Method for cleaning cover plate glass stirring rod

A cover glass and stirring rod technology, which is applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of reducing the incidence of streaks in glass products, the impact of glass liquid quality, and the wear of stirring rods, so as to reduce the occurrence of Probability, improvement of production quality, and the effect of increasing the viscosity of molten glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

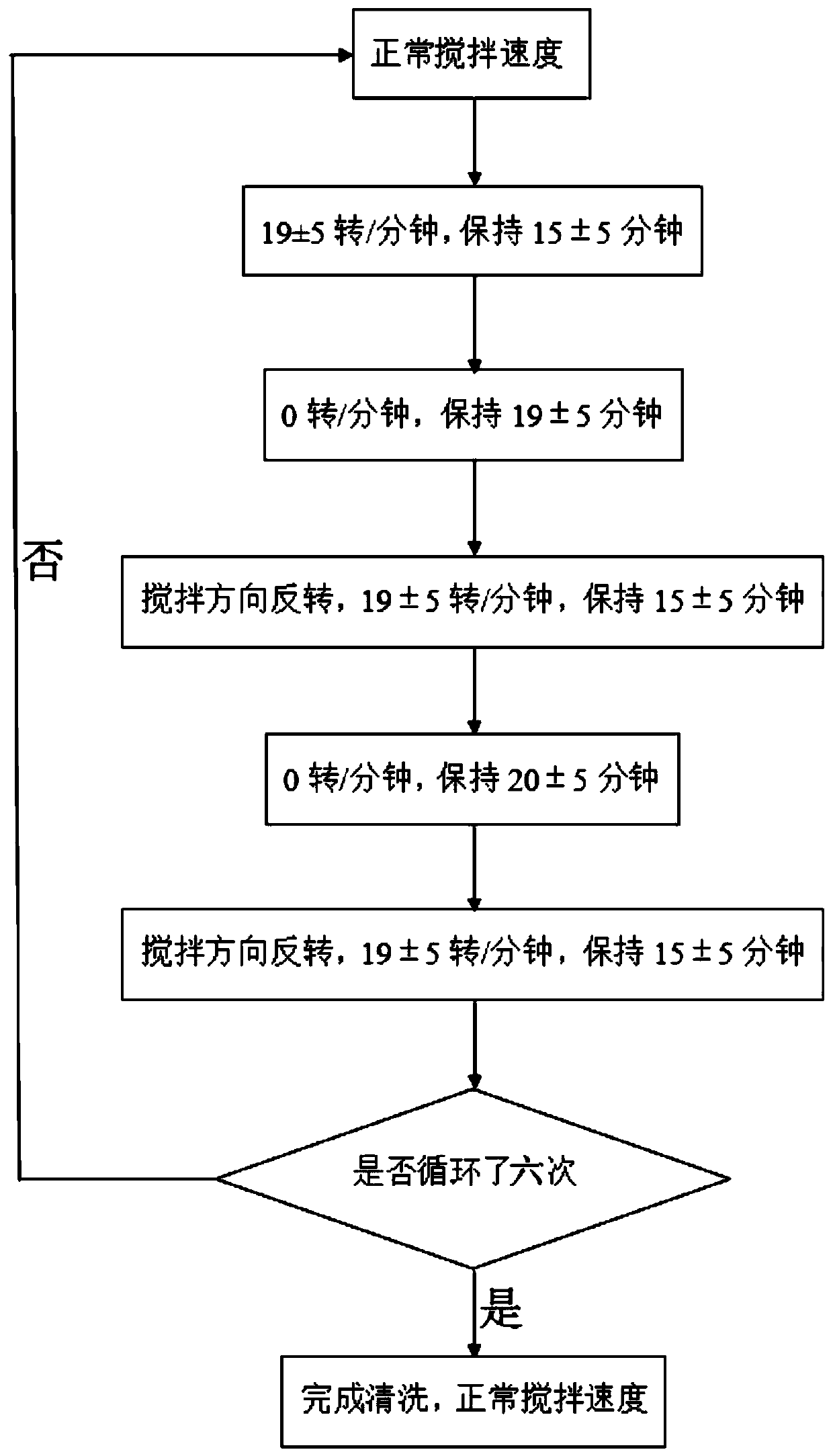

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

[0031] The cleaning of the stirring rod is divided into three aspects. First, it is necessary to confirm the safety margin of the process before cleaning, confirm whether the parameters are reasonable, and ensure the stability and control of the process. The second is the specific cleaning process. The third is to control the amount of glass liquid drawn out and the process temperature during the cleaning process of the stirring rod.

[0032] First of all, before the stirring rod is cleaned, the current in the heating section needs to be greater than 4500A and less than 5600A; the current in the clarification section needs to be greater than 4000A and less than 5000A; the current in the second section of clarification needs to be greater than 3000A and less than 4000A; 30kw; the power of the cooling section must be greater than 25kw; the power of the feed tank must be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com