A digging method of a portable variable-diameter surround digging machine

A portable, pit-digger technology, applied in planting methods, excavation/covering of trenches, agriculture, etc., can solve the problems of exposed and excavated tree pits that are not standardized, and low pit-digging efficiency, so as to improve planting quality and reduce Operation cost, effect of preventing earthwork from being scattered everywhere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make those skilled in the art better understand the technical scheme of the present invention, the present invention will be further described below in conjunction with embodiment:

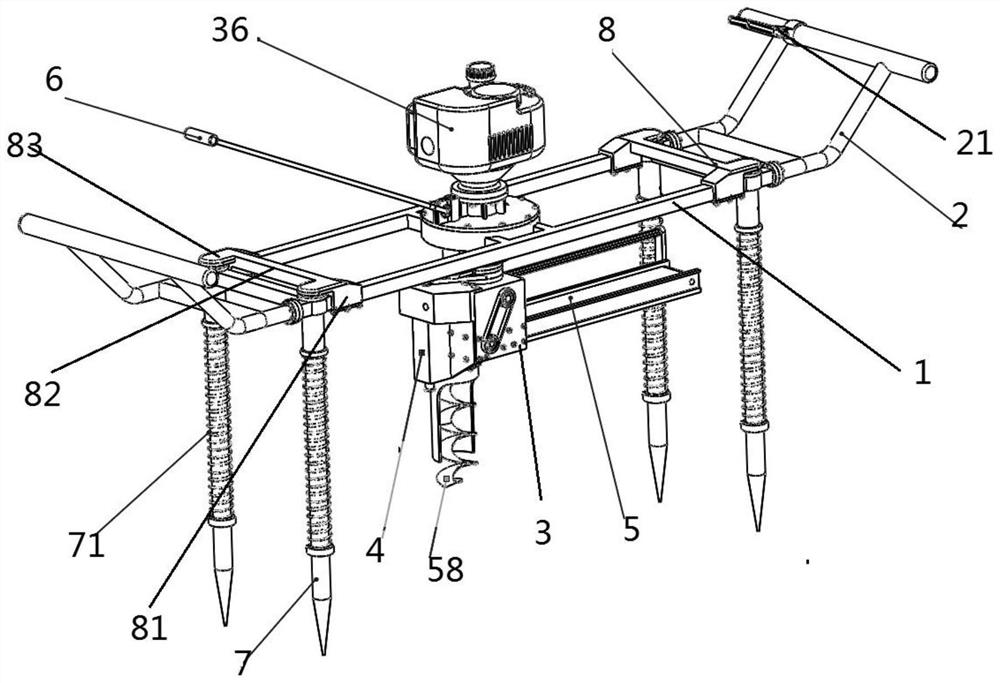

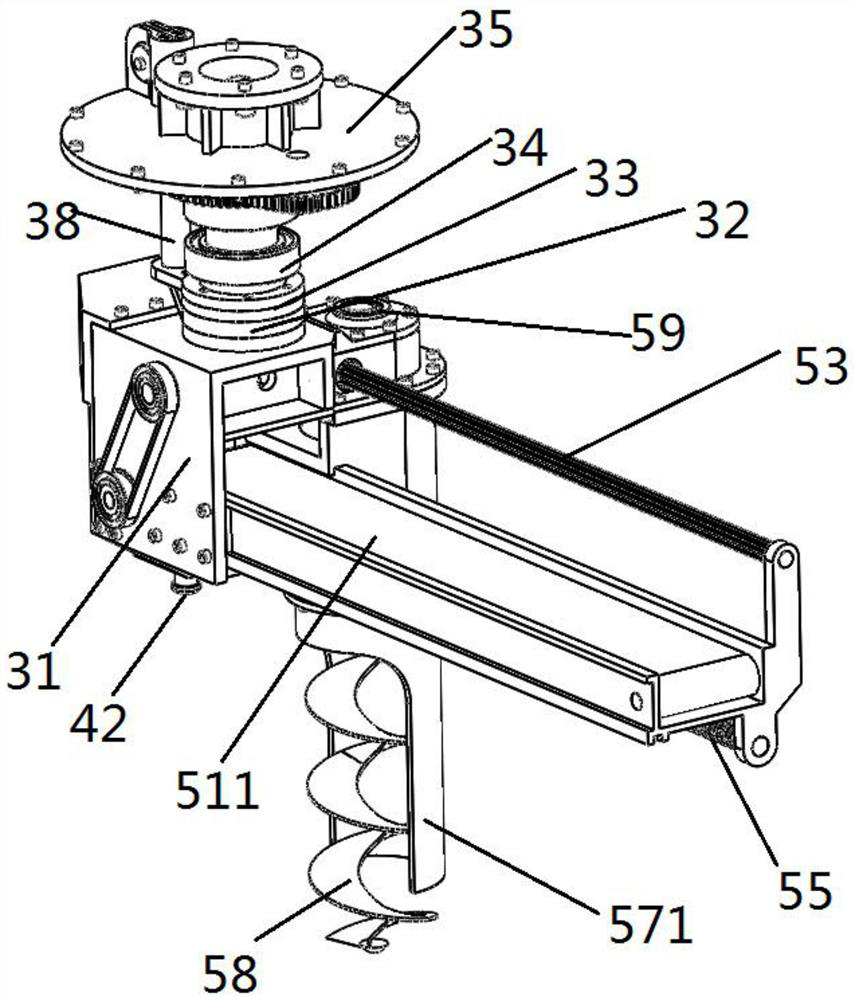

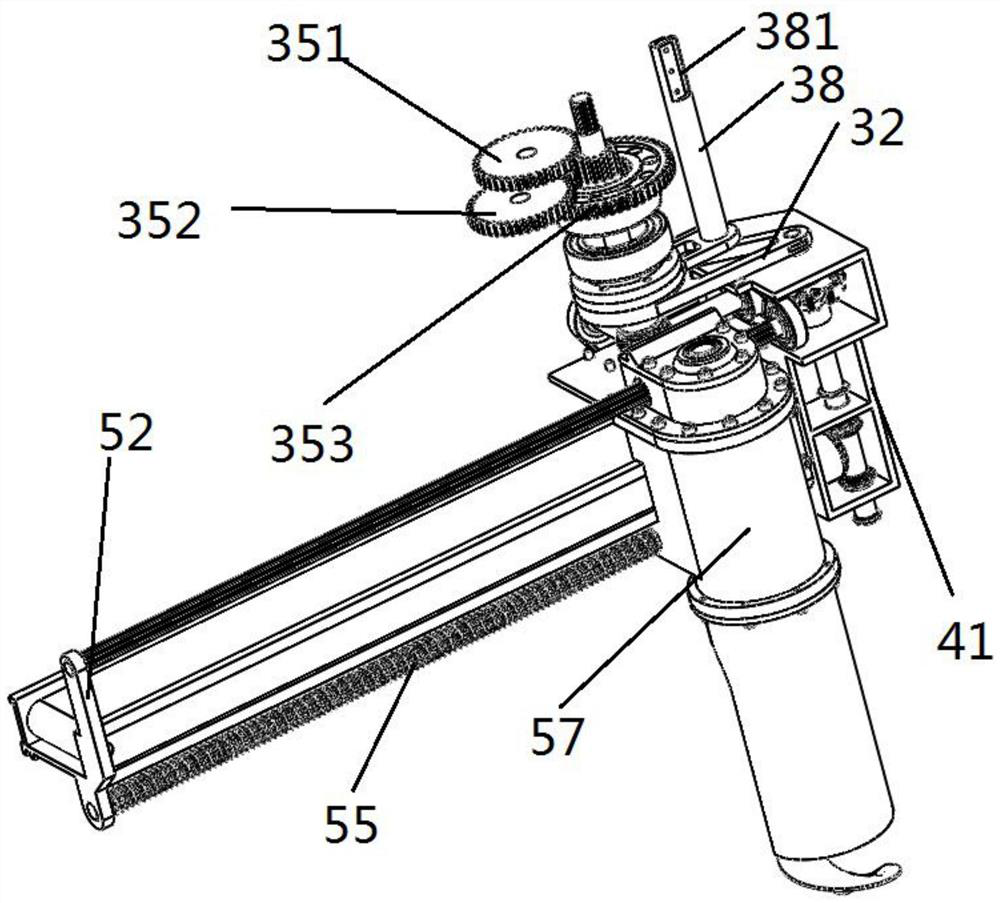

[0021] A portable variable-diameter surrounding digging method for a digging machine, including a support frame 1, the two ends of the support frame 1 are respectively connected to working handles 2, and the middle part of the support frame 1 is equipped with a speed-changing and diameter-changing mechanism 3 The two sides of the bottom of the speed-changing and diameter-changing mechanism 3 are respectively connected with a power distribution mechanism 4 and a direction-changing conveying mechanism 5, and the speed-changing and diameter-changing mechanism 3 is connected with a diameter-changing gear rod 6, and the four corners of the support frame 1 are respectively movable. It is connected with a fixed pin 7 perpendicular to the support frame. The speed change mechanism 3 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com