Paper shredder capable of automatically packaging shredded paper and automatic shredded paper packaging method of paper shredder

A paper shredder and paper shredding technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of cumbersome and difficult operation, easy overflow of shredded paper, and achieve the effect of simplified operation steps and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

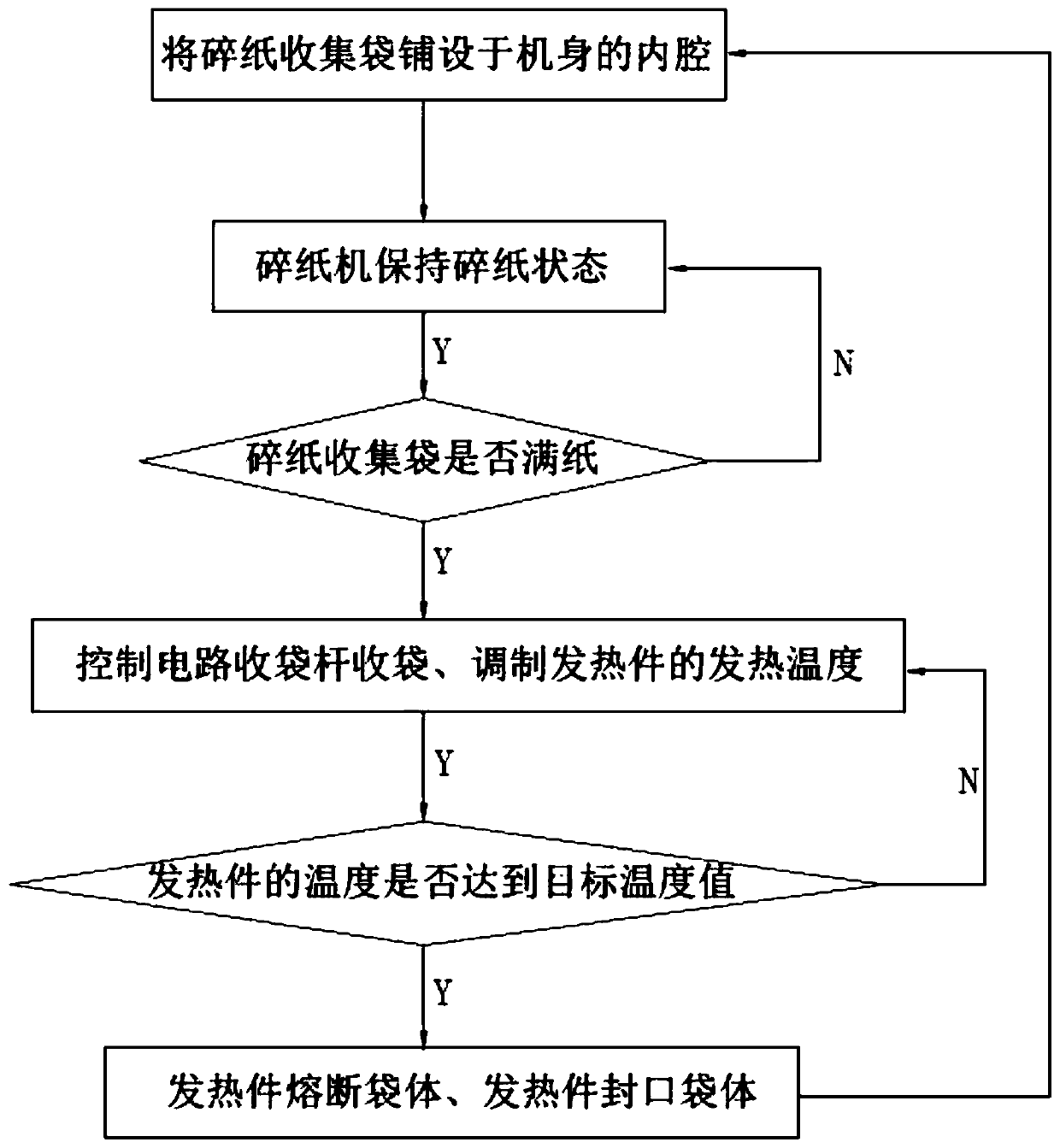

[0064] A paper shredder automatic packing and shredding method provided by the present invention specifically includes the following steps,

[0065] 1) In the bag-putting step, the shredded paper collection bag 01 is stored in the inner cavity of the shredded paper collection bag storage box 3. Preferably, a plastic through-bag with one end sealed without breakpoints is selected as the shredded paper collection bag 01, and the Shredded paper collection bag 01 pulls out the bag body of appropriate length, so that the bag mouth opens toward the paper drop opening 31;

