Heating assembly

A technology of heating components and electric heating wires, which is applied in the field of machinery and electricity, can solve the problems of low heat generation efficiency of electric heating wires, high-temperature radiation damage of equipment shells, etc., and achieve the effect of increasing the layout length, reducing heat radiation, and increasing heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

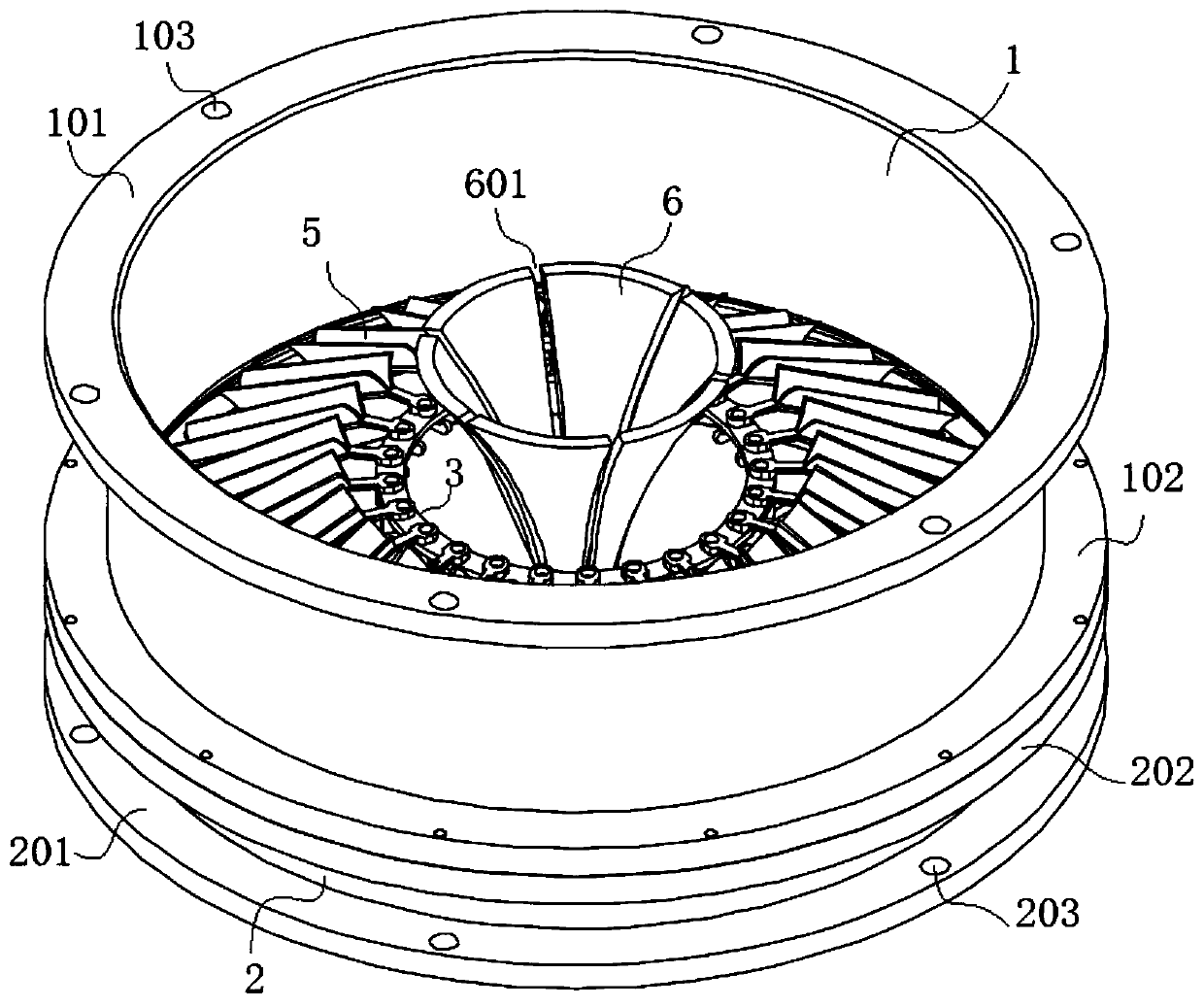

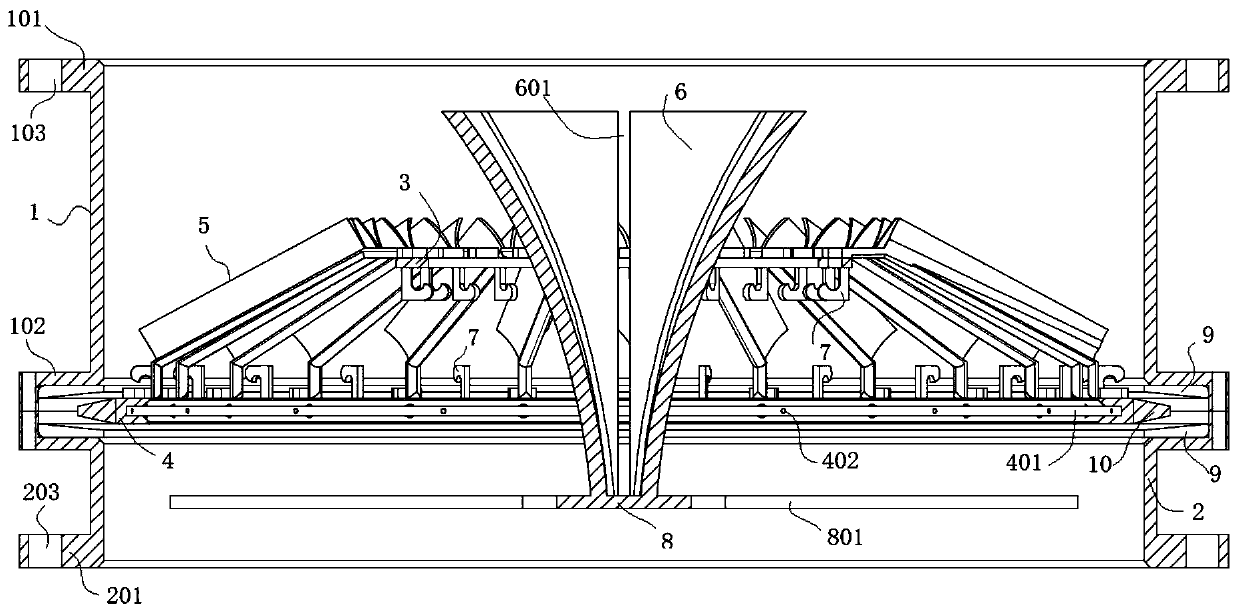

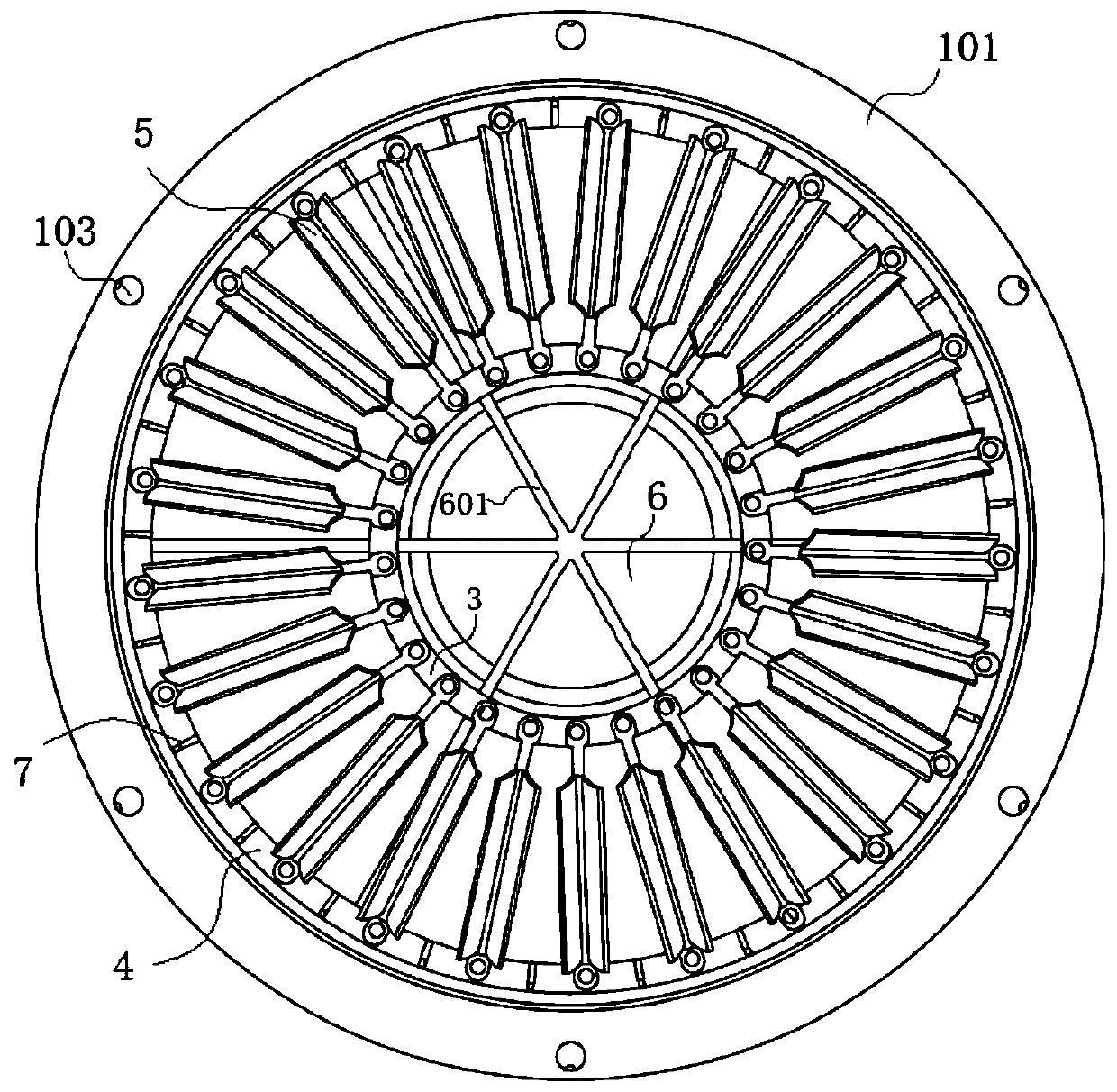

[0045] see Figure 1-3 As shown, the present invention is a heating assembly, including a first shell 1, an electric heating wire and a second shell 2, both of which are cylindrical structures.

[0046] One end surface of the first housing 1 is provided with a first ring plate 101, and the opposite end surface of the first housing 1 is provided with a second ring plate 102; wherein, the end surface of the second ring plate 102 is provided with a first notch along the annular direction 105, the first notch 105 communicates with the inner cavity of the first housing 1; a magnetic ring 9 is fitted in the first notch 105;

[0047] One end surface of the second housing 2 is provided with a third ring plate 202, and the opposite end surface of the second housing 2 is provided with a fourth ring plate 201; wherein, the end surface of the third ring plate 202 is provided with a second notch along the annular direction 204, the second notch 204 communicates with the inner cavity of th...

Embodiment 2

[0060] Based on the heating assembly described in Embodiment 1, the air supply assembly can be used at one end of the second housing 2 to heat the incoming air, and heat energy can be obtained through the output hot air flow.

[0061] In addition, in terms of increasing the heating power, the heating power can be increased by sequentially stacking and designing multiple heating components described in the first embodiment.

[0062] For the heating assembly in the first embodiment, the constituent materials are high-temperature-resistant, heat-insulating materials, and have insulating effect, such as mica.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com