Separated boxing production method

A production method and packaging box technology, applied in the field of split-lane packaging production, can solve problems such as correction of food that cannot be bagged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

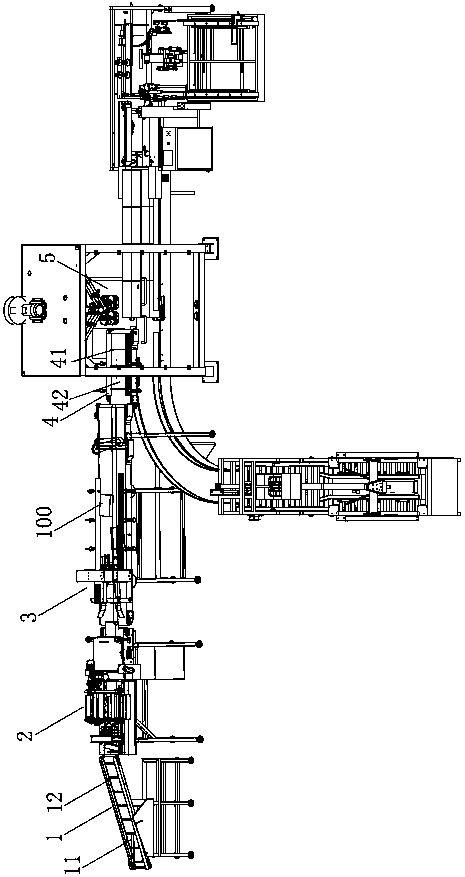

[0055] Such as Figure 1-Figure 3 Shown, a kind of lane packing production method comprises the steps:

[0056] Step 1, carrying out horizontal package rejection and upside-down compaction on the bagged food 100;

[0057] Step 2, realize the orientation correction and lane separation of the bagged food 100 through the continuous swing of the lane-dividing channel;

[0058] Step 3, preliminarily arrange the bagged food 100 after lane separation;

[0059] Step 4, grabbing the preliminarily arranged bagged food 100 into a packing box.

[0060] This application can realize the flattening of the bagged food 100, and reject the bagged food 100 wrapped horizontally, and correct the orientation of the bagged food 100 that is inclined so that it is in a vertically wrapped state as much as possible. At the same time, it can The effect of continuously separating the bagged foods 100 in a single row is realized.

Embodiment 2

[0062] Such as Figure 1-Figure 3 Shown, a kind of lane packing production method comprises the steps:

[0063] Step 1, carrying out horizontal package rejection and upside-down compaction on the bagged food 100;

[0064] Step 2, realize the orientation correction and lane separation of the bagged food 100 through the continuous swing of the lane-dividing channel;

[0065] Step 3, preliminarily arrange the bagged food 100 after lane separation;

[0066] Step 4, grabbing the preliminarily arranged bagged food 100 into a packing box.

[0067] Step 1 is specifically: carrying out horizontal package rejection and upside-down compaction of the bagged food 100;

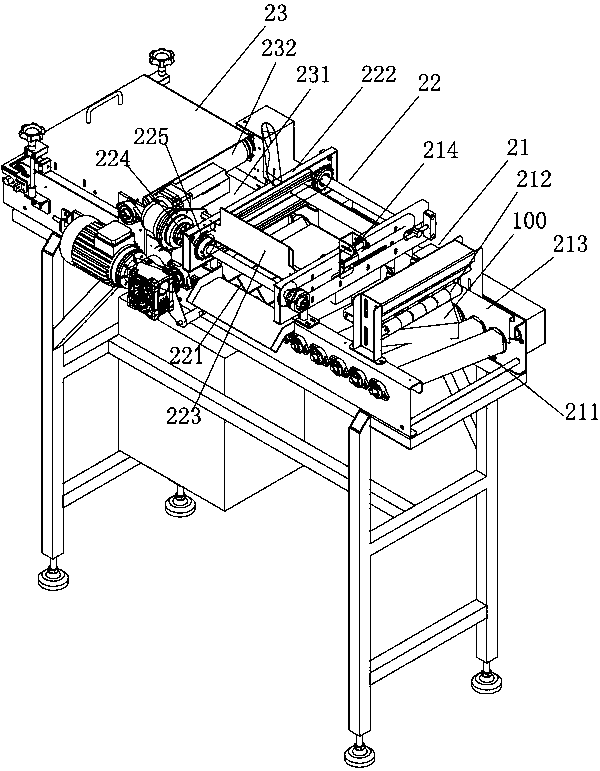

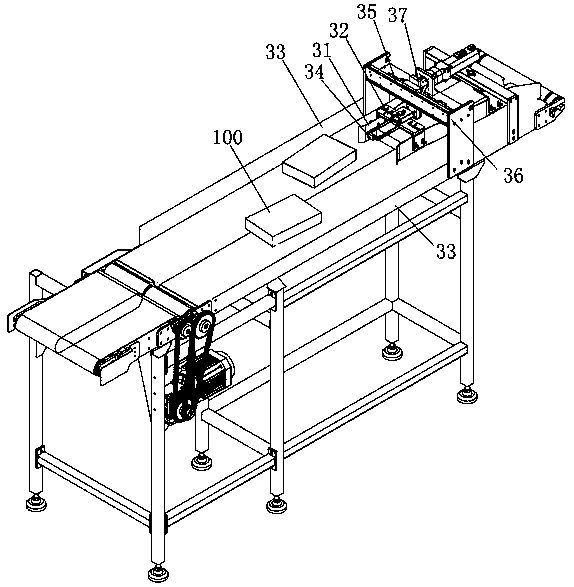

[0068] The bagged food 100 is lightly pressed by the unpowered roller 212 and driven by the inclined roller 211 to the first baffle 213 on one side, and the first photoelectric sensor 214 detects whether there is a horizontal bag according to the preset length difference between the horizontal and vertical bags; the serv...

Embodiment 3

[0076] Such as Figure 1-Figure 3 Shown, a kind of lane packing production method comprises the steps:

[0077] Step 1, carrying out horizontal package rejection and upside-down compaction on the bagged food 100;

[0078] Step 2, realize the orientation correction and lane separation of the bagged food 100 through the continuous swing of the lane-dividing channel;

[0079] Step 3, preliminarily arrange the bagged food 100 after lane separation;

[0080] Step 4, grabbing the preliminarily arranged bagged food 100 into a packing box.

[0081] Step 1 is specifically: carrying out horizontal package rejection and upside-down compaction of the bagged food 100;

[0082] The bagged food 100 is lightly pressed by the unpowered roller 212 and driven by the inclined roller 211 to the first baffle 213 on one side, and the first photoelectric sensor 214 detects whether there is a horizontal bag according to the preset length difference between the horizontal and vertical bags; the serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com