Anti-sticking paint blending device

An anti-sticking wall and paint technology, applied in the field of paint toning, can solve the problems of uneven paint toning, reduce labor intensity of workers, etc., and achieve the effects of increasing the mixing range, ingenious structural design, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

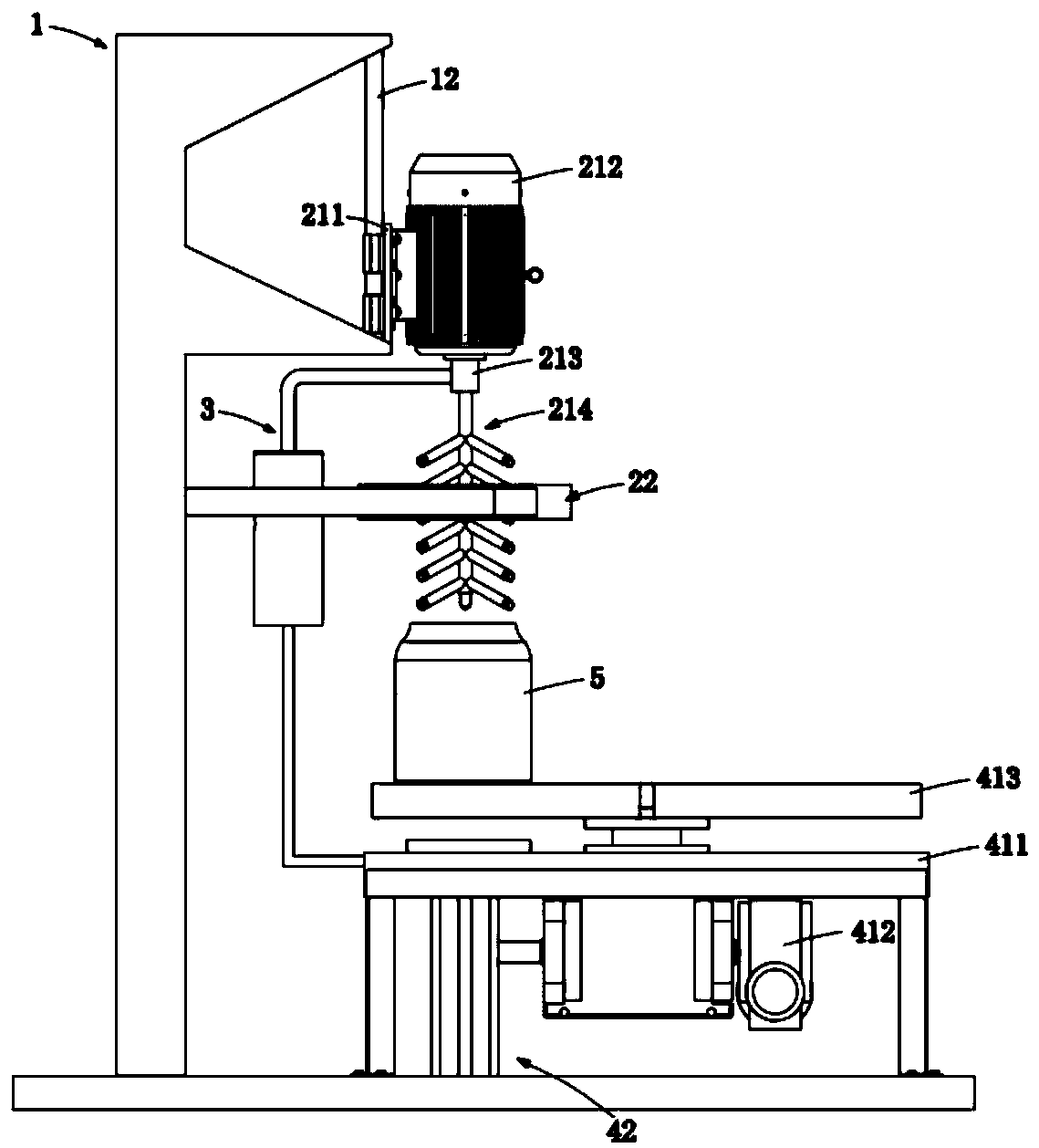

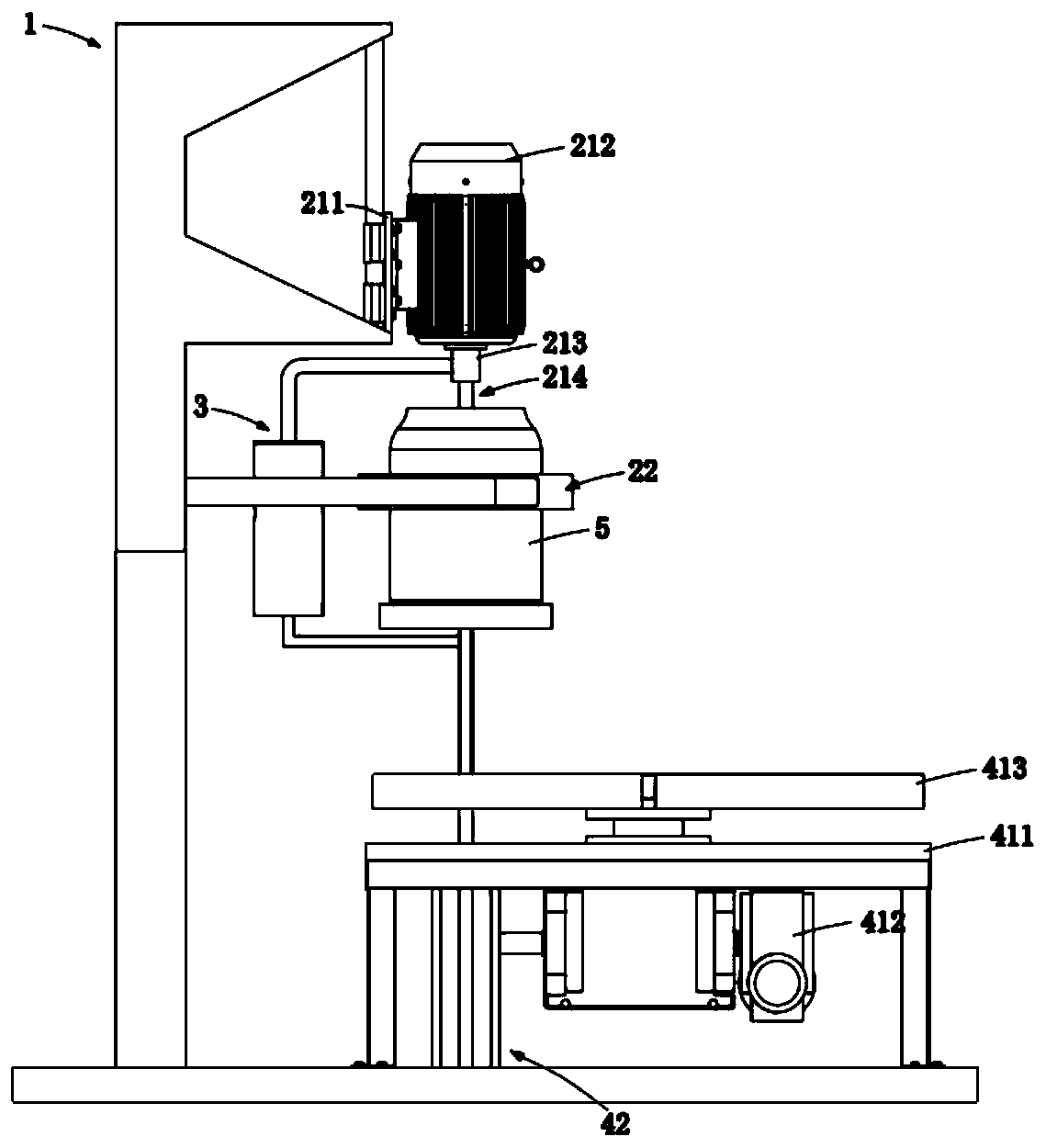

[0047] Such as Figure 1 to Figure 17 Shown, the paint blending device of anti-adhesion wall is characterized in that, comprising:

[0048] A frame 1, the upper end of the frame 1 is symmetrically provided with guide rails 11;

