Small-aperture capacitive electromagnetic flow sensor

An electromagnetic flow, capacitive technology, applied in the application of electromagnetic flowmeter to detect fluid flow, volume/mass flow generated by electromagnetic effect, measure flow/mass flow, etc., can solve the problem of poor weldability, low reliability and poor reliability. and other problems, to achieve the effect of improving the induction capacitance value, good capacitance consistency, and stable capacitance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the present invention clearer, the various embodiments to be described below will refer to the corresponding drawings, and these drawings constitute a part of the embodiments, which describe various possible implementations of the present invention. kind of embodiment. It is to be understood that other embodiments may be utilized or structural and functional modifications may be made to the embodiments set forth herein without departing from the scope and spirit of the present invention.

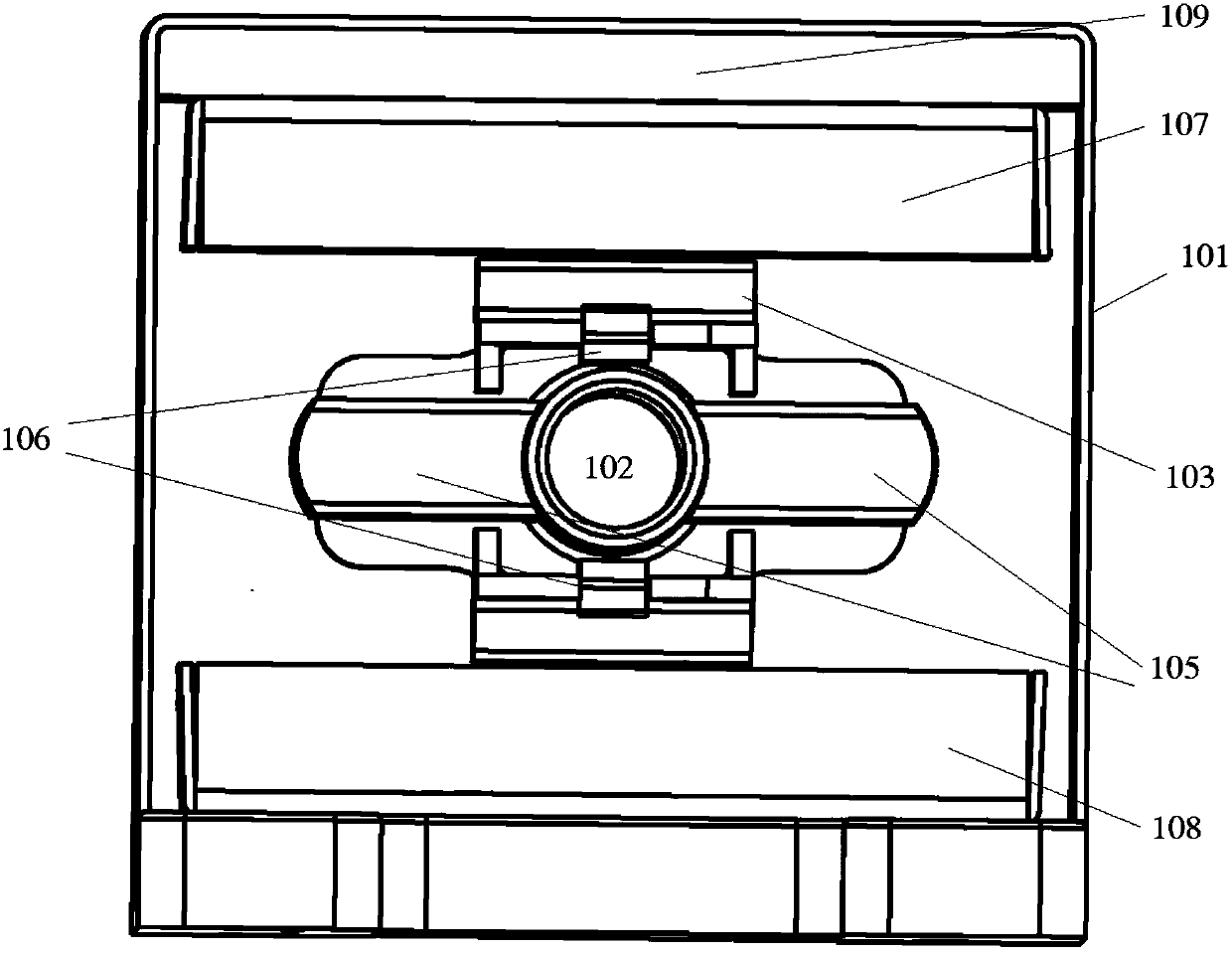

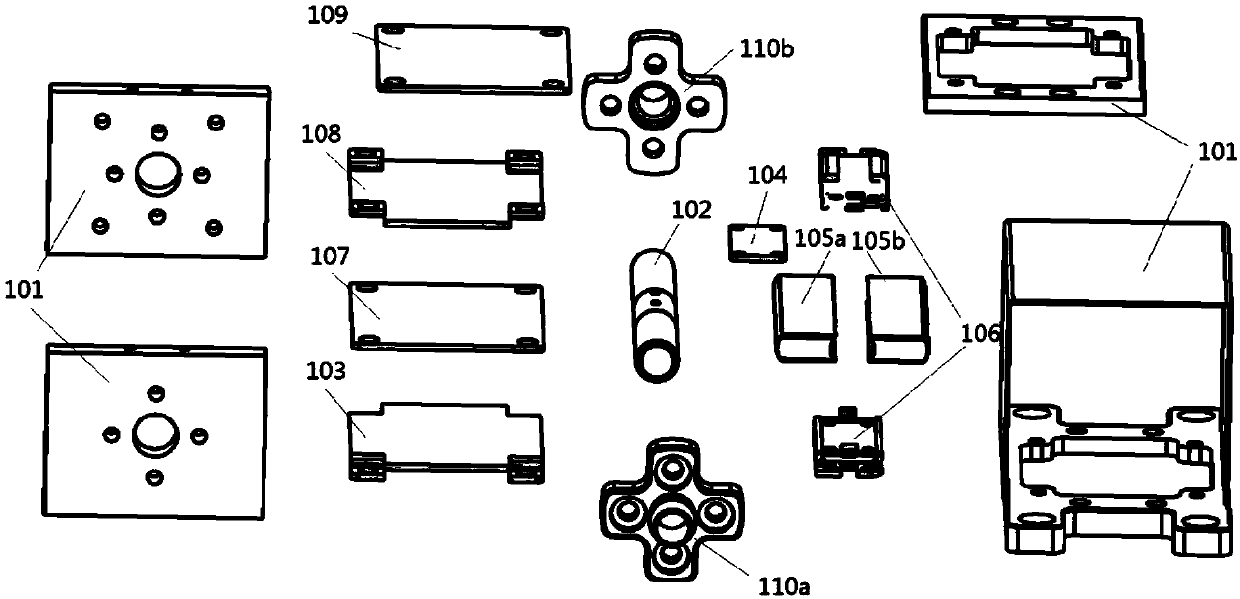

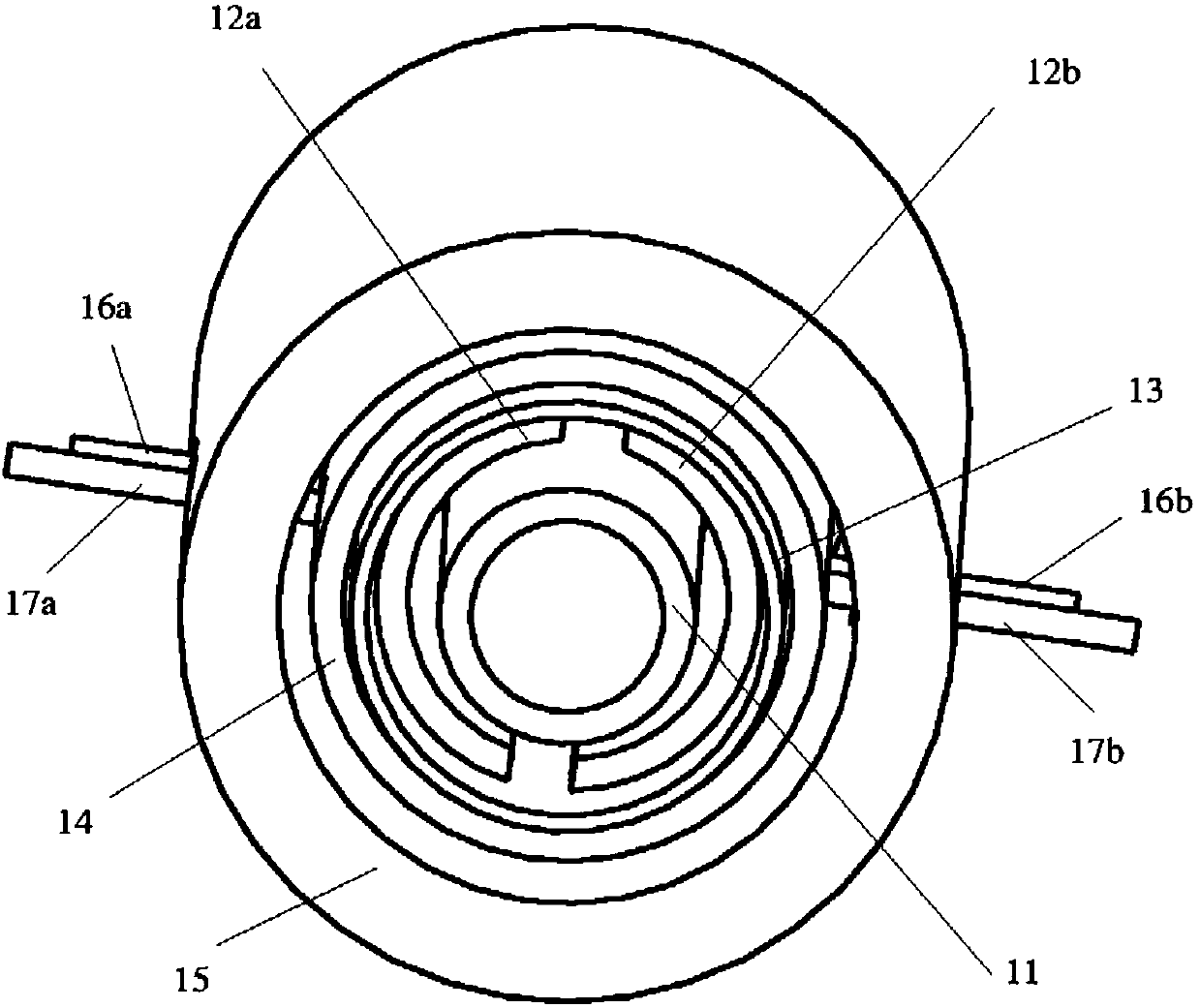

[0026] Such as Figure 1-2 As shown, the present invention provides an embodiment of a small-aperture capacitive electromagnetic flow sensor, including a housing 101, a measuring conduit 102 installed in the cavity of the housing 101, a control device 103, an excitation circuit 104, an excitation coil 105, and a signal electrode 106, a signal amplifier 107, a digital-to-analog converter 108, and a power supply 109 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com