An integrated drilling and grinding tool for precision machinery manufacturing

A technology of precision machinery, drilling and grinding, which is used in the manufacture of tools, drilling accessories, drilling and other directions. It can solve the problems of substandard workpiece size and inability to combine operations, and achieve the effect of facilitating the operation of the tool.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

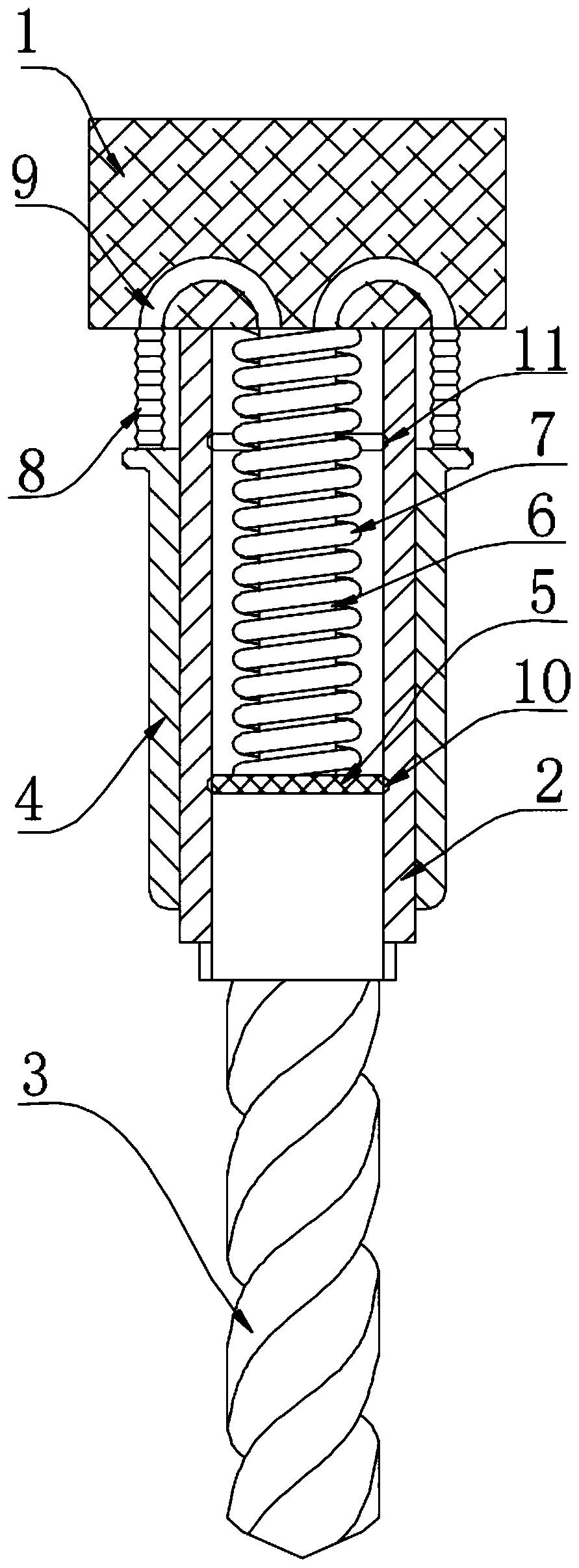

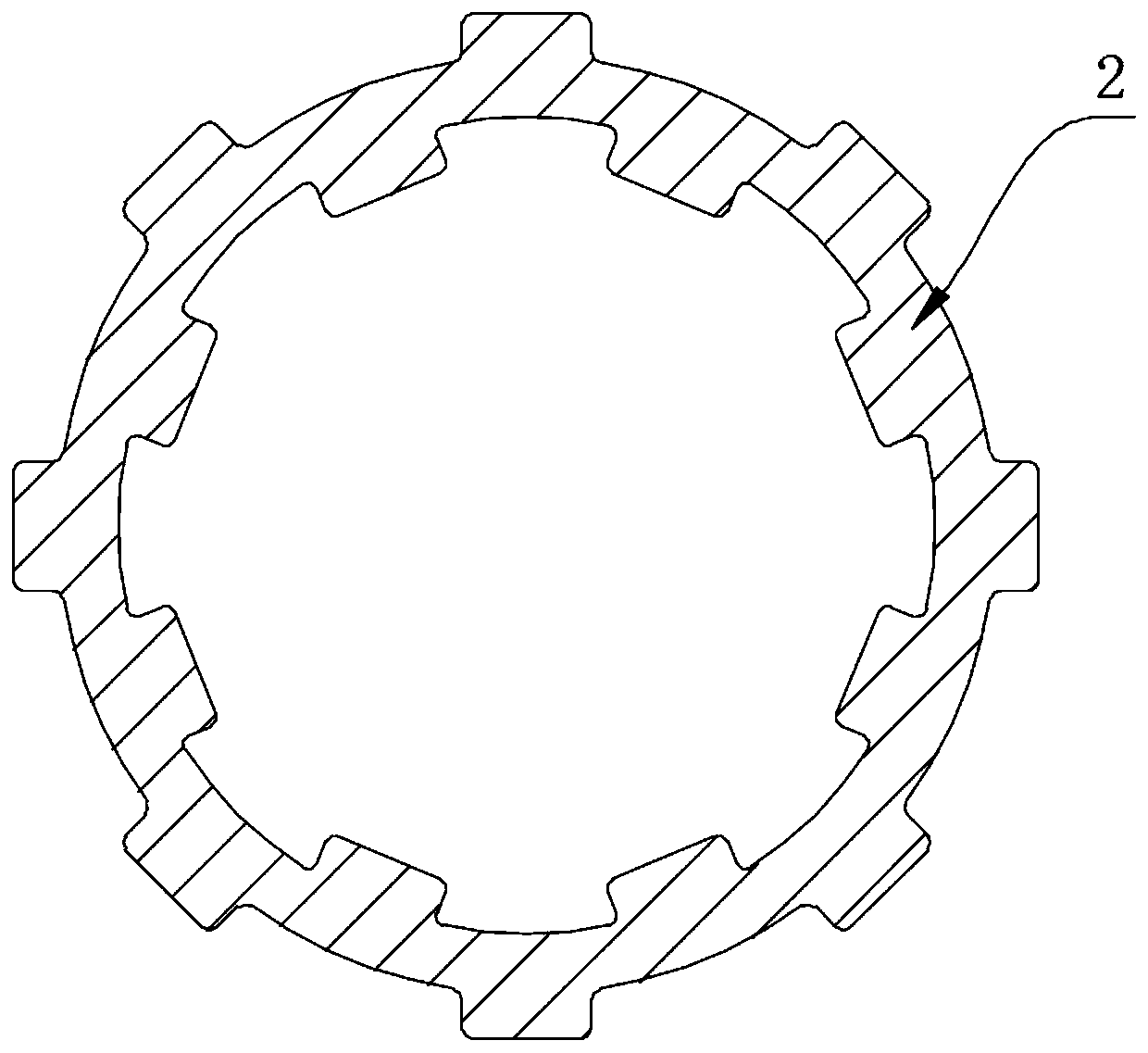

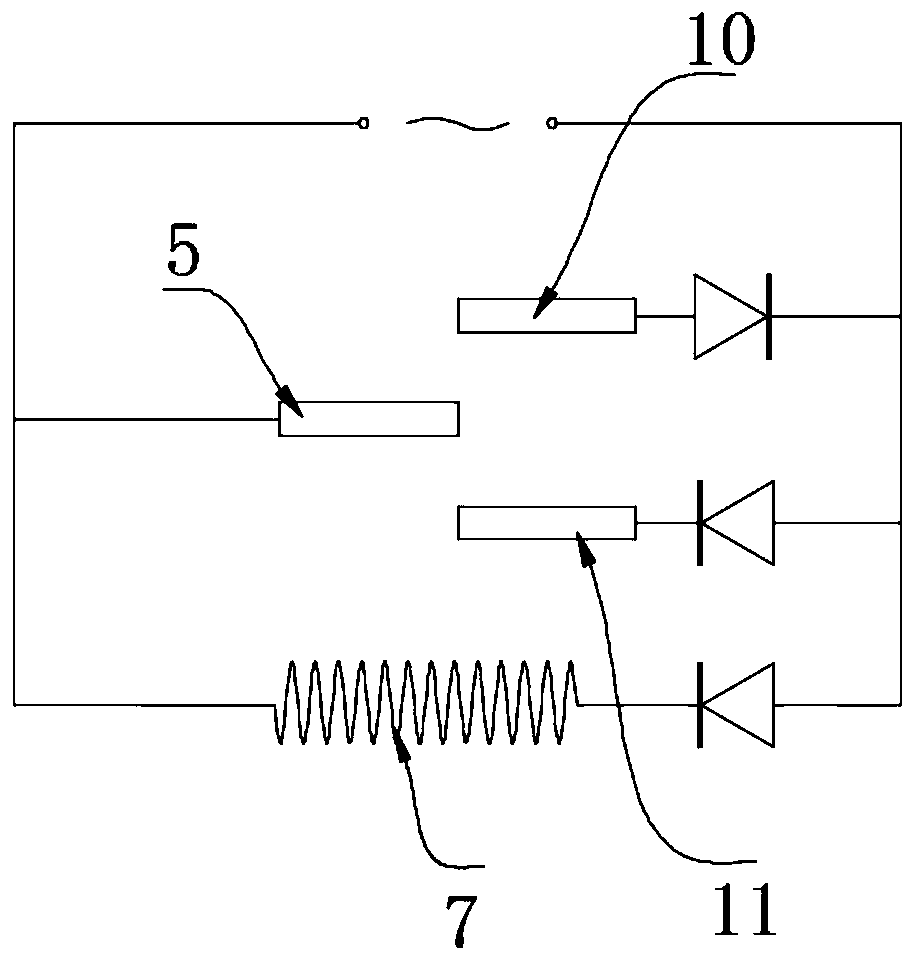

[0020] refer to Figure 1-3 , an integrated drilling and grinding tool for precision machinery manufacturing, including a tool seat 1, a double-sided spline ring 2 is fixed on the lower wall of the tool seat 1, and a drill bit is slidingly sleeved inside the double-sided spline ring 2 in the up and down direction 3. The double-sided spline ring 2 is connected with a ring-shaped grinding head 4. The end of the drill bit 3 close to the tool holder 1 is fixed with a conductive block 5. The conductive block 5 and the tool holder 1 are fixedly connected with a flexible inner tube. 6. The grinding head 4 and the tool holder 1 are fixedly connected with a plurality of flexible outer tube bodies 8, and the tool holder 1 is provided with a communication cavity 9 equal to the outer tube body 8, and each communication cavity 9 is connected to the corresponding position. The outer tube body 8 is in communication, and the end of each communication cavity 9 away from the outer tube body 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com