Pasture biogas raw material collecting device

A collection device and biogas technology, applied in waste fuel, construction, cleaning methods, etc., can solve the problems of inability to shovel excrement, more time and effort, and slow collection of excrement, so as to improve collection efficiency, prevent blockage, and save time. The effect of labor-saving collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

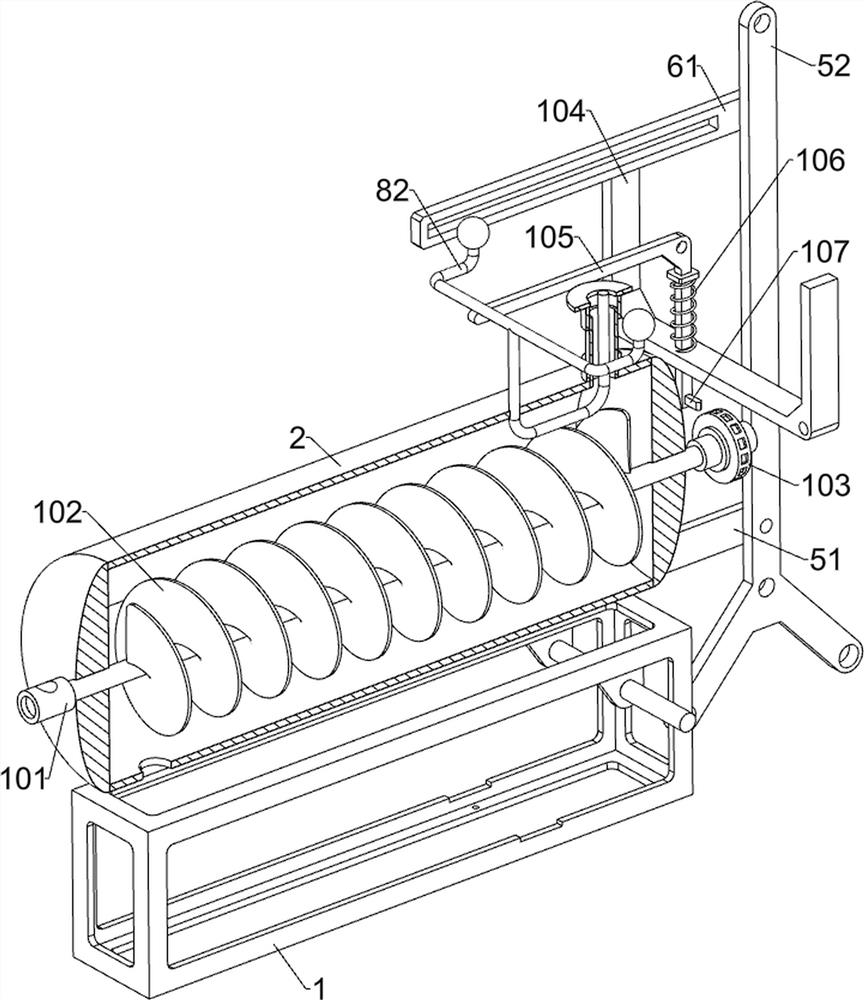

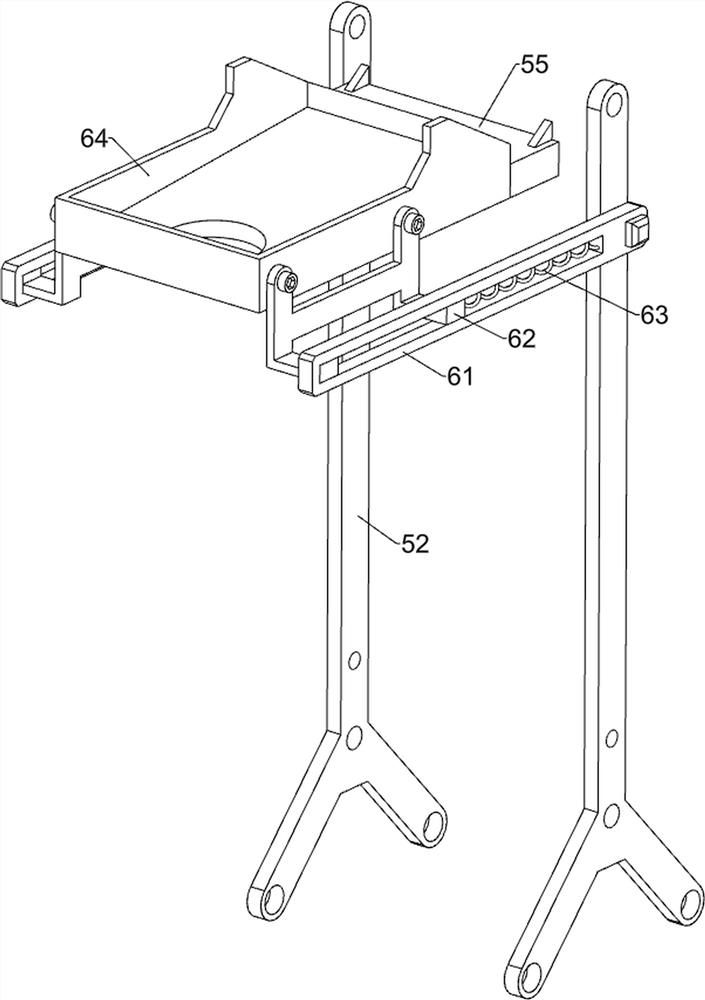

