Steel ball spacer ring of linear transmission device

A technology of linear transmission and spacer rings, which is applied to transmission devices, belts/chains/gears, mechanical equipment, etc., and can solve problems such as increased material costs, unfixable spacing, and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

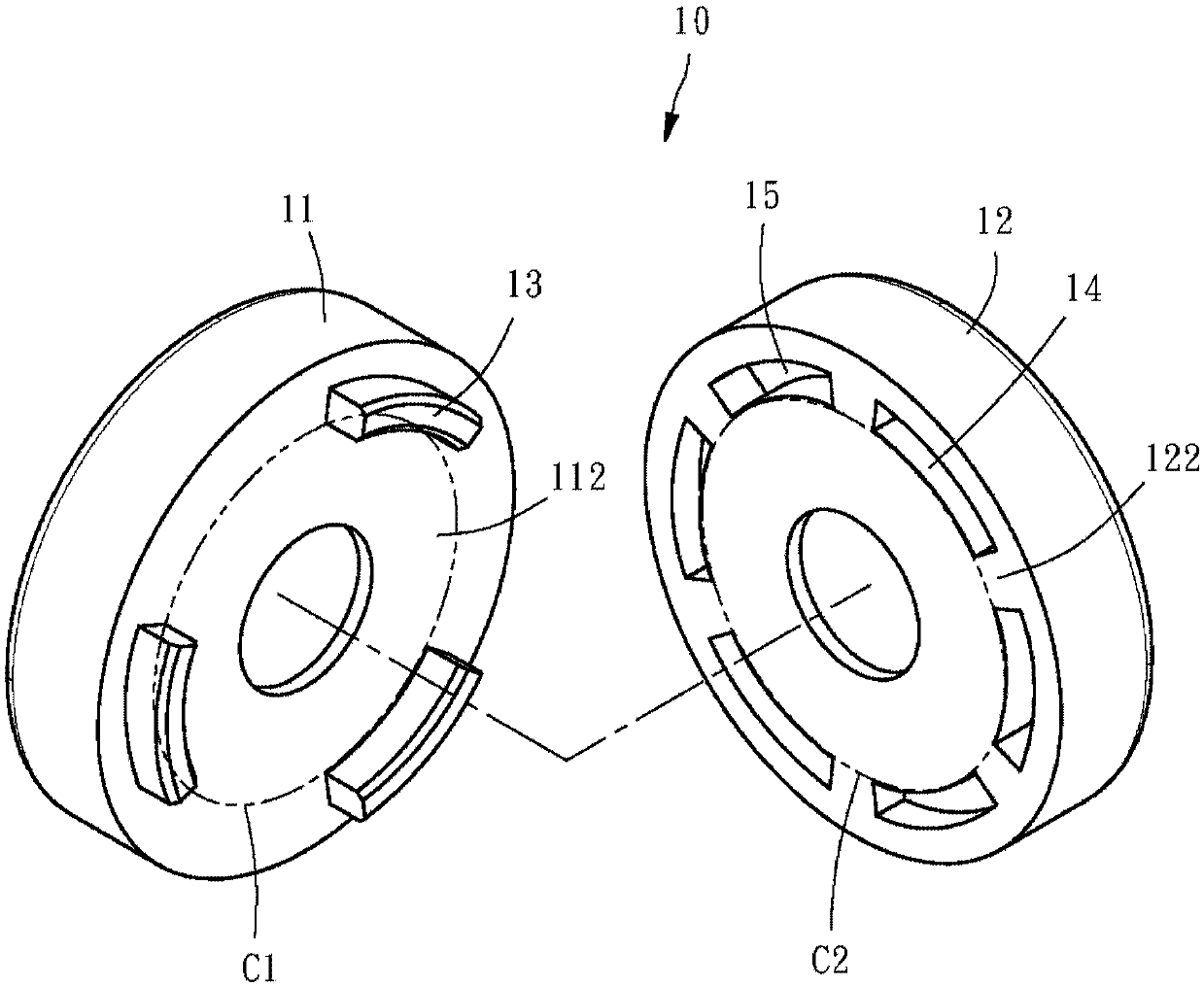

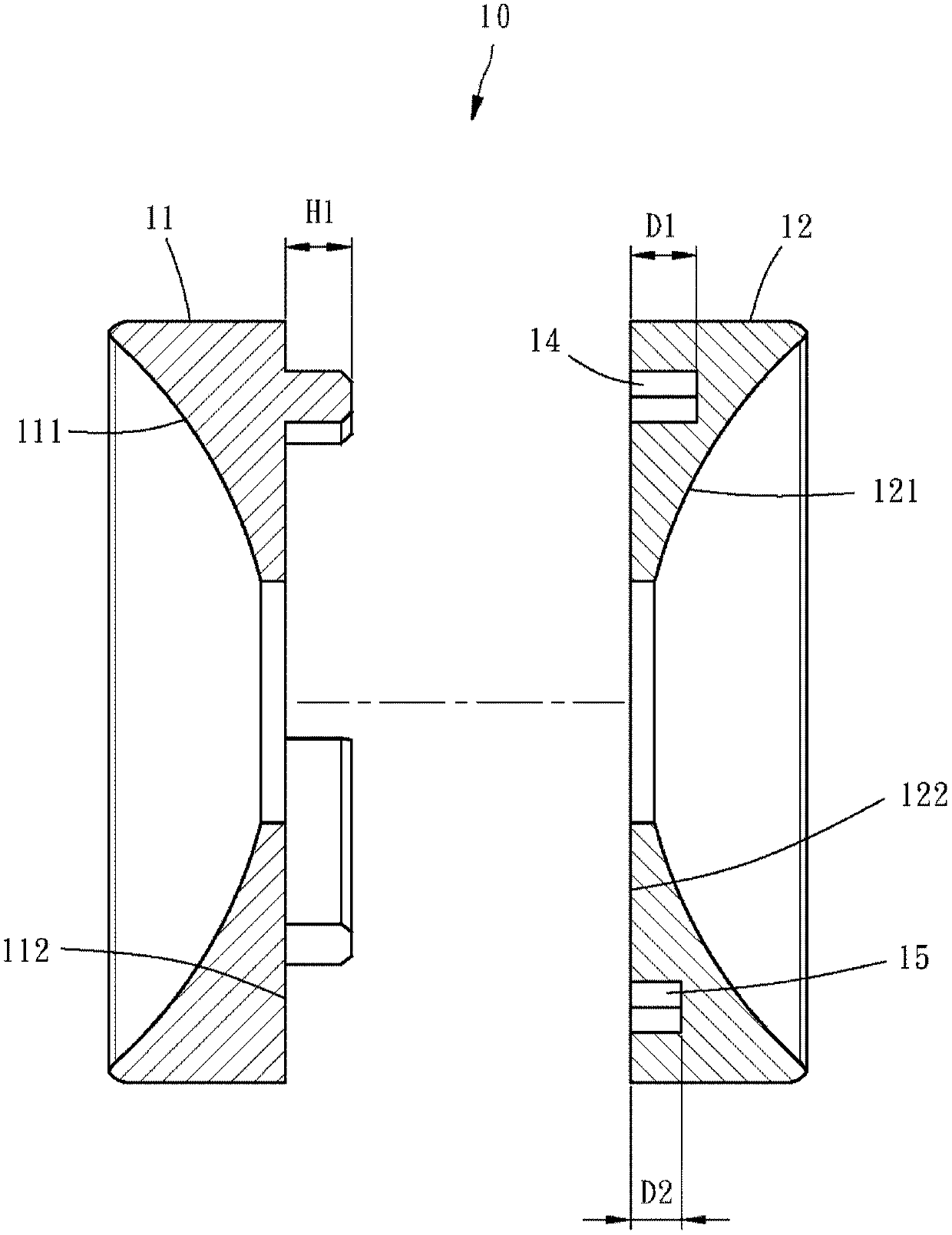

[0035] In order to describe the structure and features of the present invention in detail, the following preferred embodiments are now described with accompanying drawings as follows:

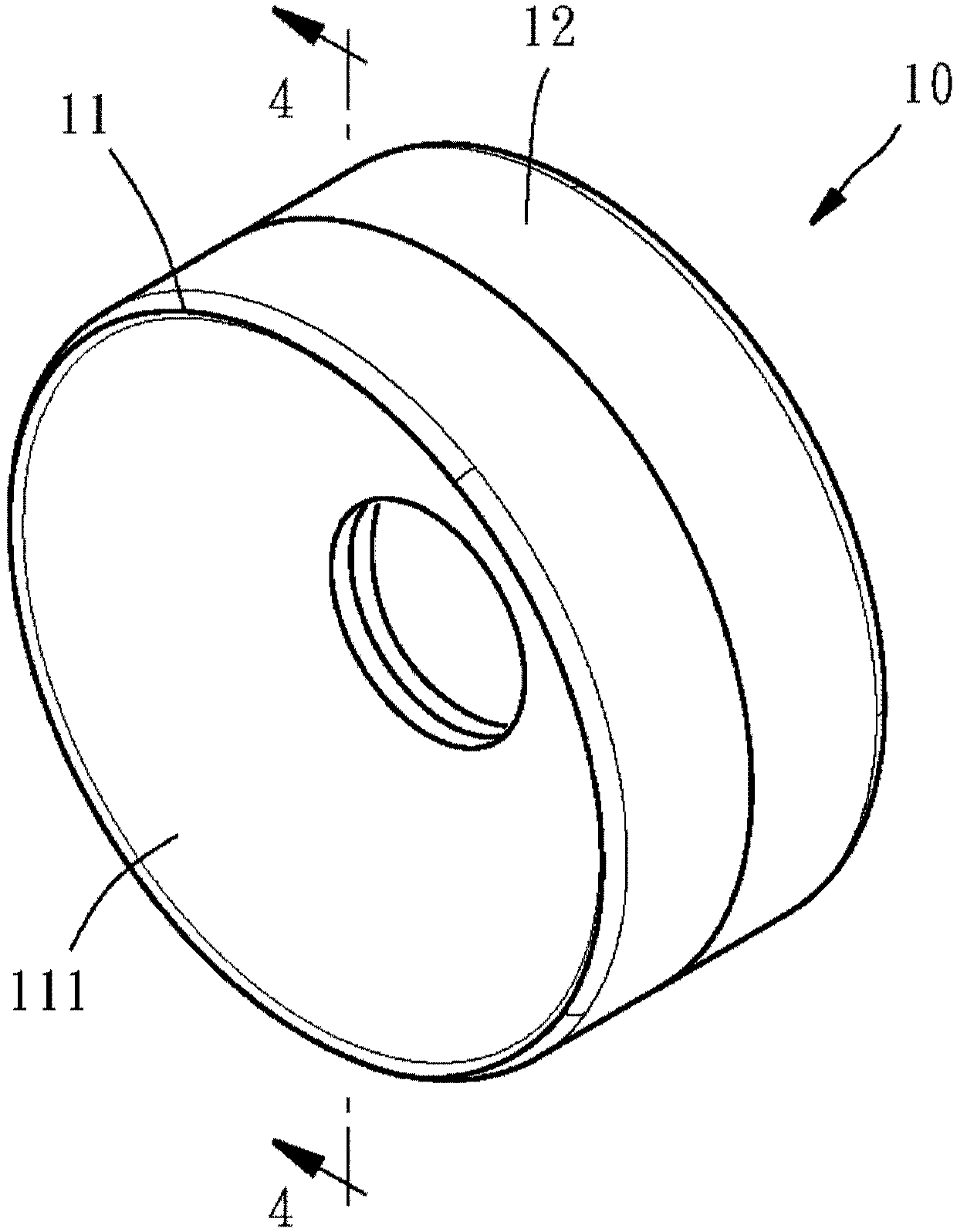

[0036] refer to Figure 9 , a steel ball spacer ring 10 of a linear transmission device in the present invention is used to be placed in the circulation path 100 of the linear transmission device and between two rolling elements 200, so that the circulation path 100 is filled, and the Linear actuators can be ball screws, bearings, linear slides, roller screws, etc. The embodiment of the present invention is illustrated by using a general ball screw. The ball screw of the aforementioned linear transmission device includes a long shaft and a moving body that can slide on the long shaft. The long shaft and the moving body belong to the prior art and are not The main technical features of the present invention will not be repeated here, nor shown on the drawings. The rolling elements 200 are steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com