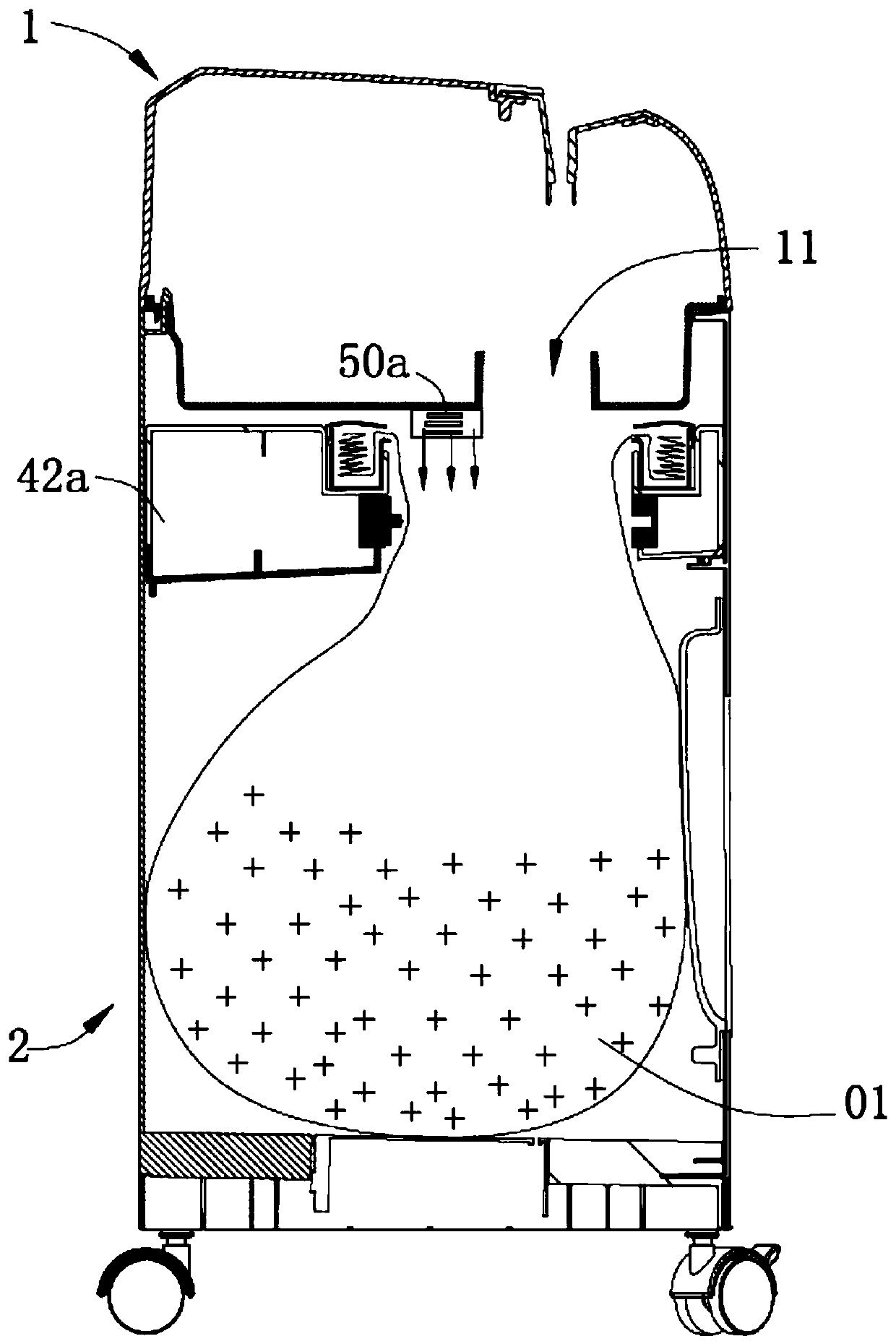

[0066] 2) In the laying step of the shredded paper collection bag, air is kept blowing to the shredded paper collection bag 01 through the air supply fan 50a and / or the inner cavity of the fuselage 2 is kept ventilated by the exhaust fan 50b, so that the bag body continues to move toward the inside of the fuselage 2. The cavity is opened downward or towards the outside, at least when the bag body covers a specifie...

Embodiment 2

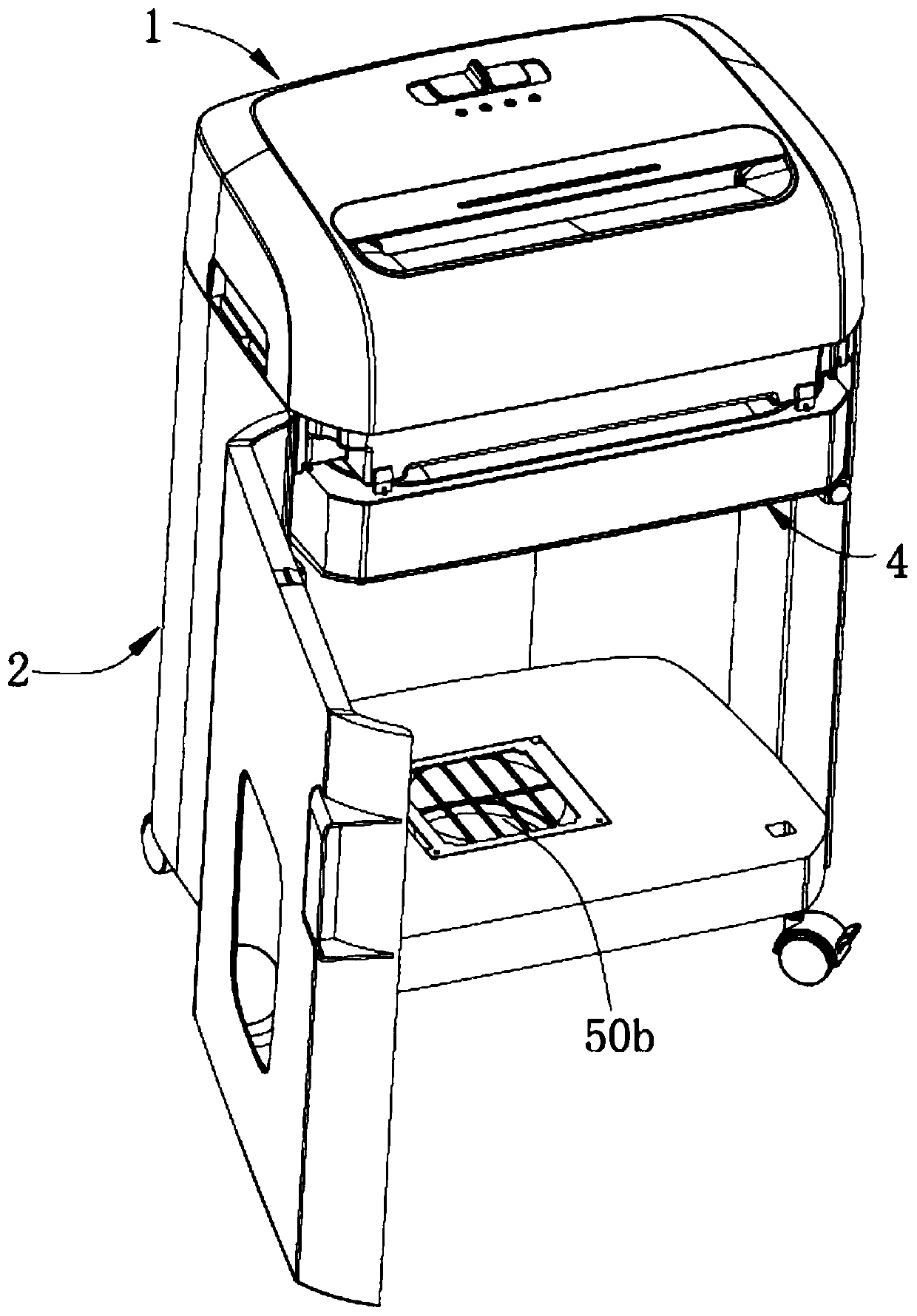

[0082] Such as Figures 2 to 12 As shown, a shredder for automatically packing and shredding provided by the present invention includes a fuselage 2, a shredder head 1 installed on the upper end of the fuselage 2, and a control circuit. The upper part of the shredder head 1 is provided with The paper inlet and the lower part are provided with a chip discharge port 11, and the inside of the shredder head 1 is provided with a shredder core, and the shredder core is equipped with a shredder motor, a gear transmission mechanism and two shredder blades, The drive is connected to the gear transmission mechanism, and the gear transmission mechanism is connected to the shredding knife stick. A paper shredding knife stick includes a knife shaft and multiple shredding blades. Each shredding blade is arranged on the same knife shaft at intervals. The corresponding two adjacent shredding blades are sheared and matched, and the control circuit is electrically connected to the shredding mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com