Cutter used for manufacturing drum rack plate

A cutting machine and drum stand technology, which is applied in the direction of manufacturing tools, sawing components, sawing equipment, etc., can solve the problems that the board cannot be kept flat, the rate of cutting defective products is high, and the cutting efficiency is low, so as to achieve consistent size and work efficiency. High, avoid the effect of local warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

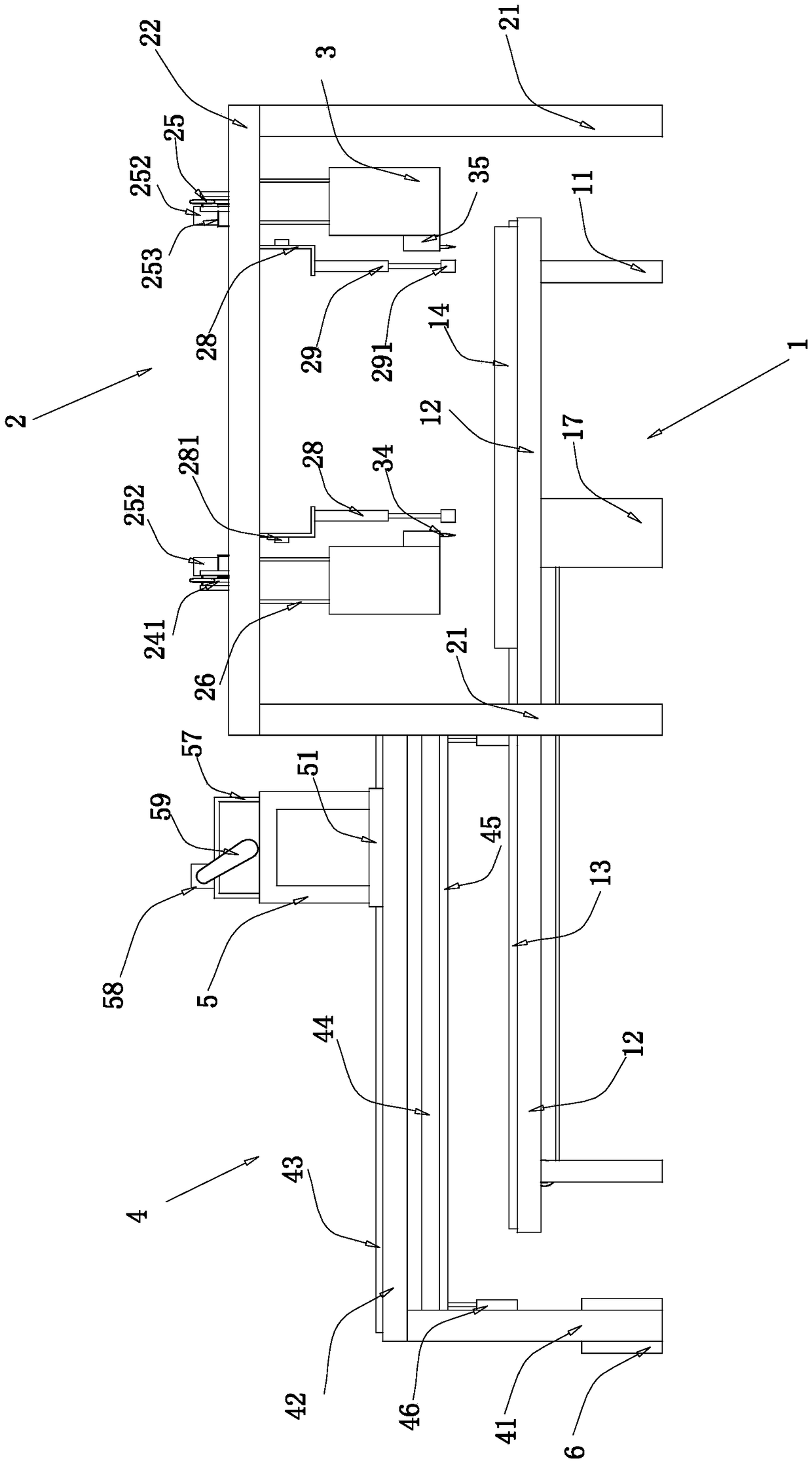

[0036] Such as Figure 1 to Figure 11 As shown, the present invention mainly includes a conveying mechanism 1, an edge trimming mechanism 2, a first flattening mechanism, a second flattening mechanism and a cutting mechanism 4. The present invention will be described in detail below with reference to the accompanying drawings.

