Pipeline circumferential ultrasonic flaw detection device

A flaw detection device and ultrasonic technology, applied in the field of detection, can solve the problems of labor and time, low precision, etc., and achieve the effect of improving the scope of application and improving the detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

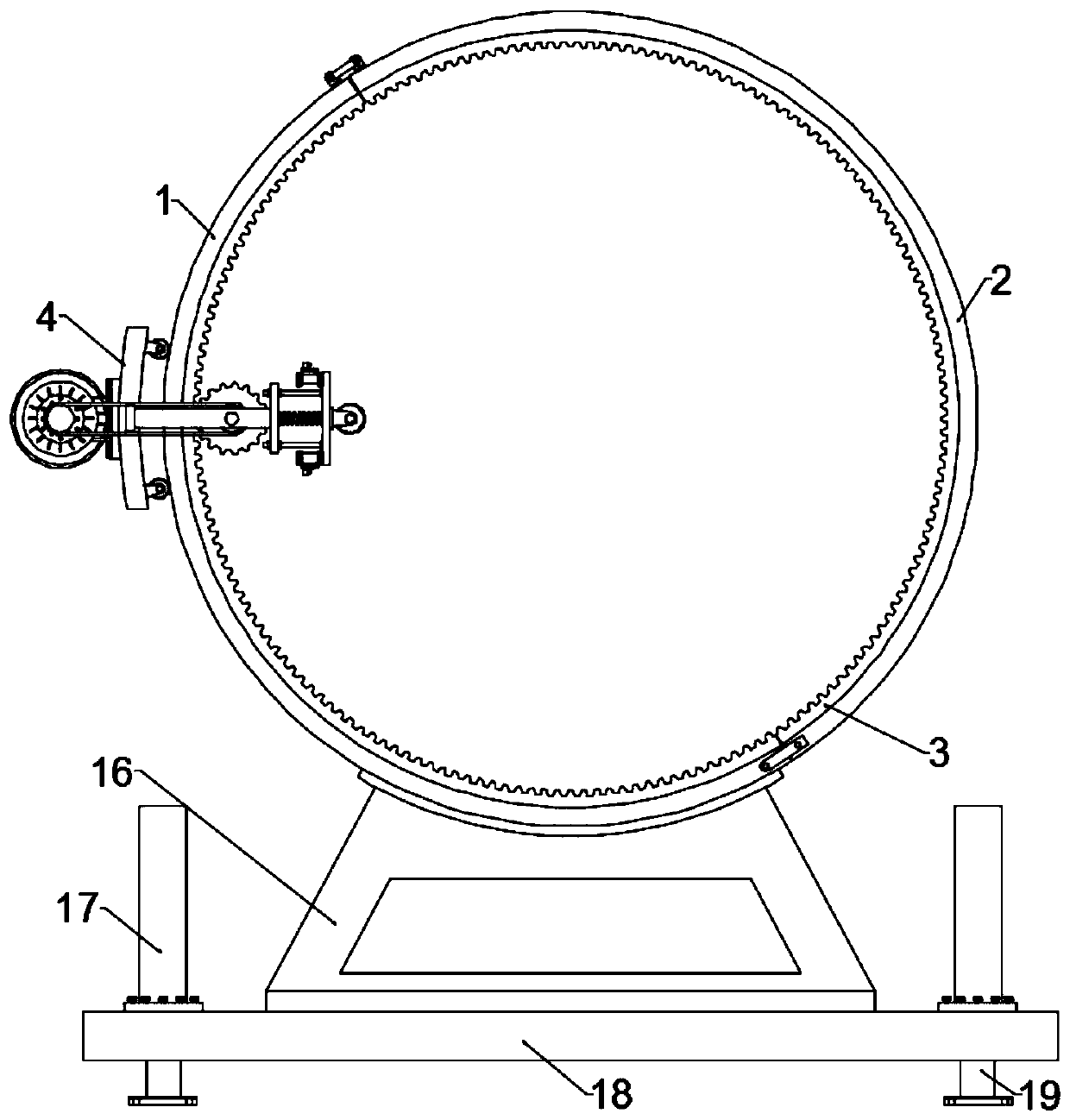

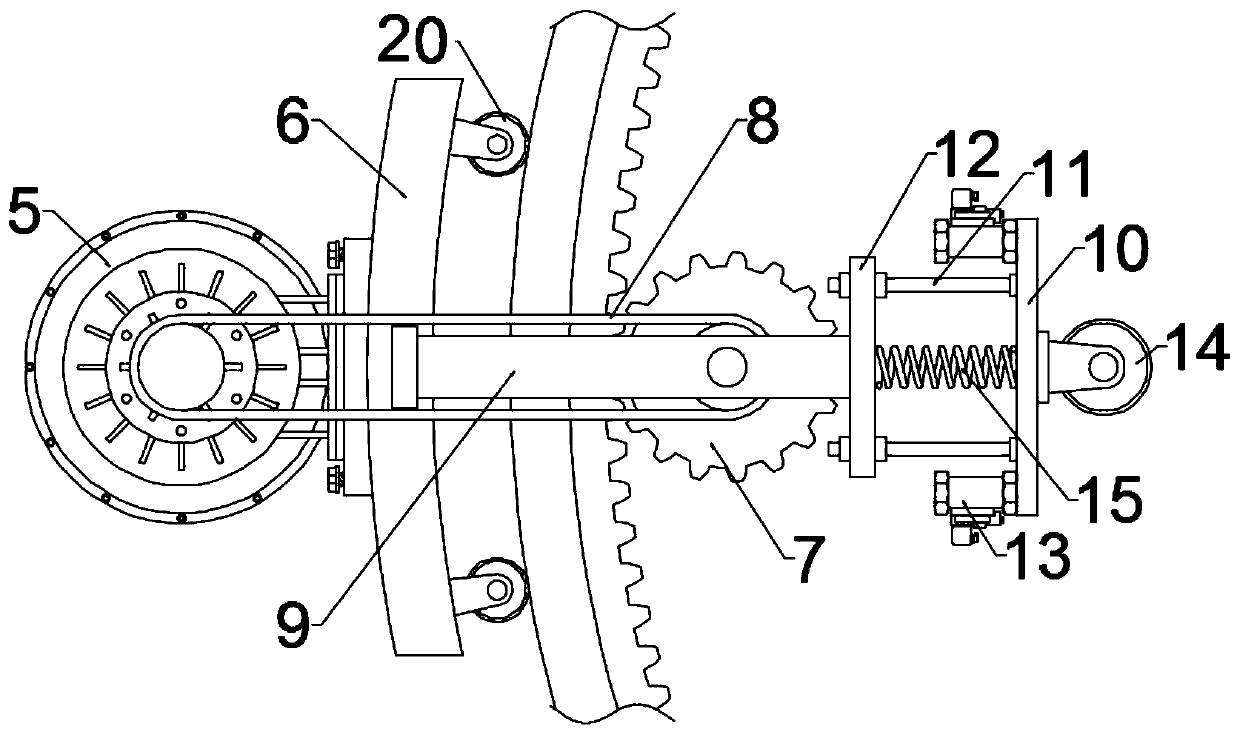

[0021] see Figure 1~3 , in an embodiment of the present invention, a pipeline circumferential ultrasonic flaw detection device includes a first ring body 1, a second ring body 2, a detection mechanism arranged on the first ring body 1 and the second ring body 2, and the detection mechanism is directed to Matched semicircular inner rack 3 and base 18;

[0022] Wherein, the inner walls of the first ring body 1 and the second ring body 2 are fixed with a semicircular inner rack 3, the upper ends of the first ring body 1 and the second ring body 2 are hinged, and the first ring body 1 and the second ring body The lower ends of the two rings 2 are connected by locks. After the locks are opened, the hinged first ring 1 and the second ring 2 can be opened, so that they can be sleeved on the outer wall of the pipeline. What needs to be explained Yes, a complete circle is formed between the first ring body 1 and the second ring body 2 after the lock is locked.

