A production equipment for sponge paper cutting strips

A production equipment and strip cutting technology, which is applied in thin material processing, metal processing, sending objects, etc., can solve the problems of reducing production efficiency, increasing labor costs, sponge paper transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

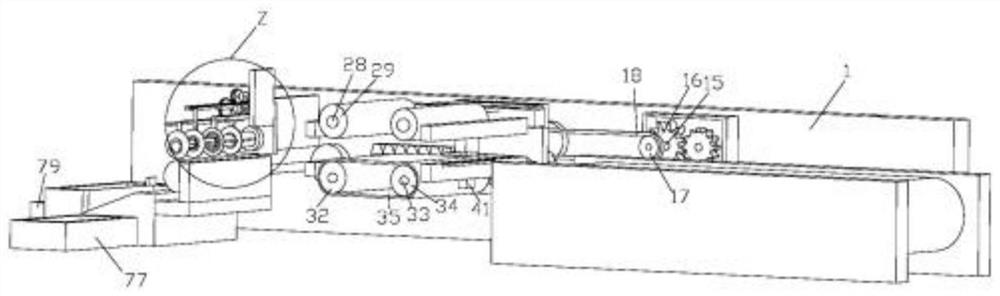

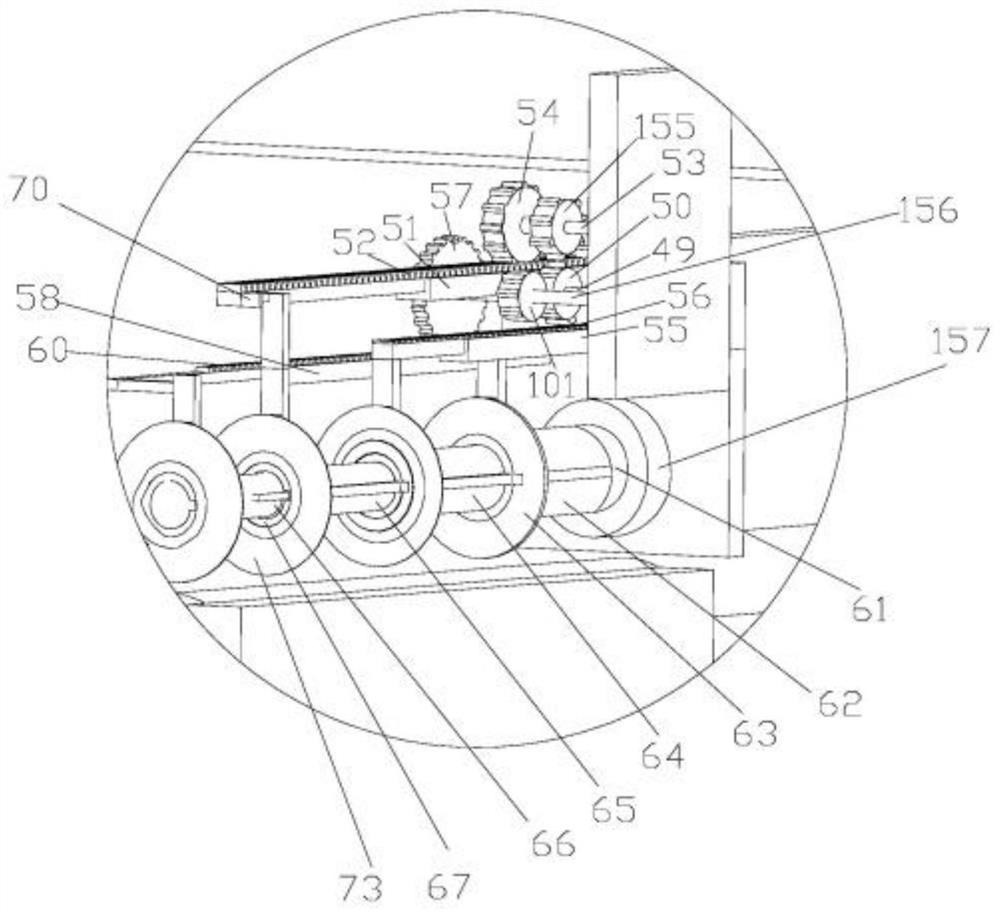

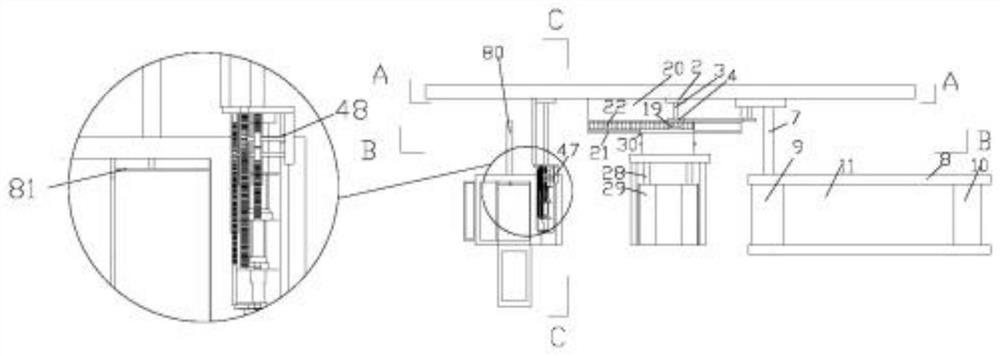

[0025] Such as Figure 1-10 As shown, a production equipment for sponge paper cut strips, including a separator 1, a conveying device arranged on the front end of the separator 1, a crushing device arranged on the left side of the conveying device, and a The feeding device, the cleaning device arranged on the crushing device, the conveying device includes a first driving member 2 fixedly arranged on the front end of the partition 1, a second power shaft 3 arranged at the front end of the first driving member 2, a fixedly arranged The first pulley 4 on the outer surface of the second power shaft 3, the casing 5 fixedly arranged on the front end of the partition 1, the second casing space 6 arranged in the casing 5, and the casing 5 arranged on the front side of the partition 1 Two first vertical plates 8, the first transmission shaft 7 that is arranged on the front end of the partition plate 1, the first rolling cylinder 9 that is fixed on the front end of the first transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com