Turnover type assembling and positioning device

An assembly positioning device, flip-type technology, applied in the direction of material gluing, connecting components, mechanical equipment, etc., can solve the problems of reducing production accuracy, low precision, and sticking of glue strips, etc., to improve stability, improve positioning accuracy, reduce The effect of bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

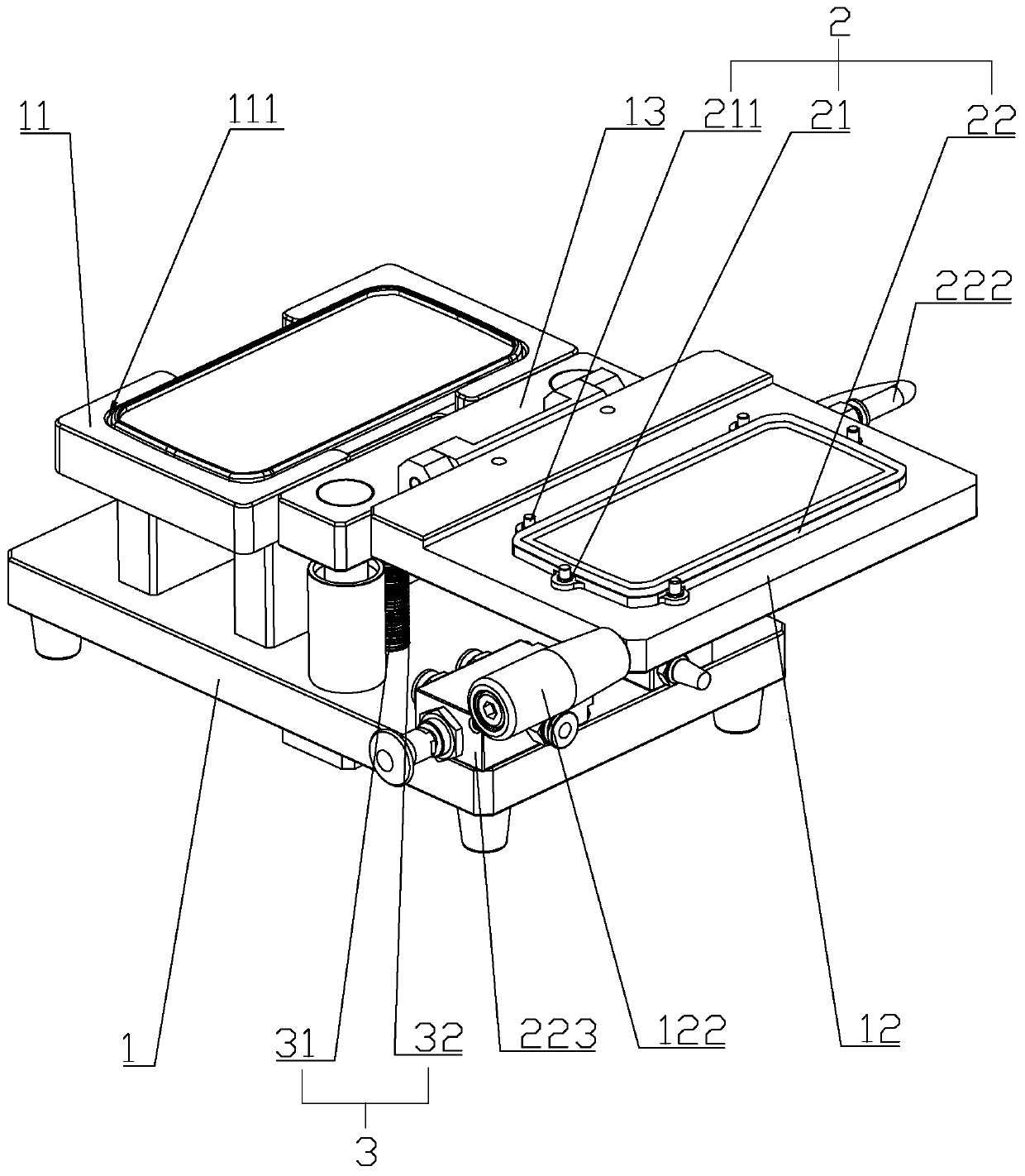

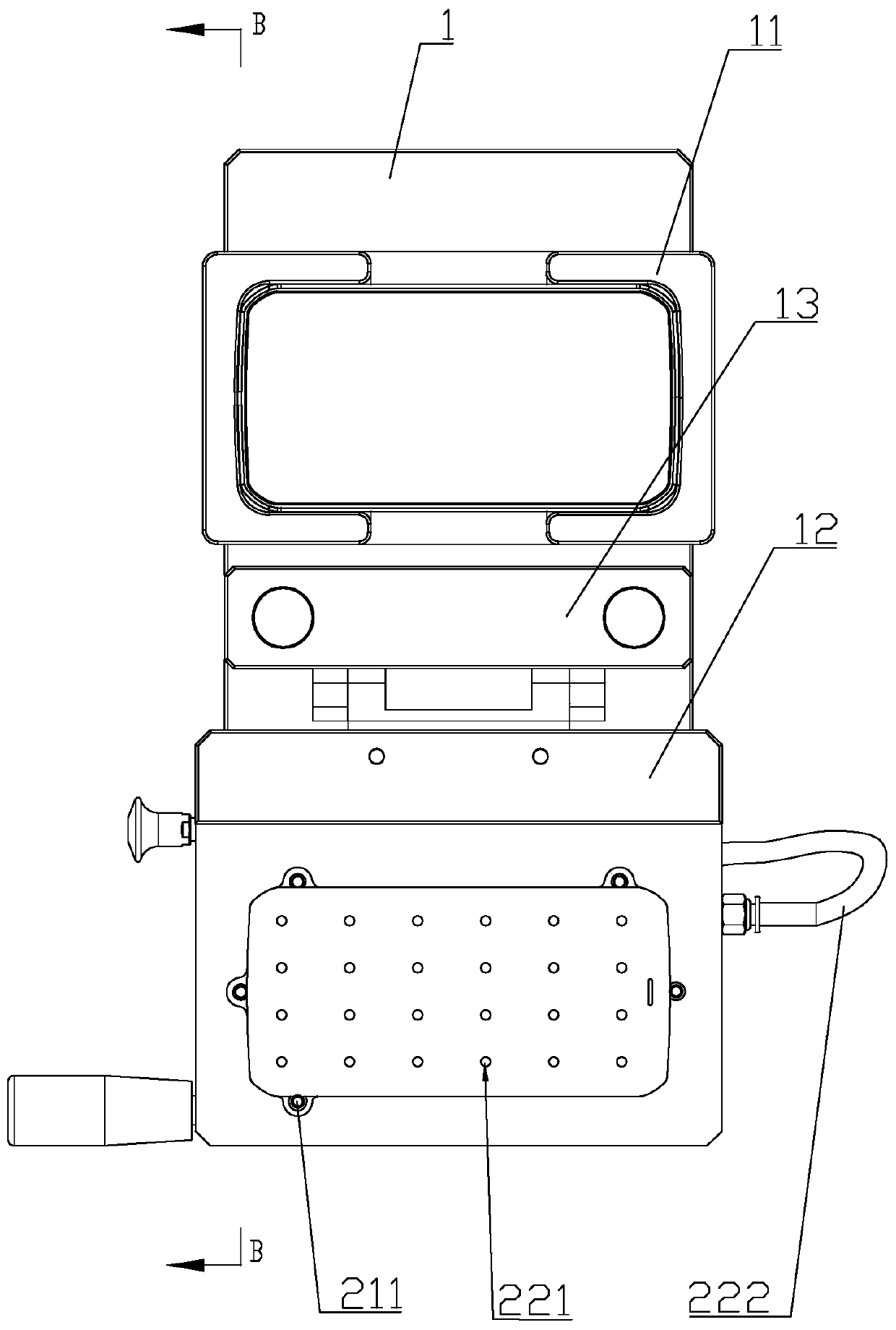

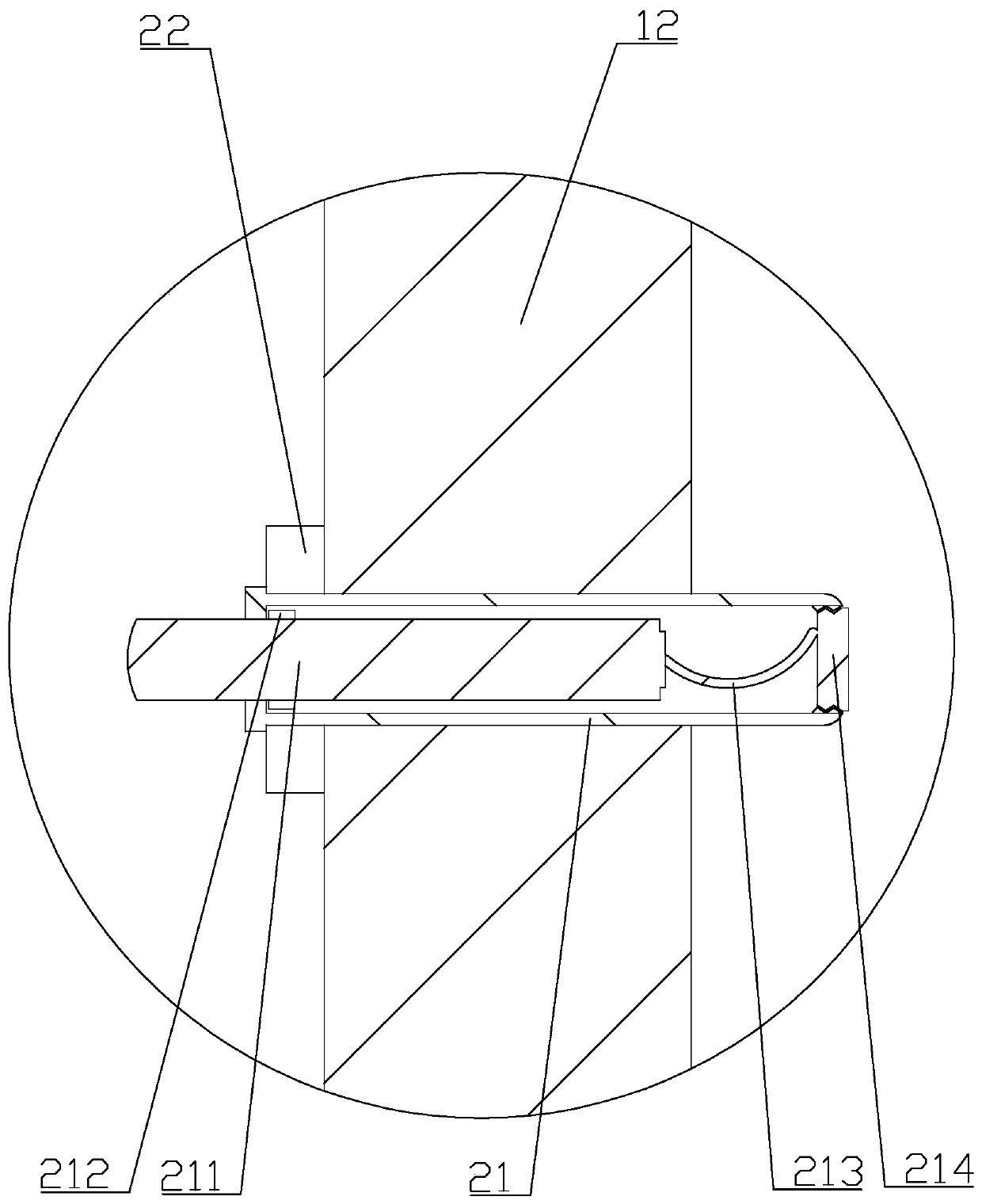

[0041] Embodiment one: refer to figure 1 , is a flip-type assembly and positioning device disclosed in the present invention, including a base 1, a positioning plate 11 arranged on the base 1 to carry the battery cover, a pressing plate 12 arranged on the positioning plate 11 for placing rubber strips, A locking device 2 arranged on the base 1 for attaching the adhesive strip to the pressing plate 12 and a driving device 3 arranged on the base 1 . The base 1 is in the shape of a cuboid, and the four corners of the base 1 are provided with four support feet in the shape of a circular platform. The support feet are made of rubber and fixed to the base 1 by screws to support the base 1 .