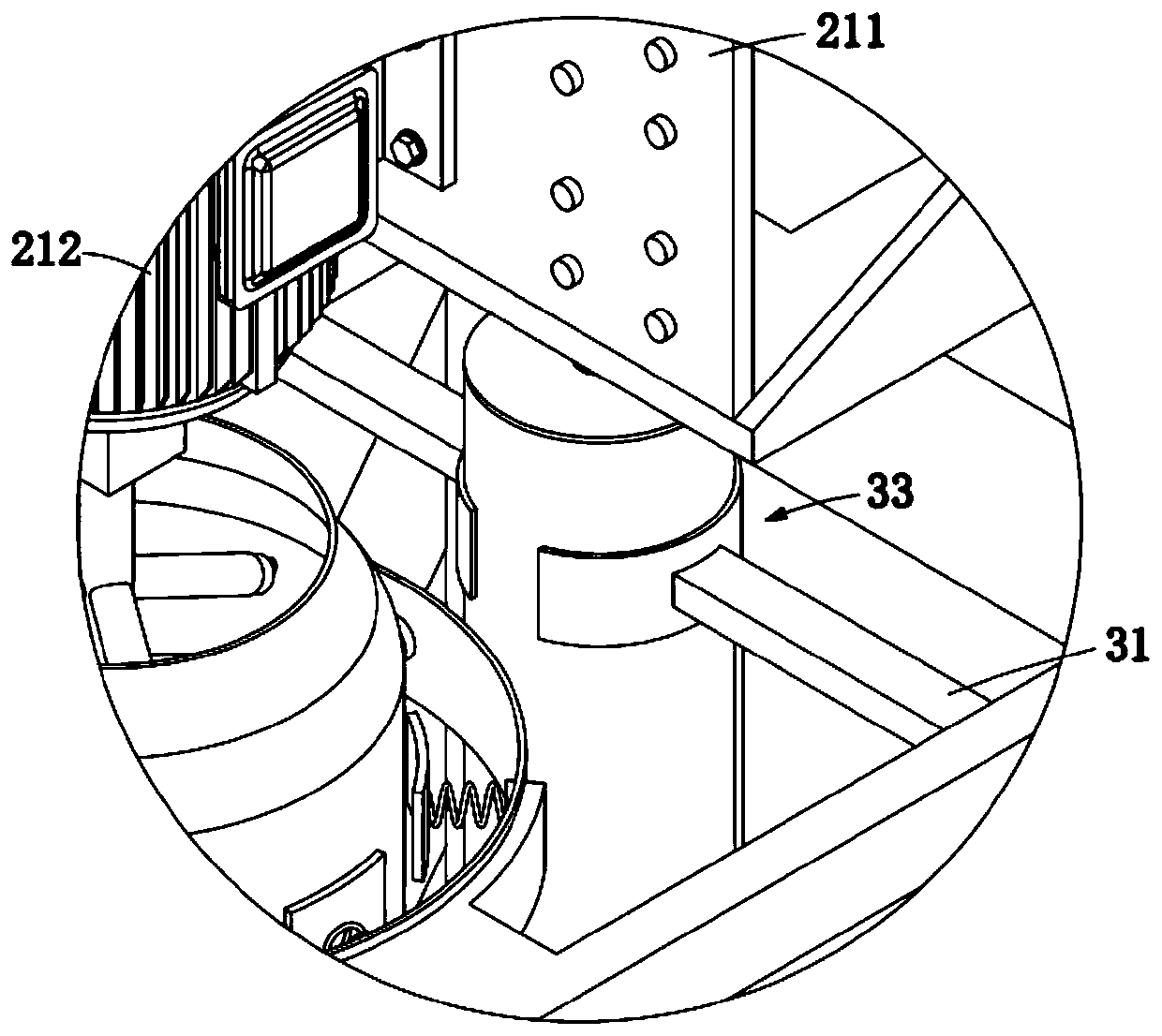

[0049] Stirring part 2, described stirring part 2 comprises the stirring assembly 21 that is arranged on the guide rail 11 and the paint bucket limit assembly 22 that is arranged below described guide rail 11 and is installed on frame 1, and described stirring assembly 21 includes The plate 211 is slidably installed on the guide rail 11 and the vertically arranged stirring motor 212, the air collecting cavity 213 arranged at the output end of the stirring motor 212, and the stirring mechanism 214 arranged at the output end of the stirring motor 212; 22 includes two support frames 221 symmetrically installed on the frame 1, an annular limit frame 222 installed between the two support frames 221 and coaxial with the stirring mechanism 214, and equidista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com