Pressure chamber for gas seepage test of coal rock samples

A pressure chamber and coal-rock sample technology, applied in the field of coal-rock sample gas seepage test equipment, can solve problems such as the inability to truly simulate the real underground conditions of coal-rock samples and the limited test conditions of the specimen box, and achieve high practical guiding significance and reliability. Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

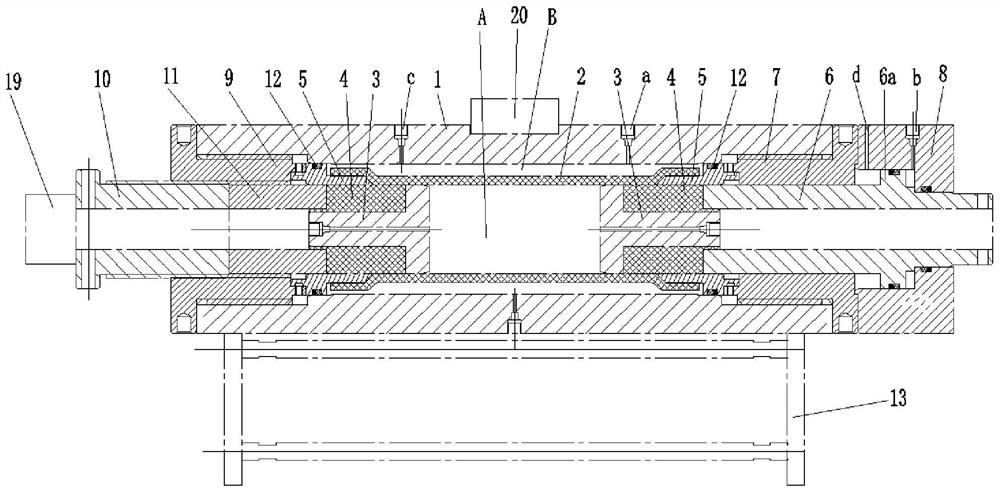

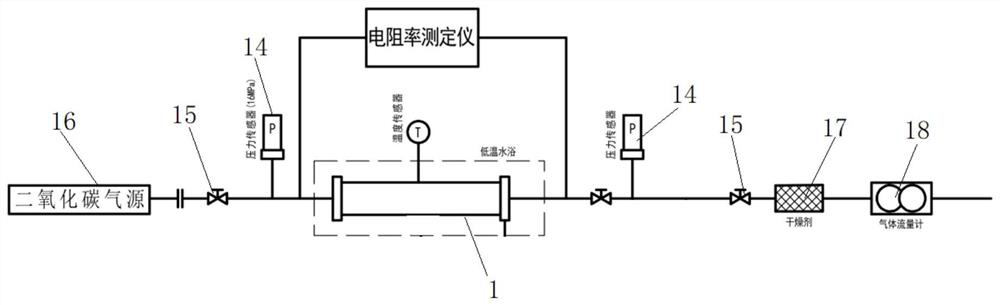

[0013] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0014] combine figure 1 , figure 2 As shown, a pressure chamber for coal-rock sample gas seepage test is mainly composed of a round steel cylinder 1, a circumferential pressure transmission sleeve 2, a T-shaped head 3, a PEEK sleeve 4, a conical steel sleeve 5, a right piston sleeve 6, Right first pressure sleeve 7, right second pressure sleeve 8, left first pressure sleeve 9, left second pressure sleeve 10, ring pad 11, sealing retaining ring 12, support foot 13, pressure sensor 14, high pressure valve 15, A carbon dioxide gas source 16, a desiccant 17, a gas flow meter 18, a vibrator 19, and an ultrasonic generator 20 are composed.

[0015] The annular pressure transmission sleeve 2 is placed in the round steel cylinder 1 , and the outer diameter of the annular pressure transmission sleeve 2 is smaller than the inner diameter of the round steel cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com