Construction reinforcing structure for high-space large-span section steel concrete structure beam hanging mold and construction method thereof

A concrete structure and reinforcement structure technology, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, building structure, etc., can solve the problems of low construction efficiency, high engineering cost and difficult operation and other issues, to achieve high construction efficiency, high safety factor, and improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

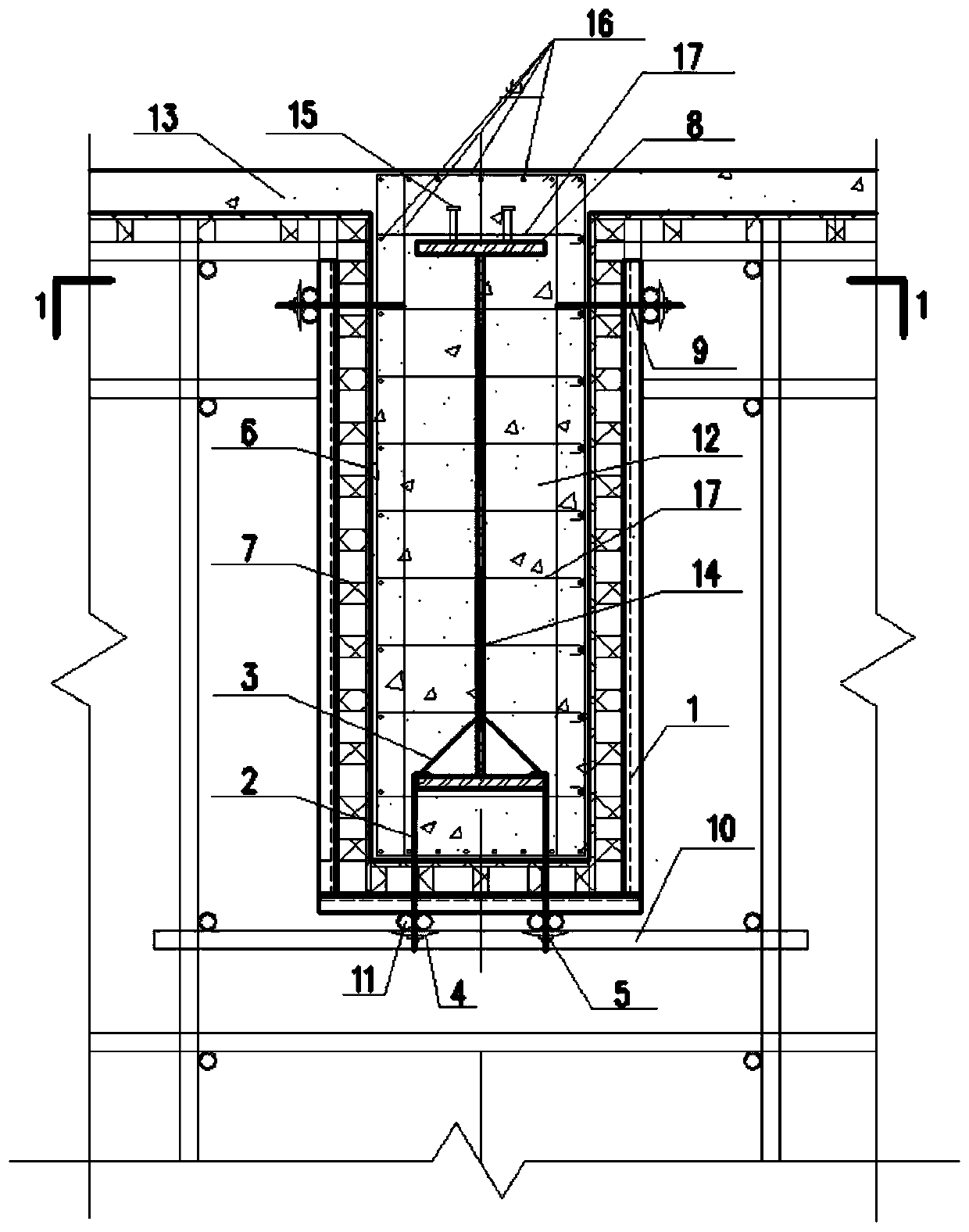

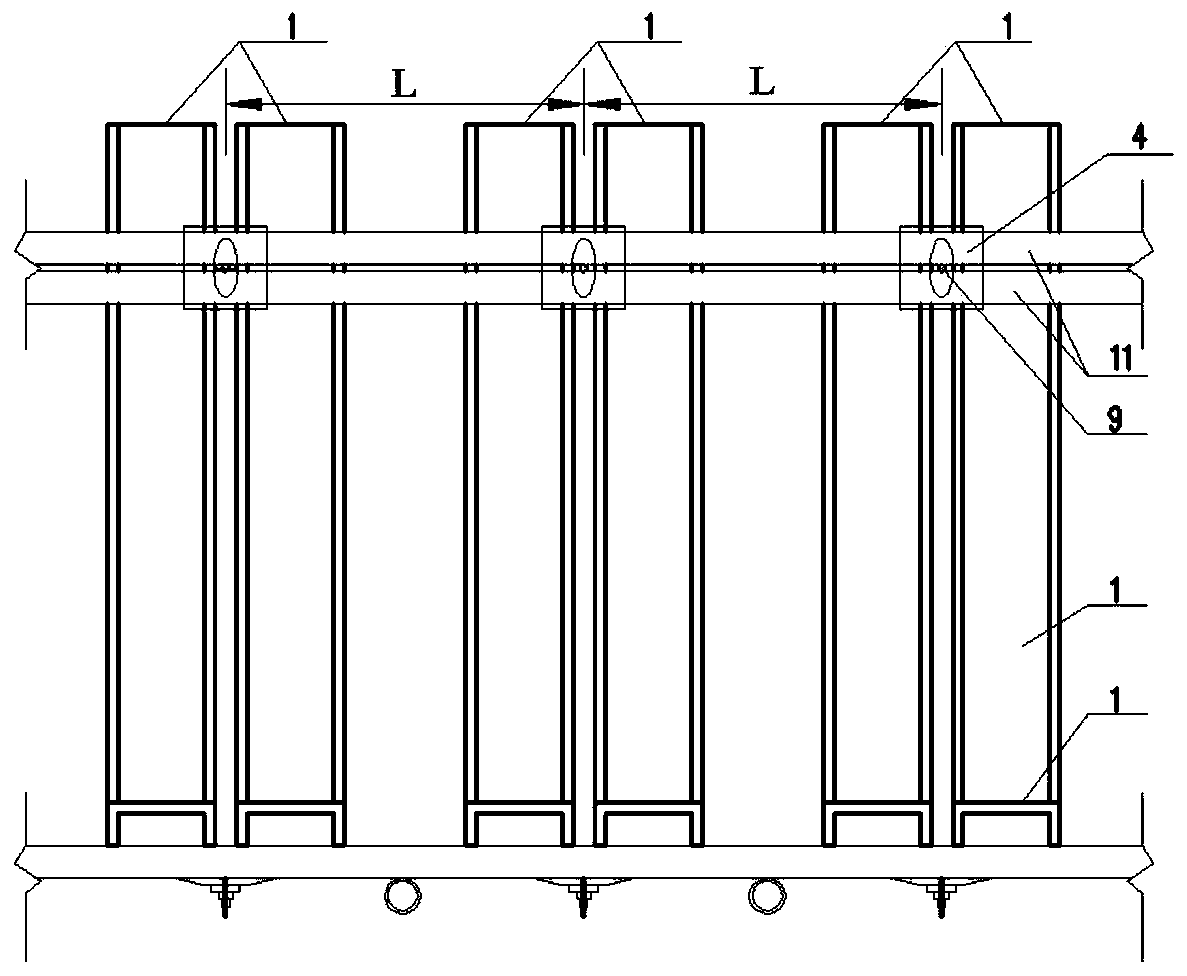

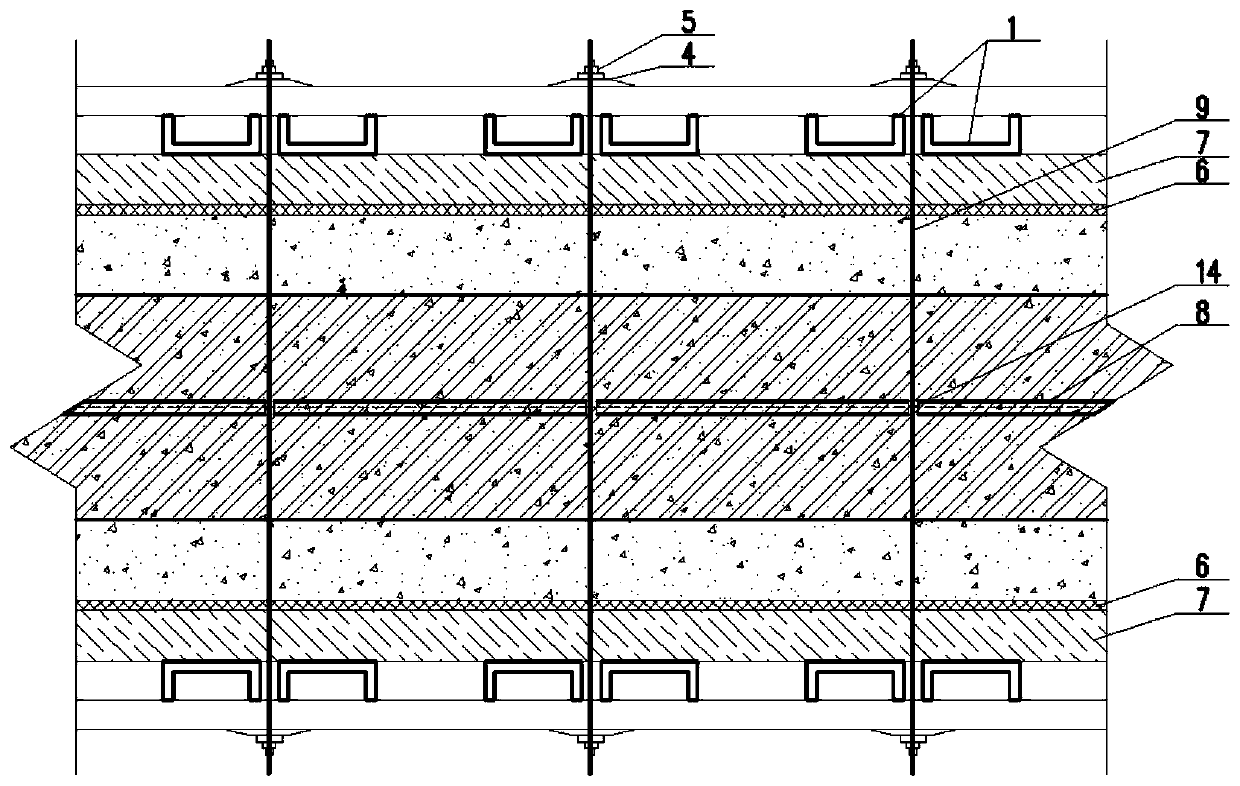

[0024] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure 1-3 As shown, a high-space and large-span steel concrete structure beam hanging formwork construction reinforcement structure includes prefabricated steel beams that have been fixed on the construction site, and the beam bottom form and beam side formwork 6 and wooden frame 7 that are prefabricated in place. The bottom of the lower flange plate of the shaped steel beam is welded and suspended with several hook screws 2. The bottom of the hook screws passes through the inner formwork in the gap between the upper wooden beams 7 of the formwork 6, and the vertically arranged steel pipes and fasteners are used to fix the suspension "U". U-shaped splicing channel steel 1, "U"-shaped splicing channel steel is spliced into a "U" shape by three channel steels and welded firmly, and every two "U"-shaped splicing grooves are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com