Circulation feeding equipment with powder recovery function

A technology of feeding equipment and powder, which is applied in processing and recycling, metal processing equipment, manufacturing tools, etc., can solve the problems of powder quality reduction, powder easy to raise dust, and pollute the environment, so as to achieve a high degree of automation and avoid excessive surplus materials , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

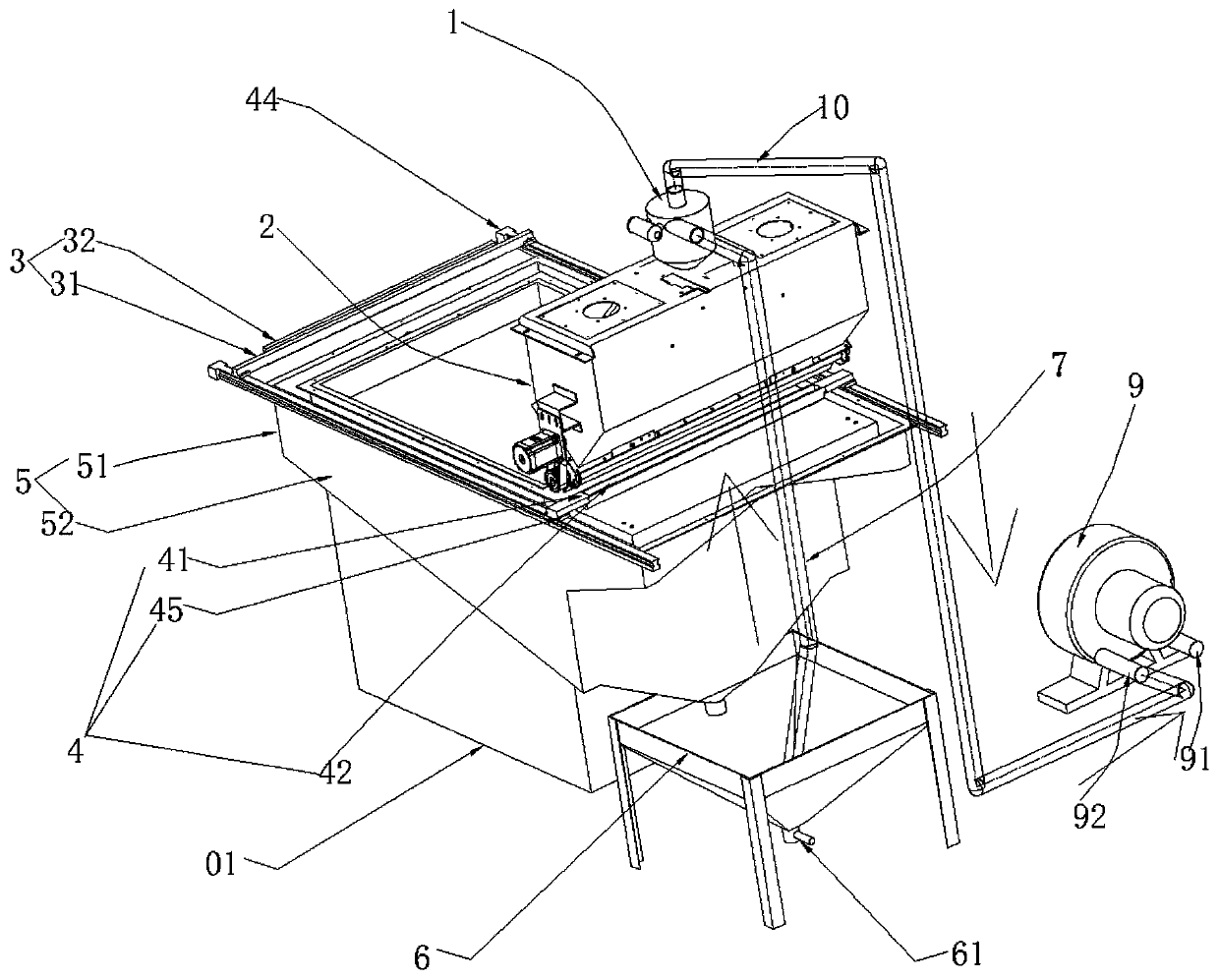

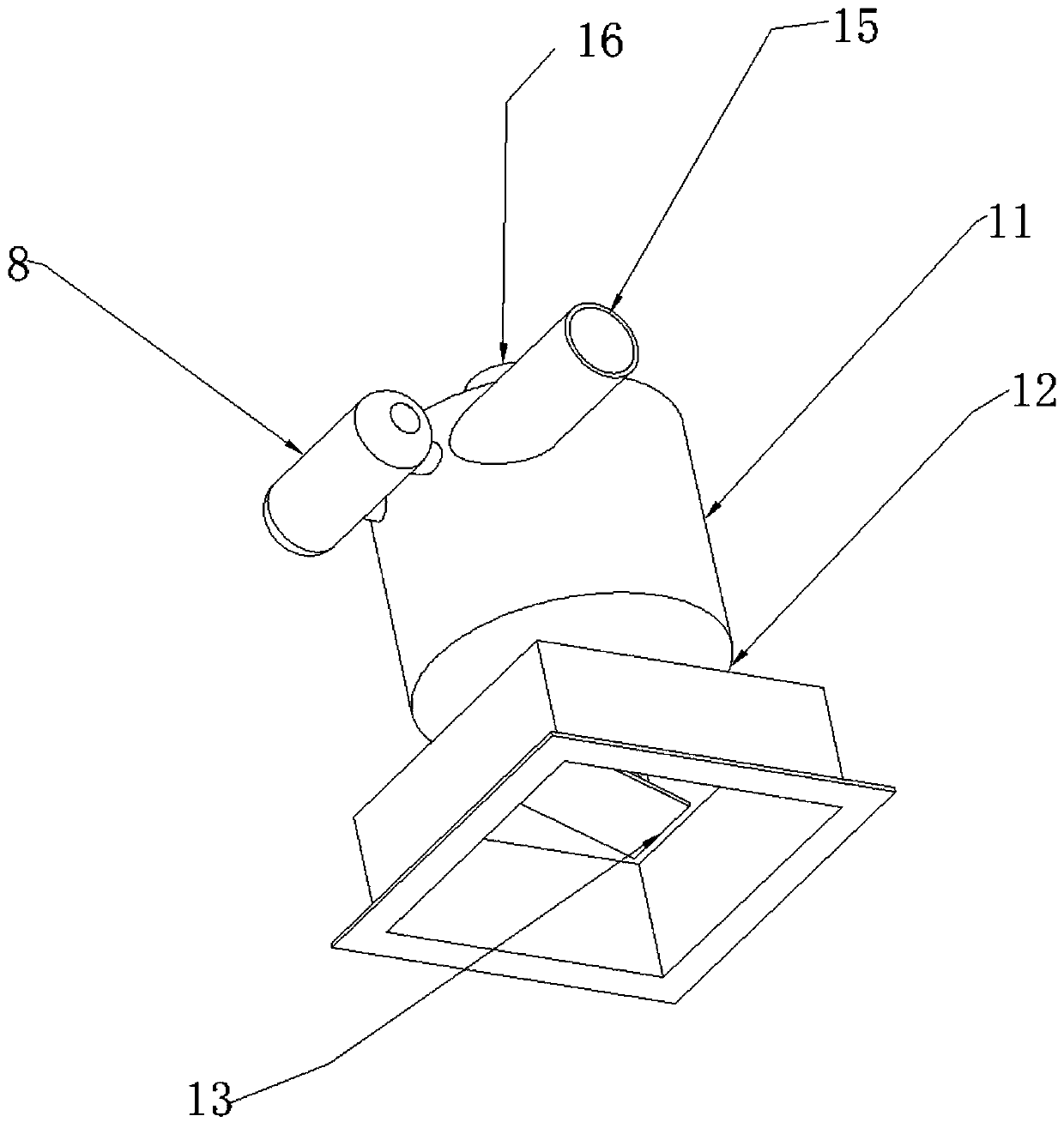

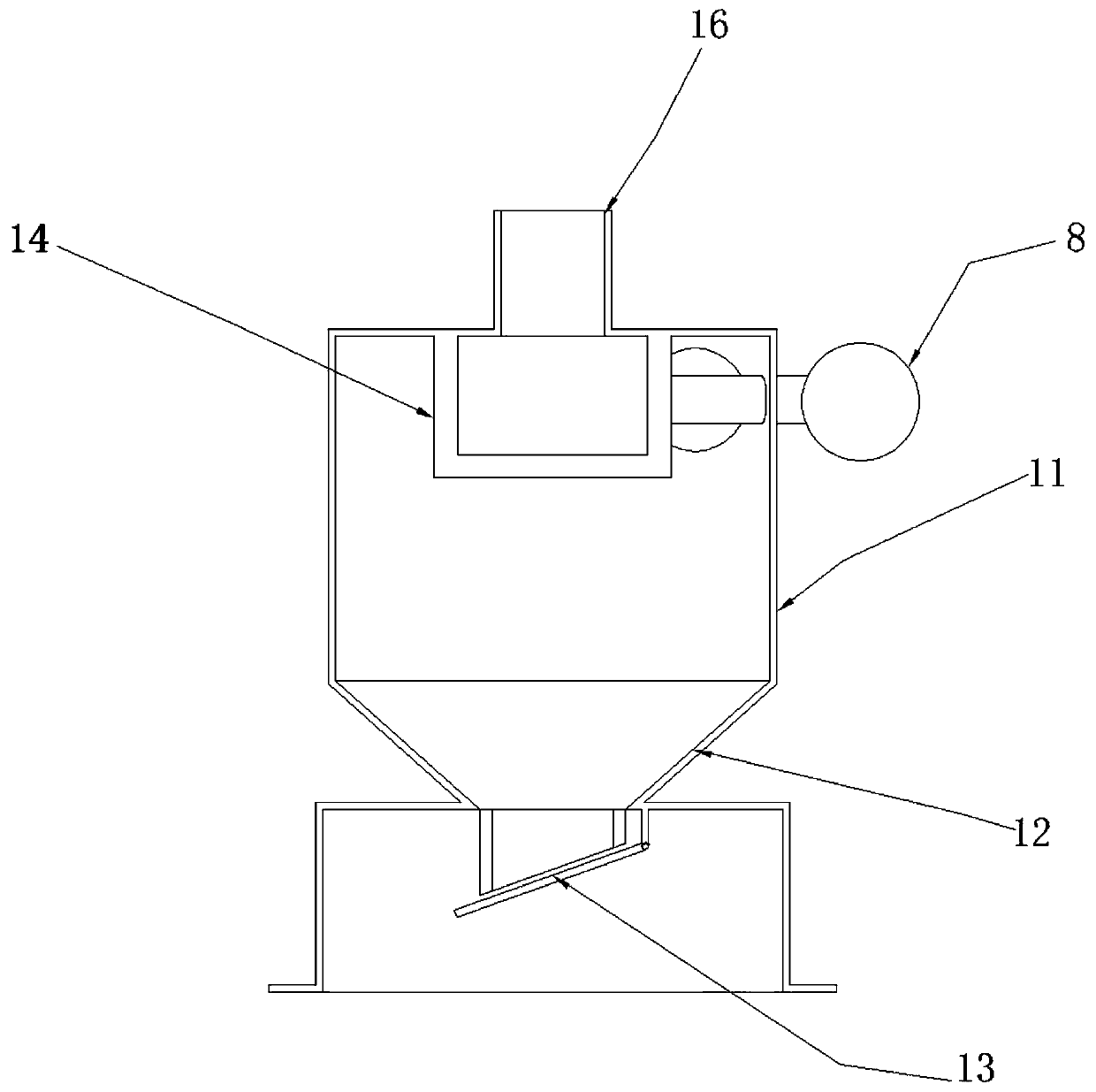

[0033] see figure 1, the circulating feeding equipment with powder recovery function provided by the present invention comprises an air powder separation device 1, a powder falling device 2, a printing motion device 3 and a powder spreading device 4; the air powder separation device is located in the powder falling device Above, the powder falling device and the powder spreading device are located above the printing motion device from top to bottom, and a redundant powder collecting device 5 is arranged below the printing moving device; Powder and a storage hopper 6 for collecting excess powder; a manual unloading valve 61 is provided below the storage hopper; the powder and air in the storage hopper are sucked into the air powder separation device through the first air pipe 7, and are separated and separated The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com