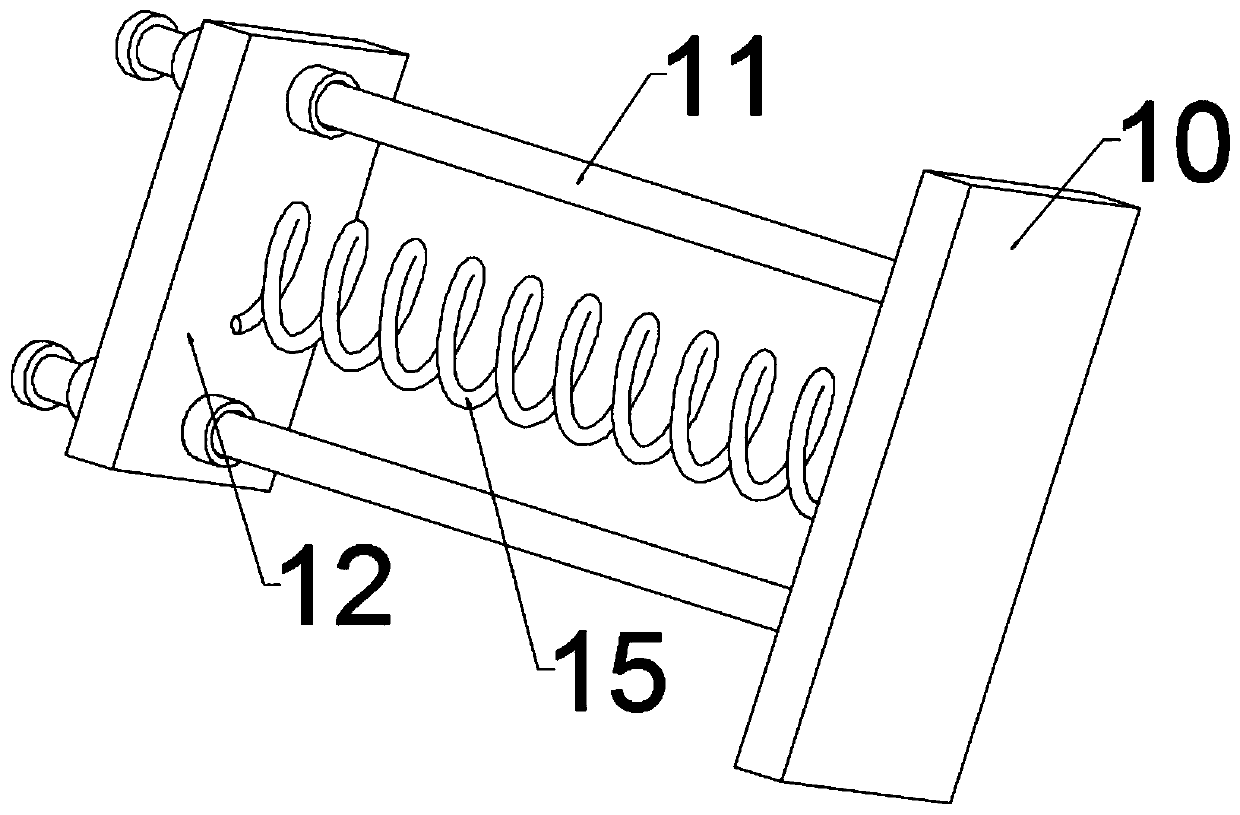

[0023] Specifically,...

Embodiment 2

[0028] In order to further explain the above-mentioned pipeline circumferential ultrasonic flaw detection device, in another embodiment of the present invention, a pipeline circumferential ultrasonic flaw detection device, the lower part of the first ring body 1 is fixedly connected to the support frame 16, and the support frame 16 is fixed on the base 18 Above, the first ring body 1 is fixed by the support frame 16 and the fixing seat 18 to maintain overall stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com