A special turnable support device for hanging formwork and its construction method

A technology of supporting device and hanging formwork, applied in the field of municipal engineering supporting device and housing construction, can solve the problems of polluting the environment, large deviation of concrete height difference, affecting construction period and quality, etc. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

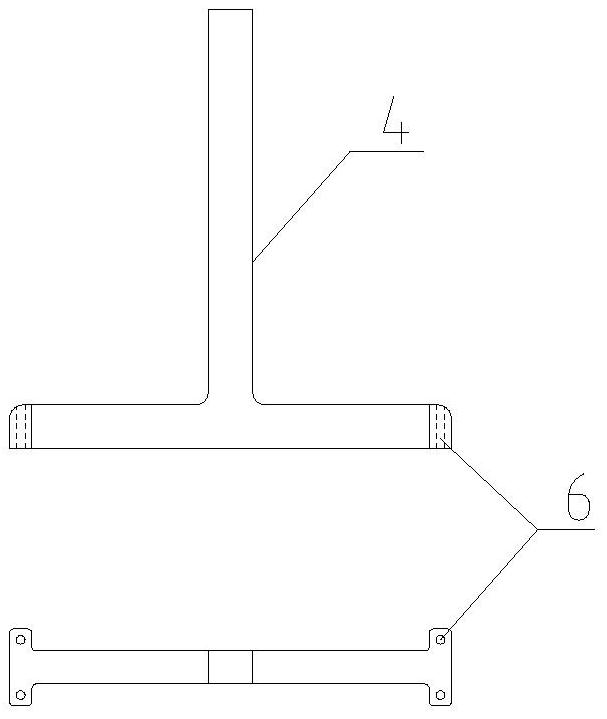

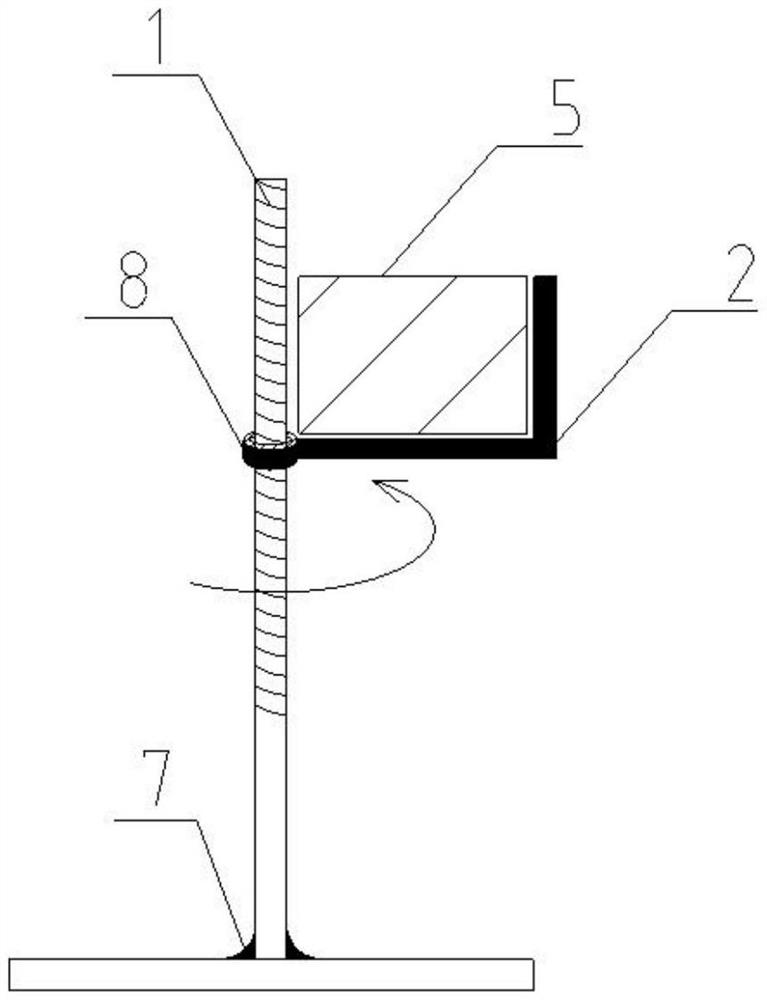

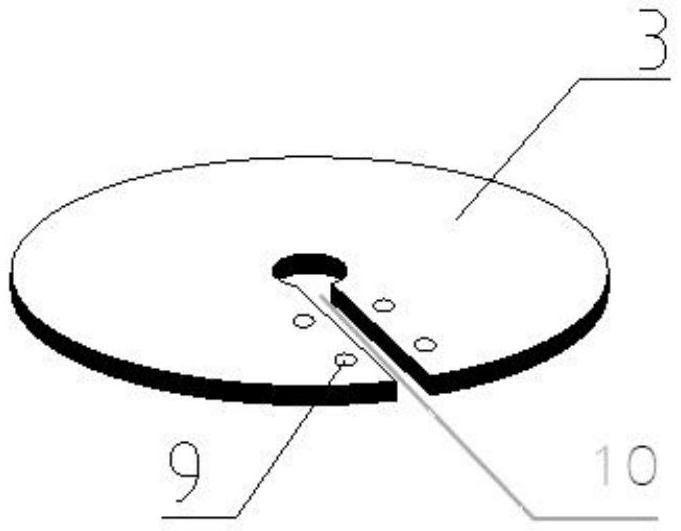

[0021] A special turnable support device for hanging molds, including a T-shaped screw 1, an L-shaped steel support 2, a rubber gasket 3, a T-shaped screw sleeve 4, and screws. The T-shaped screw 1 is engraved with threads, and the L-shaped The end of the steel bar support 2 is fixedly connected with a nut 8, the nut 8 is threaded with the T-shaped screw 1, and the rubber gasket 3 is provided with an accommodation hole 10, and the nut 8 and the bottom edge of the L-shaped steel bar support 2 can be embedded in the accommodation hole 10 , through the detachable connection of the fixing piece and the rubber gasket, the fixing piece can be tie wire, etc., the T-shaped screw 1 can be loaded into the T-shaped screw sleeve 4, and the vertical rod of the T-shaped screw sleeve 4 is larger than the T-shaped screw The vertical bar of 1 is short, and the cross bar of T-shaped screw cover 4 is longer than the cross bar of T-shaped screw rod 1, and T-shaped screw cover cross bar is away fro...

Embodiment 2

[0023] Based on Example 1, Example 2 lists several preferred technical features, and Example 1 can choose one or most of them in combination to form multiple different technical solutions.

