Polishing device for double-sided lamp decoration ball

A polishing device and lighting technology, used in grinding/polishing safety devices, grinding/polishing equipment, machine tools suitable for grinding workpiece planes, etc. and other problems, to achieve the effect of high adsorption firmness, high safety, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for limiting the present invention.

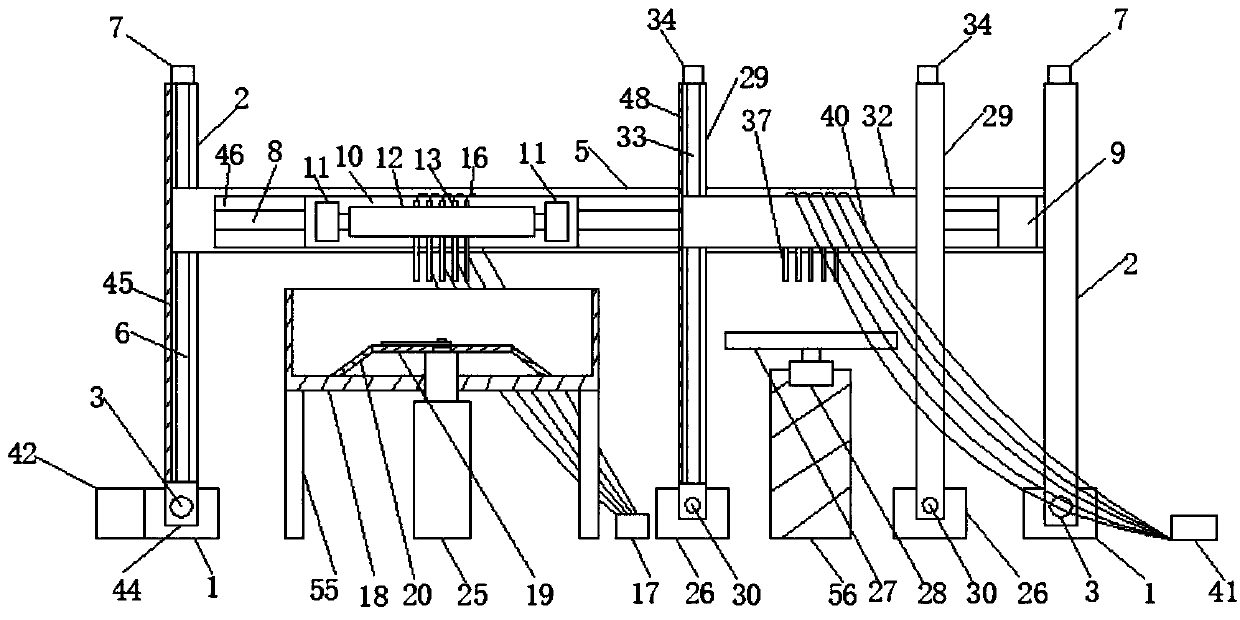

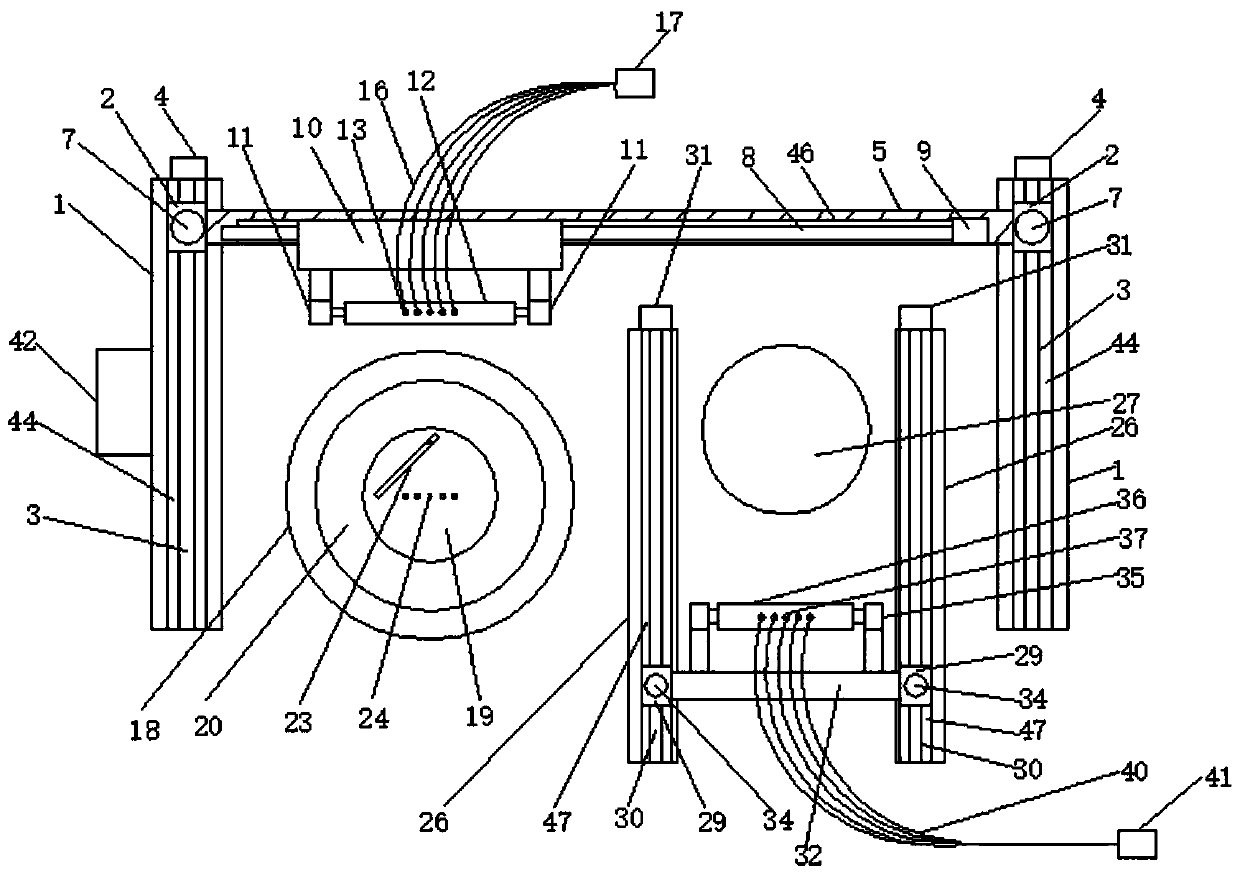

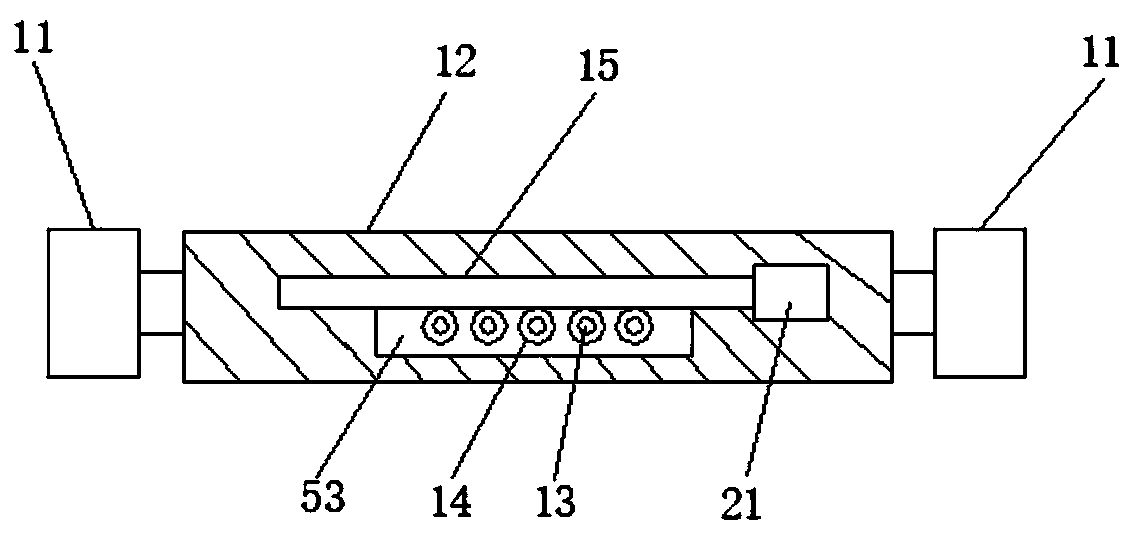

[0022] Example. A polishing device for a double-sided lighting ball, consisting of Figures 1 to 10As shown, it includes two parallel No. 1 guide rails 1, and each No. 1 guide rail 1 is provided with a No. 2 guide rail 2 perpendicular to the No. 1 guide rail 1; the bottom end of each No. 2 guide rail 2 is threaded through a threaded hole No. 1 threaded rod 3 is connected, and one end of each No. 1 threaded rod 3 is connected with No. 1 motor 4; No. 3 guide rail 5 perpendicular to No. 2 guide rail 2 is connected between the two No. 2 guide rails 2. No. two threaded rods 6 are connected to the two ends of the threaded holes; No. two threaded rods 6 are located on the No. two guide rail 2, and one end of each No. two threaded rod 6 is connected with No. two motor 7; the No. three guide rail...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap