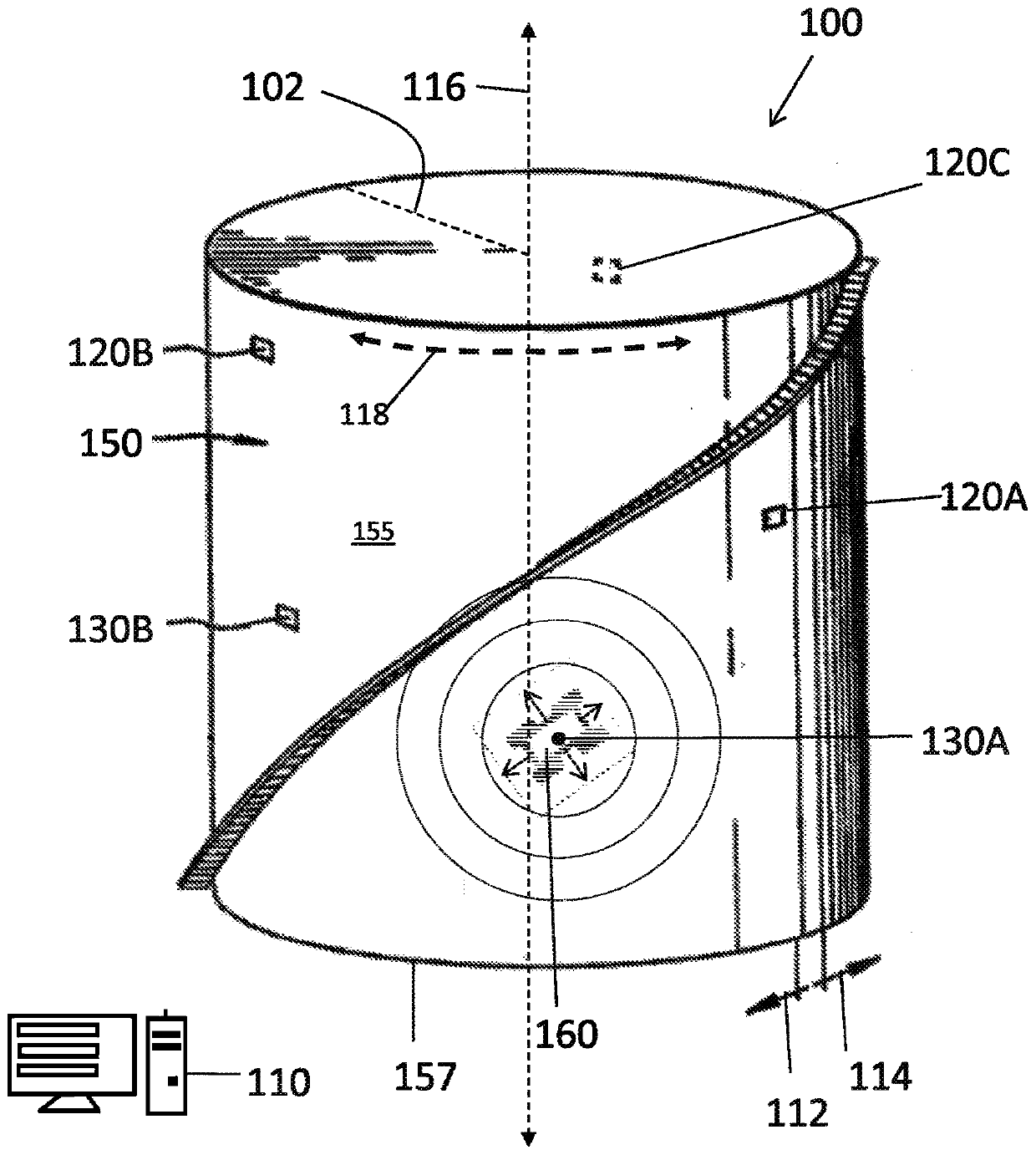

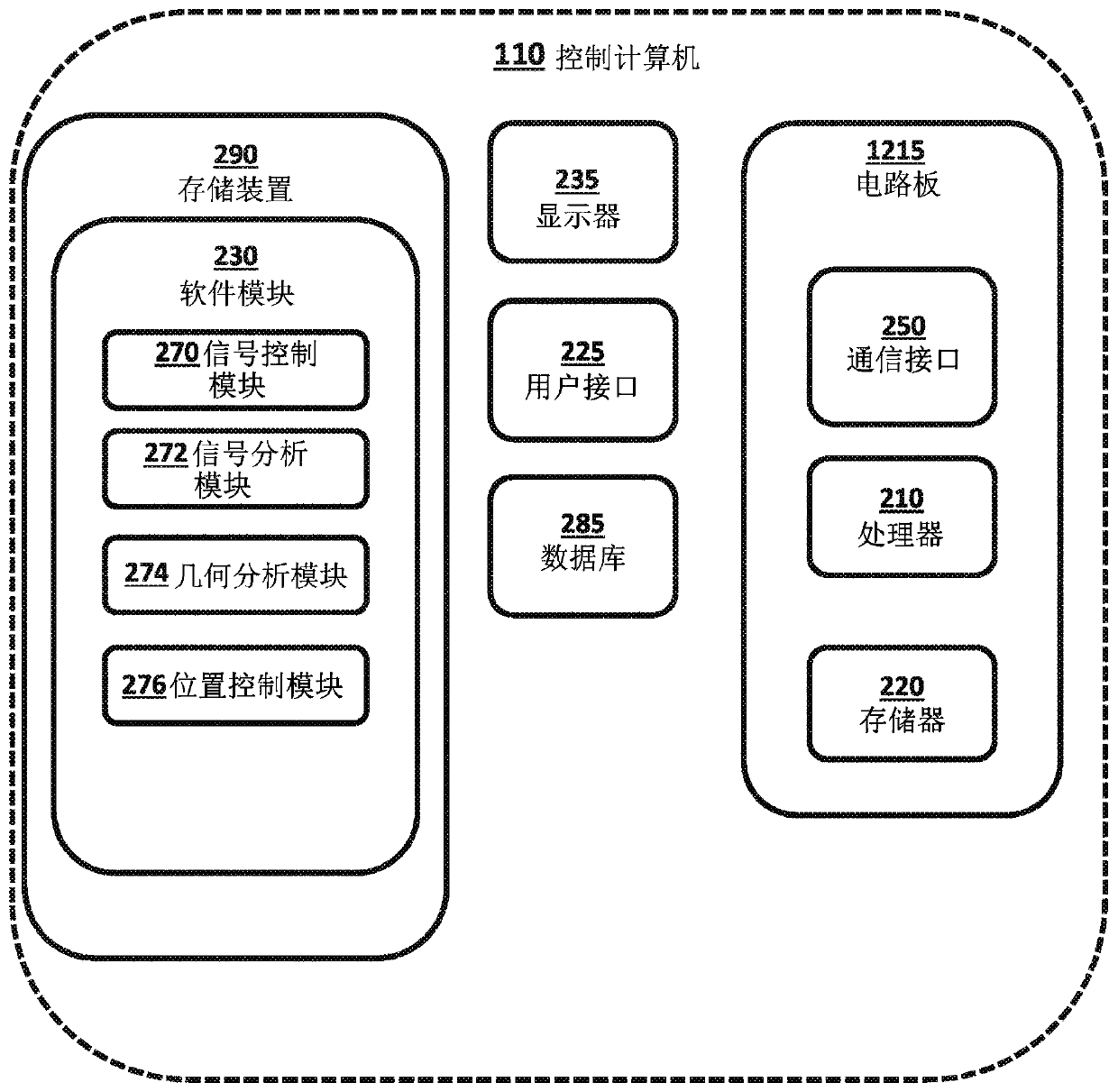

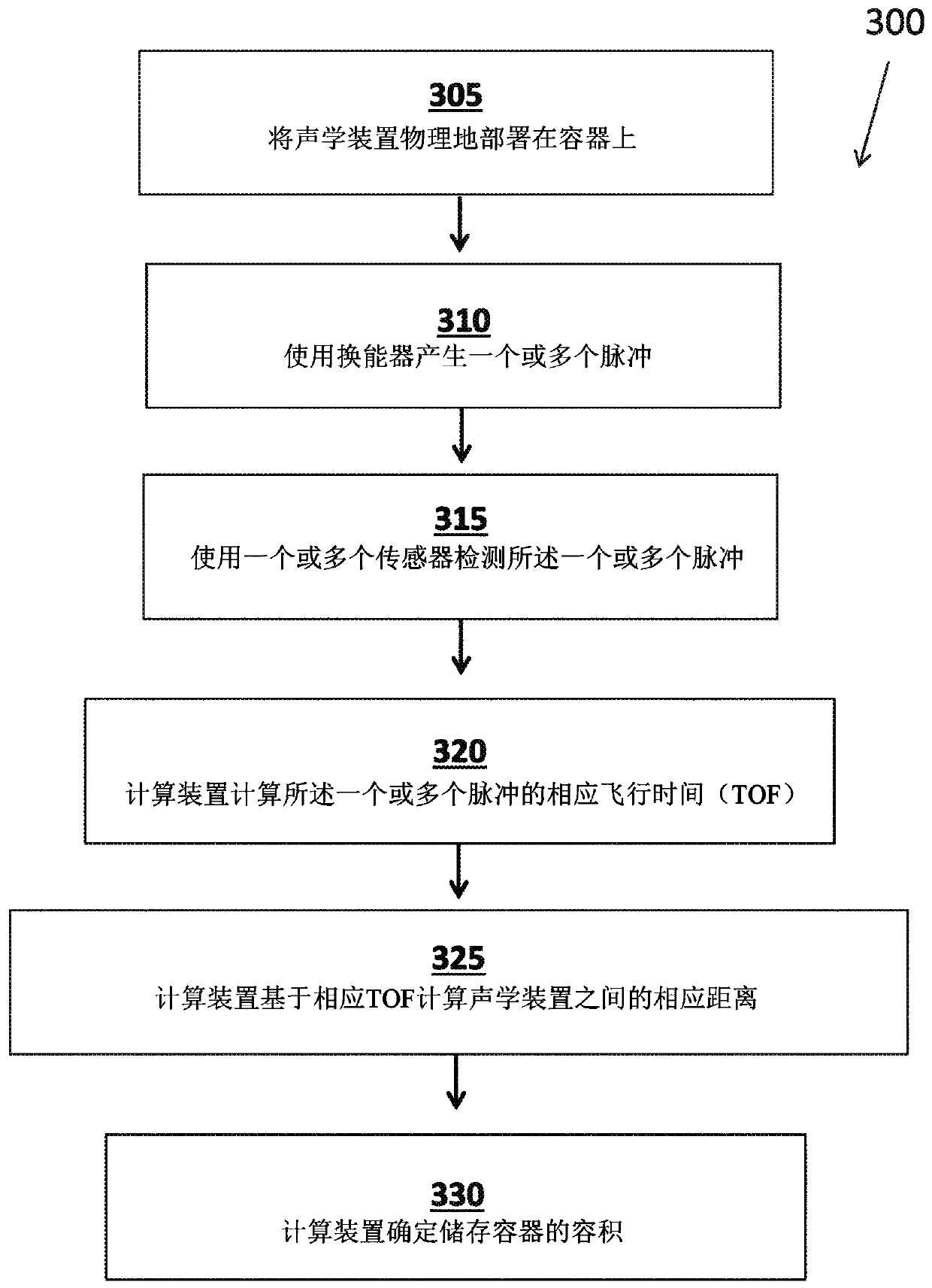

[0032] By way of overview and introduction, a system and method for calibrating the volume of a storage container is disclosed. More specifically, the systems and methods disclosed herein relate to measuring and dimensioning large petroleum storage tanks using sonic or more generally mechanical wave based inspection techniques to calculate the volume of such tanks. Preferably, the system is configured to perform corrections from outside the container as needed during use of the container in the field.

[0033] Acoustic testing is a non-destructive and non-invasive testing technique based on the analysis of the propagation of sound waves in the material under test (eg, container walls). In the embodiments described herein, the measurement technique is performed to measure the volume of a large storage container that is generally generally cylindrical in shape and typically made of steel or other metals and alloys. However, the disclosed techniques and systems may also be appli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com