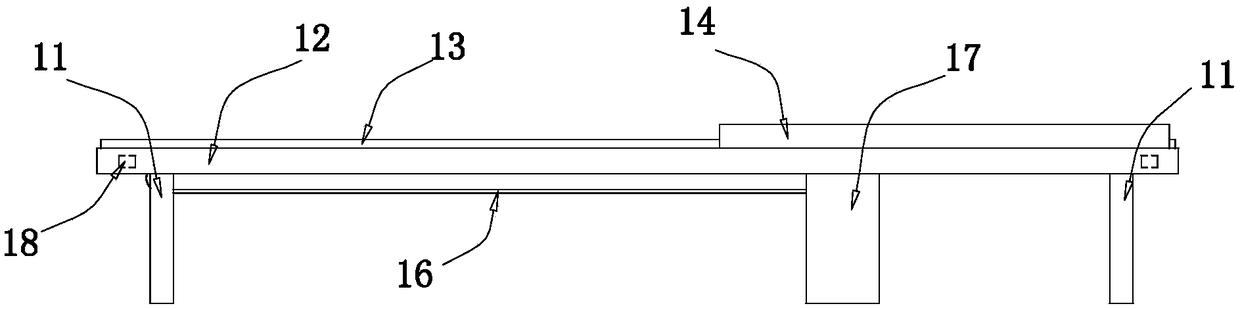

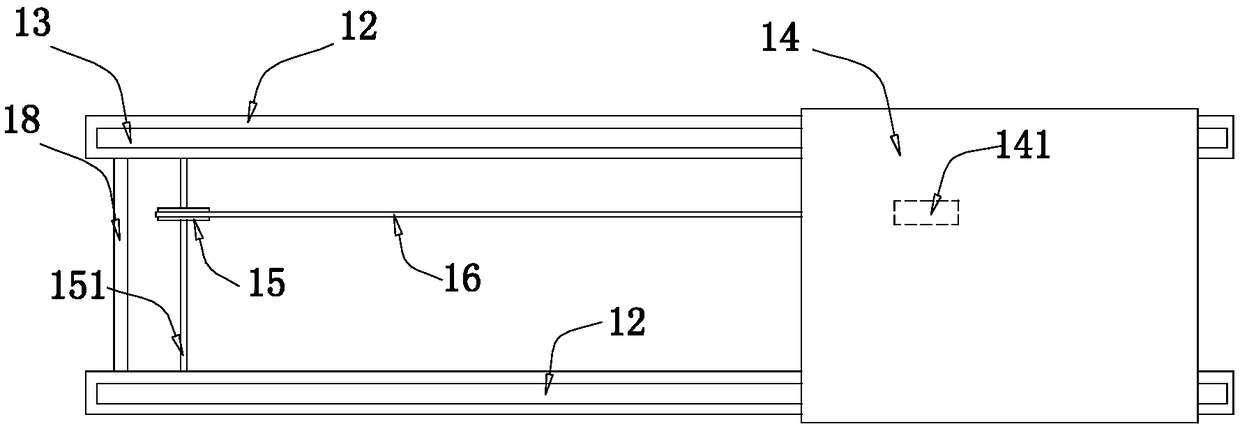

[0037] Such as Figure 1 to Figure 3 As shown, the conveying mechanism 1 mainly includes a first leg 11, a first beam 12, a first guide rail 13, a conveying platform 14 and a driving unit. There are four first legs 11, and the four first legs are respectively located in a rectangular shape. On the four vertices of the front side, a first beam 12 is arranged between the tops of the two first legs on the front side, and the first legs are connected together by the first beam. The front and rear crossbeams are fixedly connected together by the first connecting rod 18, and the first leg, the first crossbeam and the first connecting rod constitute the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com