Control method based on engine cylinder cover lifting mechanism

A lifting mechanism and engine body technology, applied in program control, electrical program control, general control system, etc., can solve the problems of collision dead block, high maximum running speed, and lift mechanism setback, etc., to reduce collision dead block and avoid high speed. The effect of high, smooth switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment, the present invention is further described, but does not constitute any restriction to the present invention, anyone makes the limited number of amendments in the scope of claims of the present invention, still within the scope of claims of the present invention.

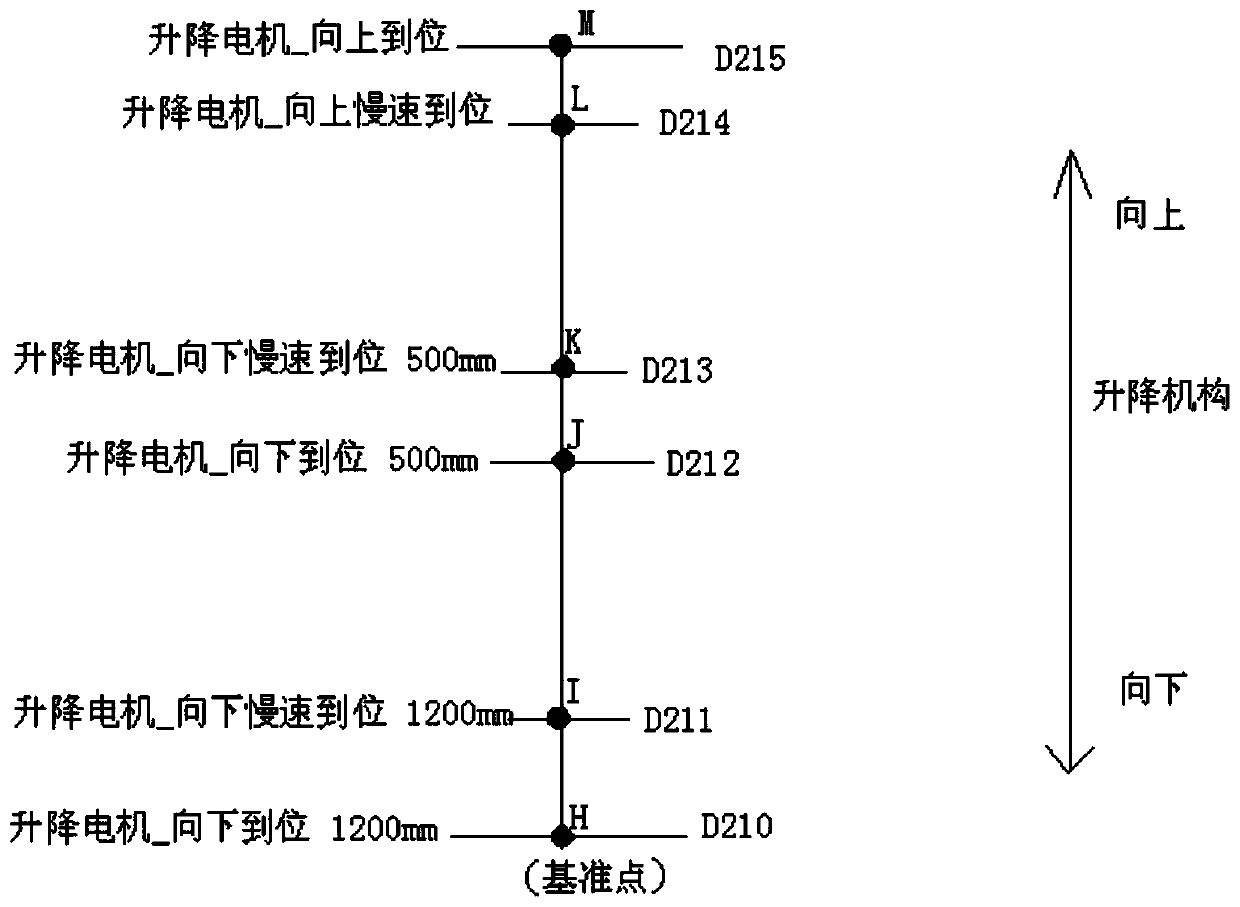

