Tool heads for presses

A tool head and press technology, used in the plastic deformation of joints, the tool head of pipe presses, and the field of presses, can solve the problem that the tool head is bulky, unsuitable or only limitedly applicable, cannot be ideally clamped, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

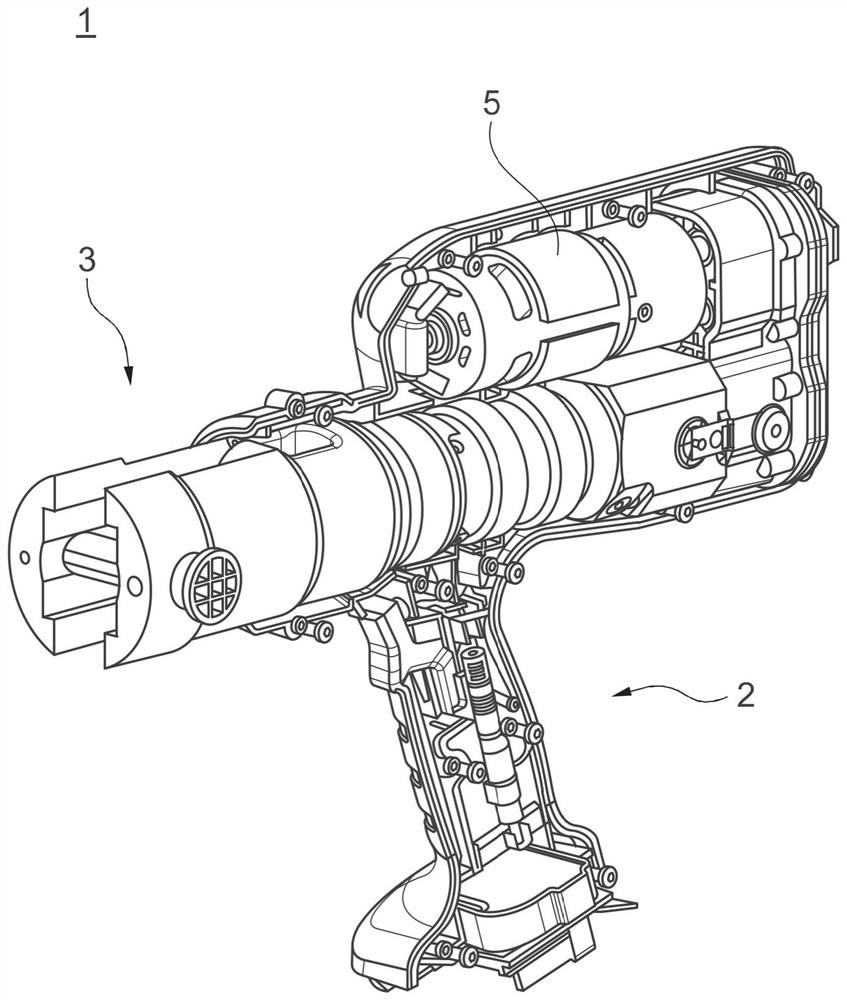

[0056] figure 1 A press 1 is shown in , which includes a handle 2 which can be manually guided by an operator or user. The tool bit 10 can be detachably coupled to the press 1 by means of the tool bit receptacle 3 .

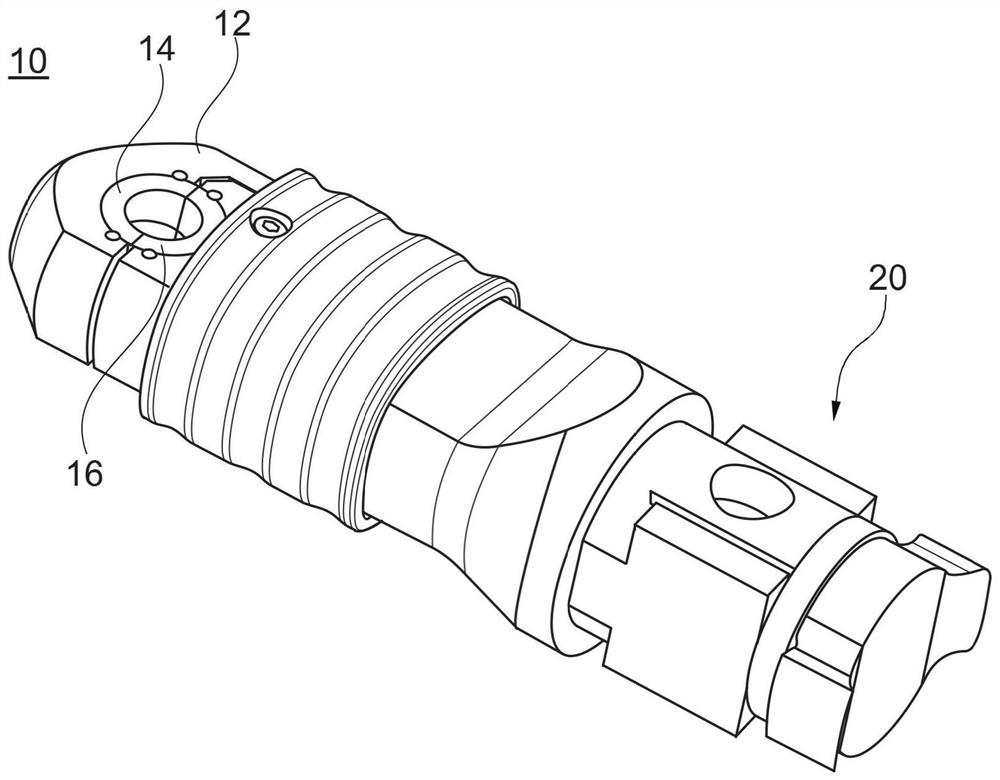

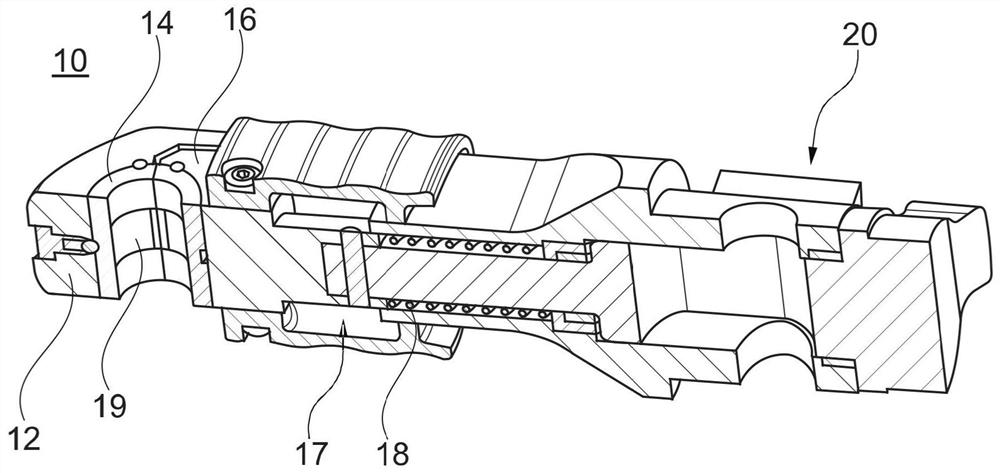

[0057] The press 1 also includes a drive 5 . The drive 5 can be an electric motor with a transmission, which drives the tool bit 10 via the tool bit receptacle 3 and thus can move the linearly movable press jaw 16 in order to plastically deform the workpiece. To deform the joint, the operator can actuate the corresponding joystick. By manipulating the joystick, the linearly movable pliers 16 of the tool head 10 first move from the stationary pliers 14 (see Figure 2A ) movement away. The workpiece or joint can then be clamped. The movable clamp 16 can then be pretensioned relative to the clamped joint, and by (re)actuating the joystick a force can be applied to the joint by means of the drive 5 via the clamp 14, 16 in order to plasticize the joint. out of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com