Underground pipe gallery cast-in-situ aluminum film construction method

An underground pipe gallery and construction method technology, applied in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of less repeated use of existing formwork, difficult cast-in-place section walls, and heavy formwork weight, etc. Reduce production and processing steps, reduce construction noise, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

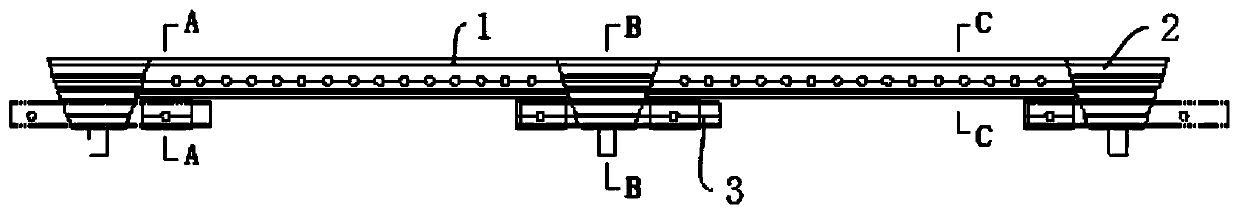

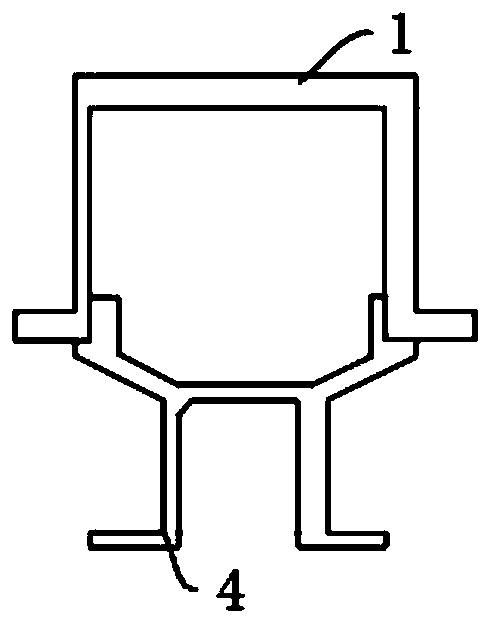

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

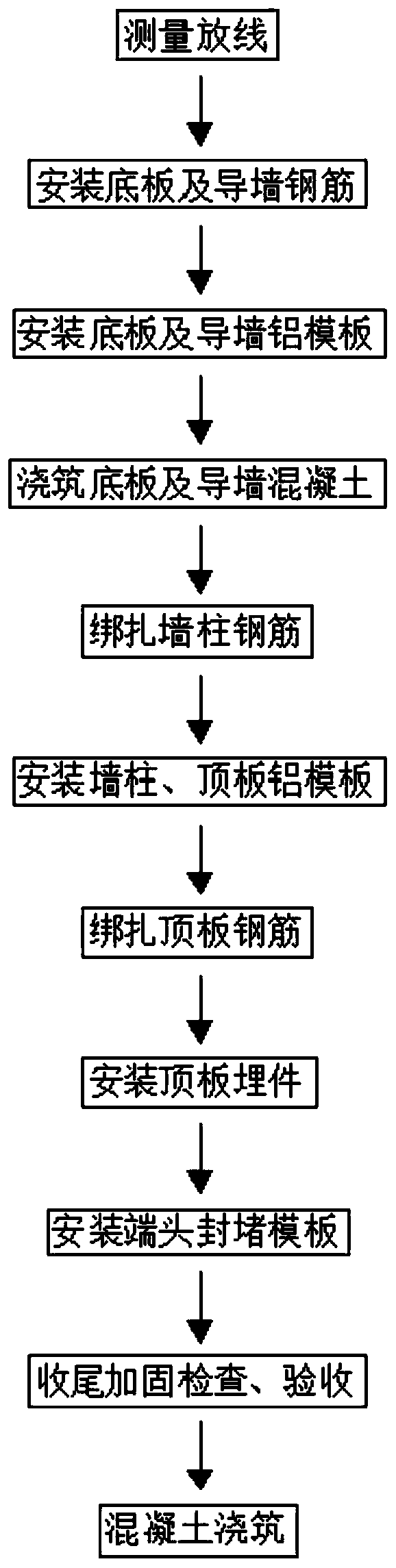

[0024] A construction method of cast-in-situ aluminum film for underground pipe gallery,

[0025] The first step, on-site preparation

[0026] (1) The foundation pit dewatering wells and drainage ditches at the construction site should be completed, and the dewatering elevation should meet the design requirements.

[0027] (2) The spray anchor on the side wall of the foundation pit reaches the design strength, the construction of the base concrete cushion is completed, the foundation elevation meets the design requirements, the construction of the base waterproof membrane and waterproof protective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com