Auxiliary winding device for chemical fiber fabric production

A winding device and fabric technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems such as the influence of chemical fiber fabric winding quality, and achieve the effect of improving winding quality, safe and convenient use, and tight winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

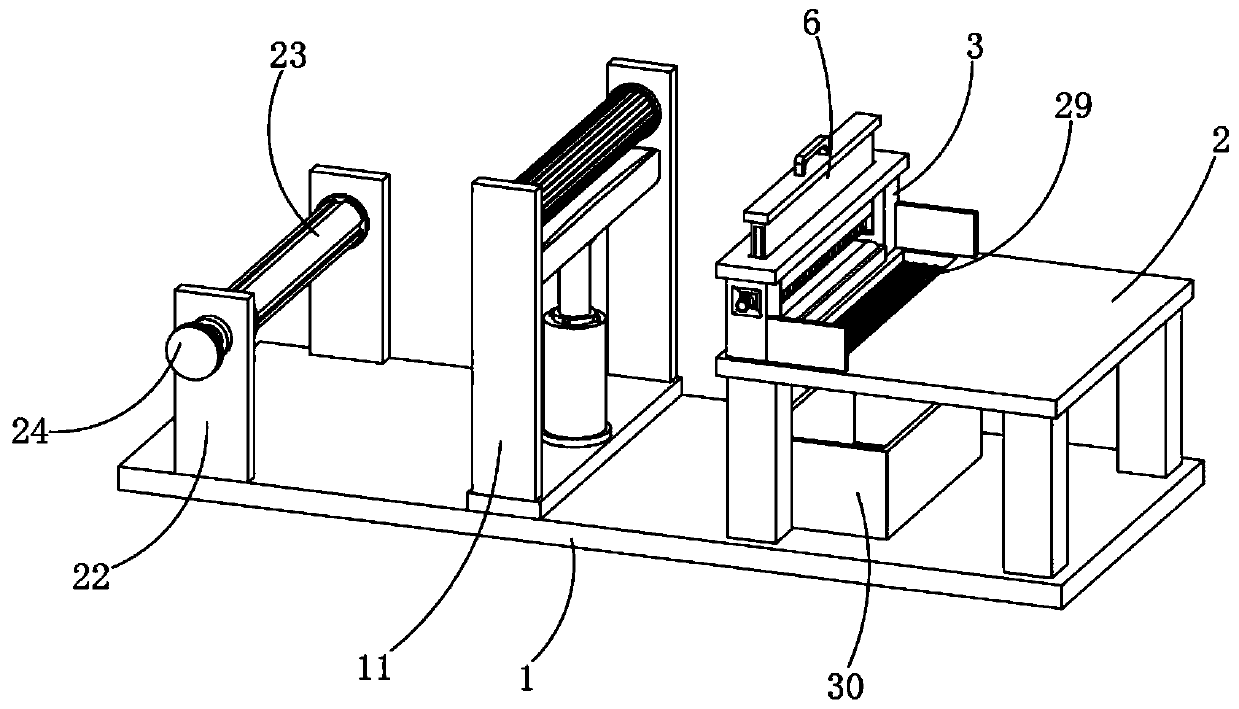

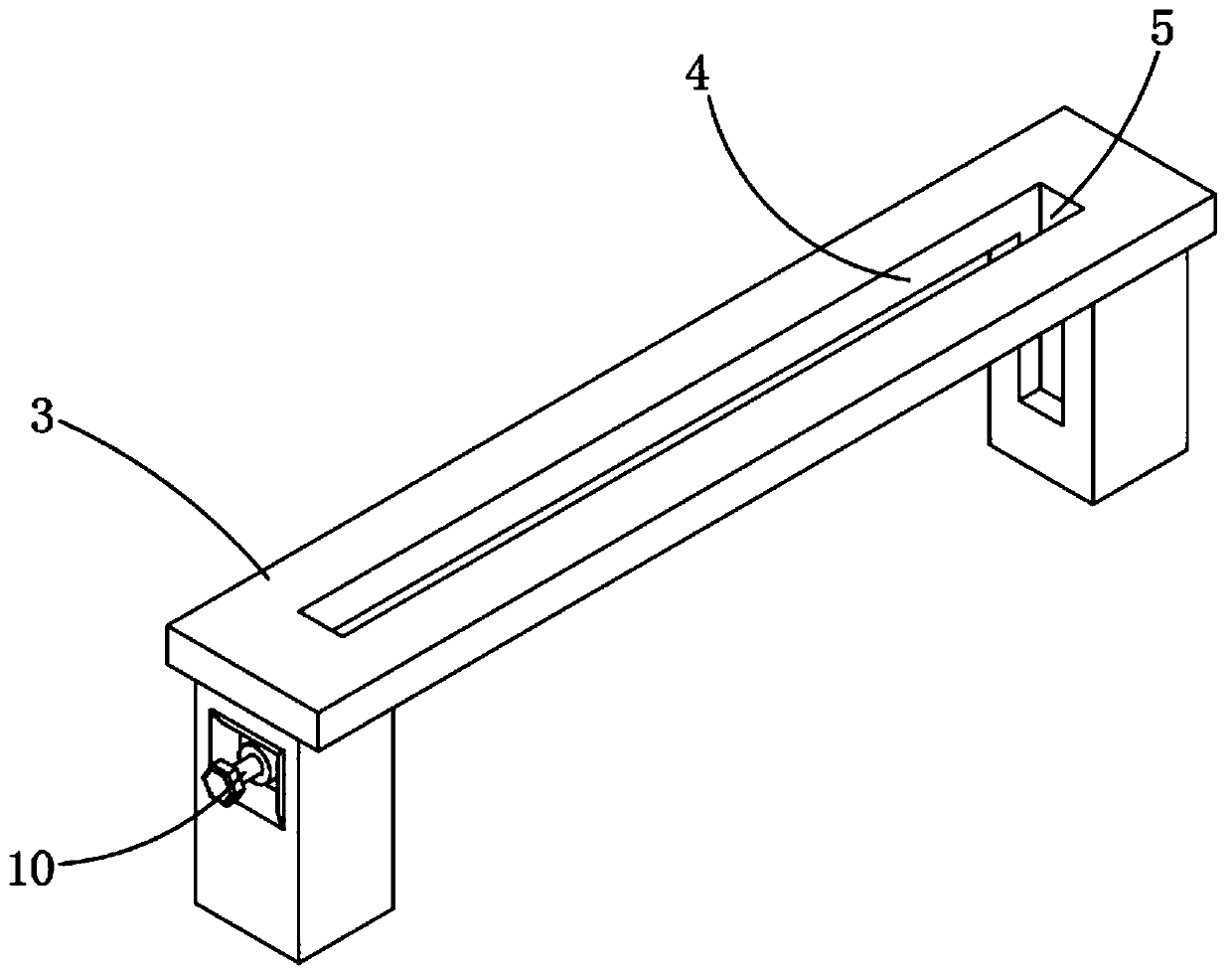

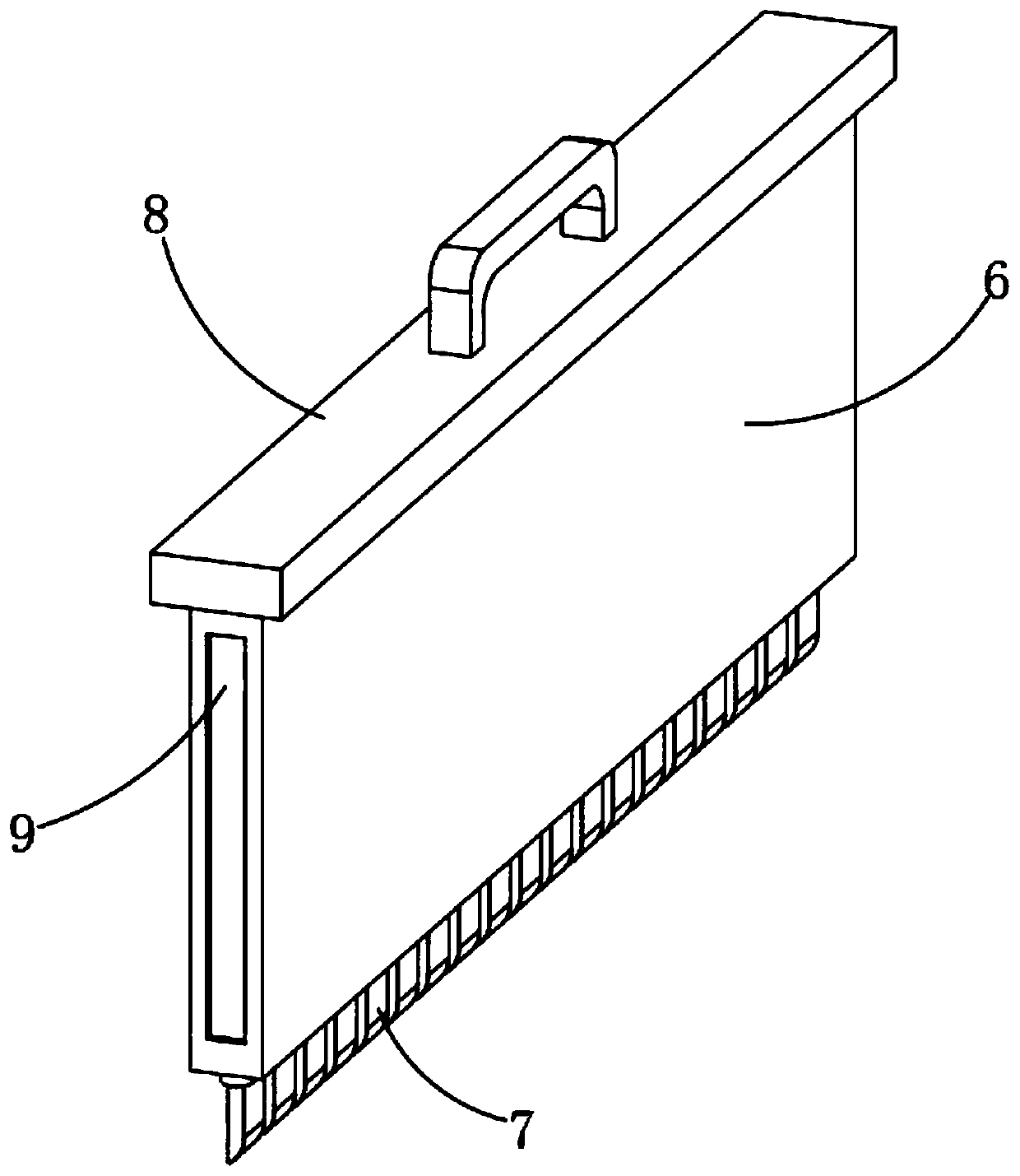

[0026] Example: such as Figure 1-6 As shown, the present invention provides a technical solution, an auxiliary winding device for the production of chemical fiber fabrics, including a bottom plate 1, a material platform 2 is installed on one side of the top of the bottom plate 1, and a cleaning bracket 3 is symmetrically installed on one end of the top of the material platform 2. There is a slot 4 in the middle of the inner side of the bracket 3, and a limited card slot 5 is provided on both sides of the cleaning bracket 3, and a cleaning board 6 is embedded in the slot 4, and the bottom surface of the cleaning board 6 is equidistantly bonded There is a rubber cleaning sheet 7, a top plate 8 is installed on the top of the cleaning plate 6, fixing grooves 9 are provided on both sides of the cleaning plate 6, and fixing bolts are connected to the corresponding positions of the cleaning bracket 3 on both sides and the fixing groove 9 10.

[0027] The inside of the top surface o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap