A Mechanism for Tightening the Surface of a Film Disk

A technology of thin film and disk surface, applied in the field of thin film mirror equipment, can solve the problems of low production efficiency, uneven photoresist surface, increased production cost and production time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the scope of protection of the present invention is not limited to the following embodiments.

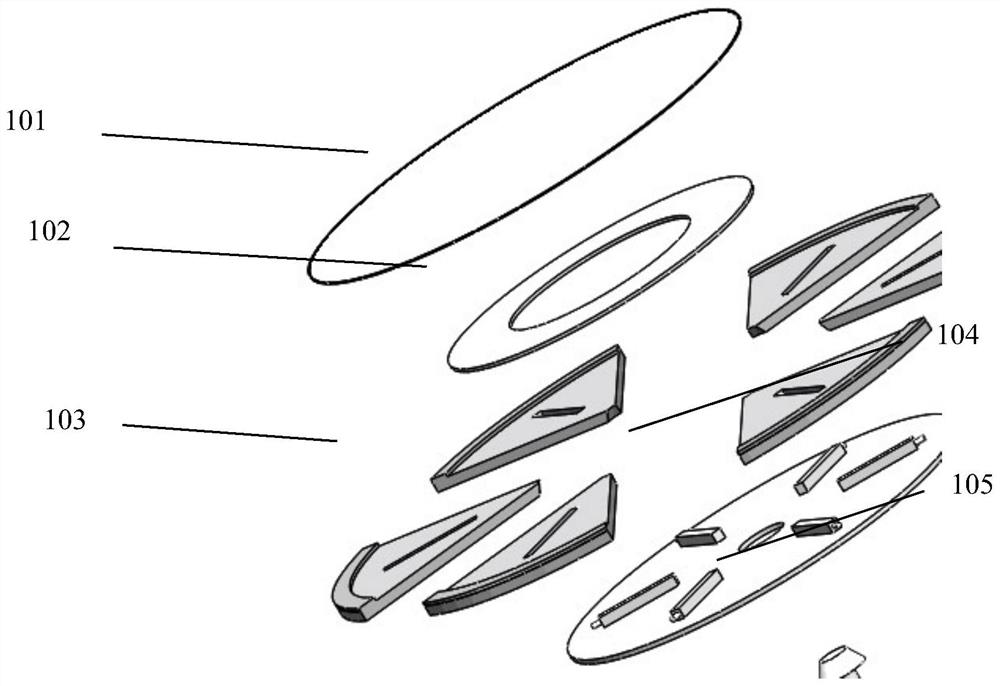

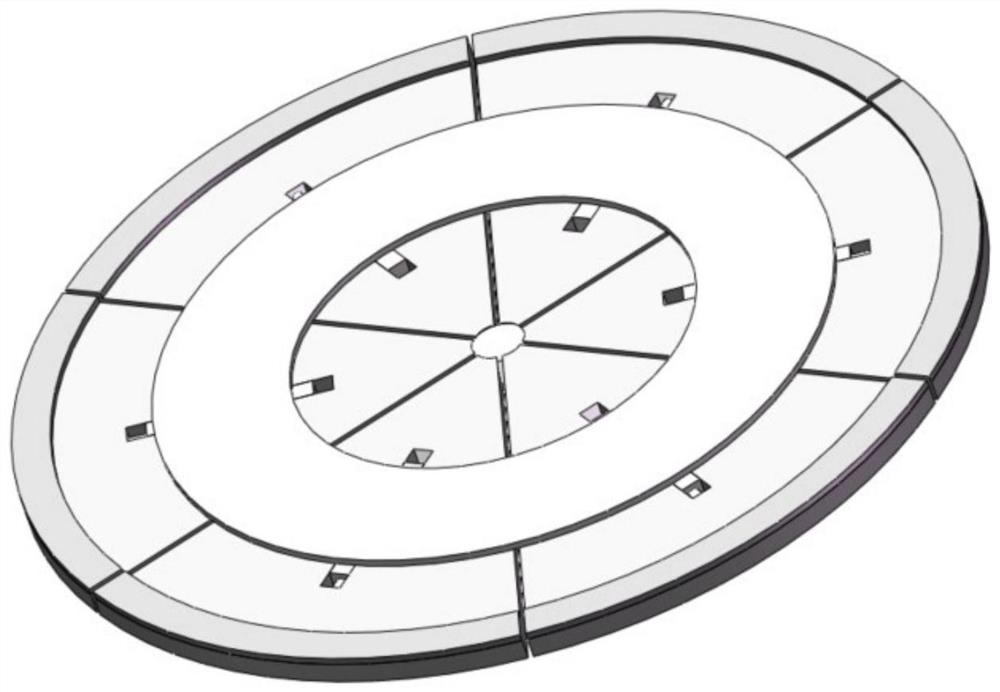

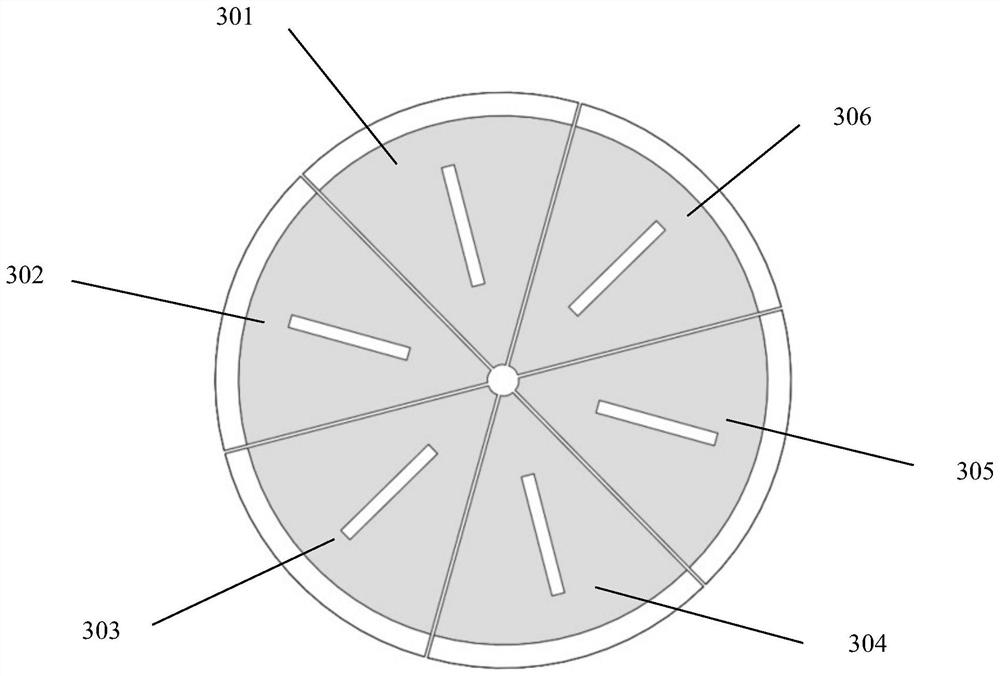

[0021] like Figure 1~5 As shown, in the initial state, the elastic cylinder (402) exerts a preload on the pie plate (103) to ensure that all fan-shaped grooves are at zero and have no displacement, and the film (101) is pasted on the film Glue on the boss area (402).

[0022] like Figure 1~5 As shown, when the mechanism is working, the upper cover (102) and the lower tray (104) are in a fixed state. Since the upper cover (102) and the lower tray (104) limit the axial freedom of the sectors (301, 302, 303, 304, 305, 306), the guide chute (402) slide block (401) Cooperate with limiting the degree of freedom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com