Pull rod device with central pipeline and cutter loosening and clamping method

A tie rod device and center tube technology, which is applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of inability to blow out airflow, affecting the machining accuracy of the spindle, and difficulty in meeting machining requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] 下面结合附图和实施例对本发明作更加详细的描述。

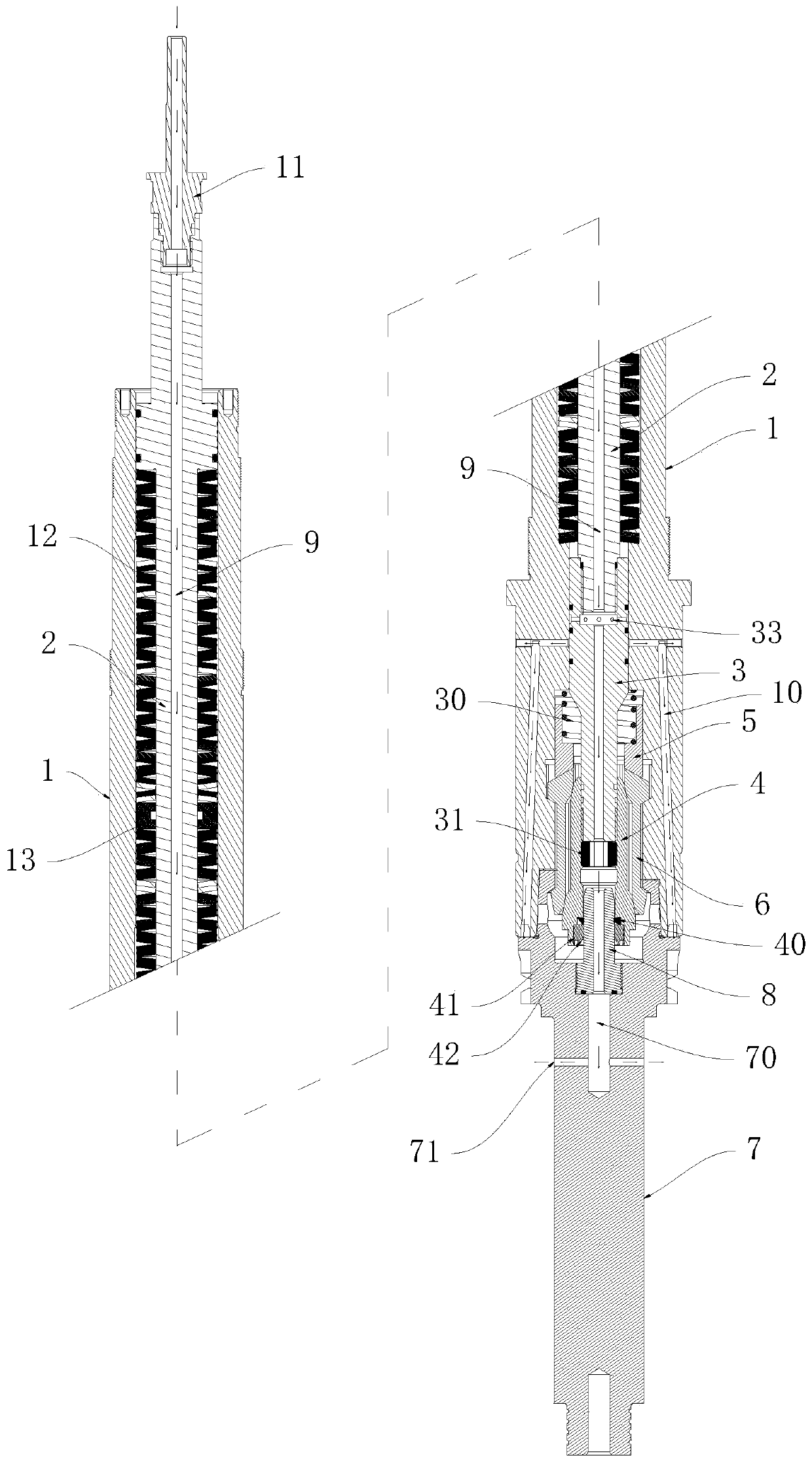

[0018] 本发明公开了一种具有中心管路的拉杆装置,请参见 figure 1 ,其包括有转子1,所述转子1内设有拉杆2、前连接杆3、撑杆4和拉爪座5,所述前连接杆3固定于所述拉杆2的前端,所述撑杆 4固定于所述前连接杆3的前端,所述拉爪座5套设于所述前连接杆3的外侧且二者活动连接,所述拉爪座5的前端设有拉爪6,所 Related claw 6 surrounds the support rod 4. The front end of the rotor 1 has a knife handle 7. 卡设于所述拉爪6与所述转子1之间;

[0019] 所述拉杆2、前连接杆3和撑杆4均呈中空状,所述刀柄7后端的中心处固定有内冷管8,所述内冷管8插设于所述撑杆4的前端,所述刀柄7内开设有刀柄气道70,所述拉杆2、前连接杆3、撑杆4、内冷管8和刀柄气道70依次连通而形成中心管路9,所述刀柄7的侧部开设有与所述刀柄气道70相互连通的刀柄气孔71。

[0020] 上述装置中,所述刀柄7上设置了刀柄气道70和刀柄气孔71,所以在松刀时,利用所述拉杆2带动所述前连接杆3和撑杆4向前滑动,使得 所述撑杆4与所述拉爪6分离,所述拉爪6弹性复位,所述刀柄7被松开,利用所述撑杆4将所述刀柄7顶出,同时,由所述 The back end of the trolley 2 is injected into the airflow within the center pipeline 9, and the knife handle 7 is cleaned by the airflow; when the main axis executes the knife movement, the tie rod 2 drives the front connector 3 and the supporting support. 杆4向后滑动,利用所述撑杆4将所述拉爪6撑开,将所述刀柄7的后端夹紧于所述拉爪6与所述转子1之间,同时,由所 述拉杆2的后端向所述中心管路9内注入气流或者水流,该气流或者水流经由刀柄气道70和刀柄气孔71向外喷出,进而对所述刀柄7以及安装于所 述刀柄7上的刀具进行降温。 In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com