[0042] The base 1 and the positioning plate 11 are fixed by screws, and the positioning plate 11 and the base 1 are parallel to each other. The top of the positioning plate 11 is provided with a square positioning groove 111 for placing the battery cover. The positioning groove 111 is cross-sha...

Embodiment 2

[0051] Embodiment two: refer to Figure 5 , the difference from Embodiment 1 is that the driving member includes a servo motor 33 arranged on the base 1 and a screw 331 fixed coaxially with the output shaft of the servo motor 33, the servo motor 33 and the base 1 are fixed by screws, and the screw 331 is vertical Straight into the lifting plate 13 and screwed with the lifting plate 13.

[0052] The driving device 3 includes a gear 34 fixed coaxially with the pressing plate 12 , a rack 35 vertically arranged on the base 1 , and a switching mechanism 36 arranged on the base 1 to control the forward and reverse rotation of the servo motor 33 . The bottom end of the rack 35 is welded and fixed to the base 1 , and one side of the tooth groove is away from the positioning plate 11 . The gear teeth of the gear 34 are distributed on the side of the gear 34 away from the pressing plate 12, so that the rack 35 meshes with the gear 34 before the pressing plate 12 is overturned, and when...

Embodiment 3

[0058] Embodiment three: refer to Figure 7, and the difference with Embodiment 2 is that: since the pressing plate 12 is easy to collide with the lifting plate 13 after acceleration, it is easy to cause the adhesive strip film adsorbed on the pressing plate 12 to fall due to inertia and vibration, so the positioning plate 11 Set the cushioning component 4. The buffer assembly 4 includes a pin shaft 41 disposed on the pressing plate 12 and a piston 42 disposed on the end of the pin shaft 41 away from the pressing plate 12 .

[0059] The lifting plate 13 is provided with an air storage tank 132 , the air storage tank 132 is square, and the bottom wall of the air storage tank 132 is provided with an air hole 133 passing through the lifting plate 13 and communicating with the outside. The piston 42 is made of rubber and when the pressing plate 12 is overturned, the piston 42 is plugged with the air storage tank 132. Since the overturning path of the pressing plate 12 is arc-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com