[0024] Preferably, in the above-mentioned revolving support device dedicated to hanging molds, two wire-binding holes 9 are opened on both sides of the accommodation hole.

[0025] Preferably, in the above-mentioned turntable support device dedicated to hanging molds, the thickness of the rubber gasket is equal to the diameter of the L-shaped steel bar support.

[0026] Preferably, the above-mentioned turntable supporting device for hanging molds, the L-shaped steel bar support is composed of a horizontal bar and a vertical bar, the horizontal bar is engraved with threads, and the end of the vertical bar is fixedly connected with a fixed ring, and the inner part of the fixed ring is engraved There are threads, fixed rings and cross-bar threaded connections to realize the adjustable width o...

Embodiment 3

[0029] A construction method for a turnable support device dedicated to hanging formwork:

[0030] ① Put the T-shaped screw sleeve on the T-shaped screw, the L-shaped steel support is installed on the T-shaped screw through the nut, the bottom of the L-shaped steel support is embedded in the accommodation hole of the rubber gasket, and can be flexibly connected to the rubber gasket through the fixing piece ;

[0031] ②Fix the installed turntable support device for hanging formwork on the low-span formwork where the hanging formwork needs to be installed with nails, and fix them in turn;

[0032] ③Clamp the wooden frame or section steel in the L-shaped steel support of the special turnaround support device for hanging mold;

[0033] ④ Pouring concrete;

[0034] ⑤Remove the rubber gasket from the concrete floor; rotate the L-shaped steel bar support to separate the L-shaped steel bar support from the T-shaped screw; remove the formwork, and take the T-shaped screw from the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com