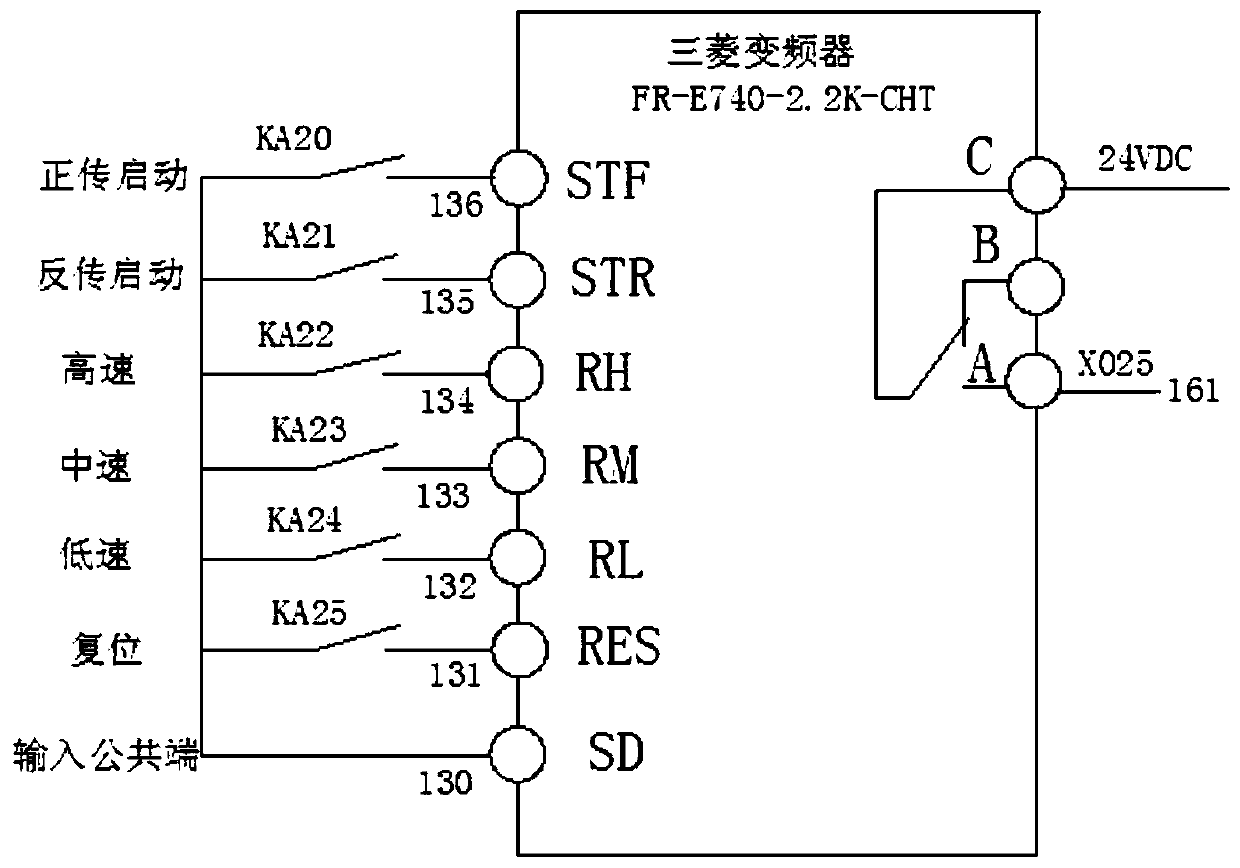

[0020] A control method based on the engine cylinder head lifting mechanism of the present invention divides the running track of the lifting mechanism into several running intervals, and respectively sets the acceleration corresponding to each running interval. The current position value of the lifting mechanism is obtained in real time, and the operating range of the lifting mechanism is determined by comparing the comparison array with the value, and the lifting mechanism is operated at the acceleration corresponding to the operating range through the motor frequency conversion control mode. By rationally dividing the running track of the lifting mechanism, the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com