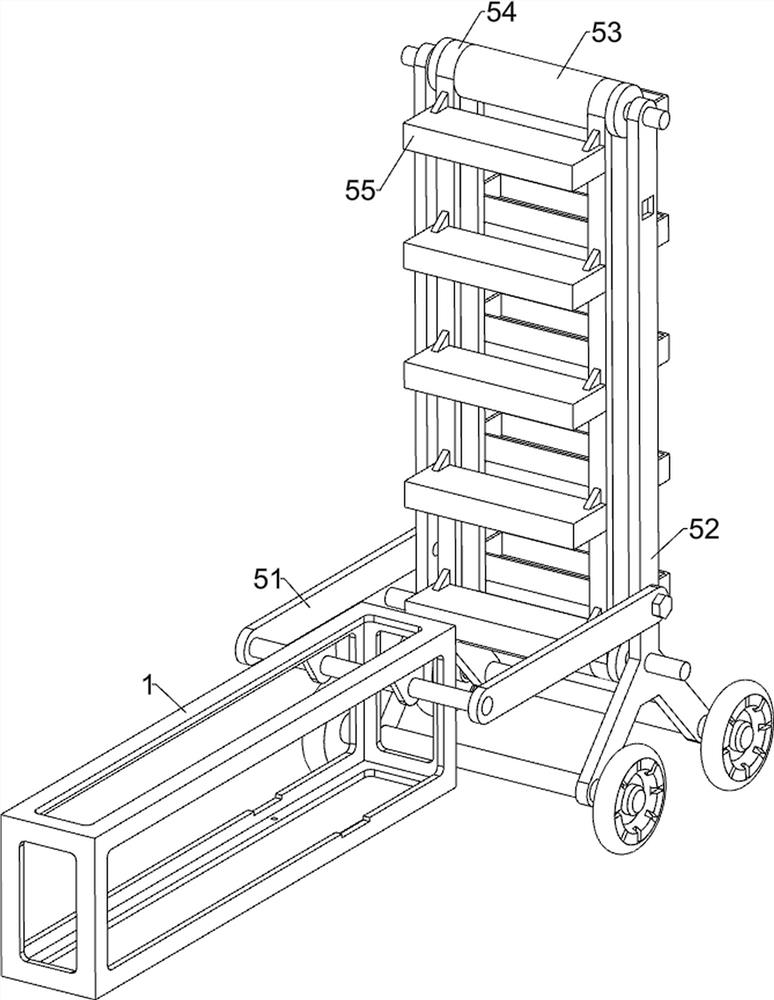

[0030] combine Figure 1-2 As shown, the present application provides a pasture biogas raw material collection device, including a moving frame 1, a collection tank 2, a discharge pipe 3, a feeding hopper 4, a feeding assembly 5, a feeding assembly 6 and a driving assembly 7, and the moving frame 1 The front and rear sides of the lower part are connected with wheels in a left-right and symmetrical rotation. The top of the mobile frame 1 is connected with a collection tank 2 by means of bolt connection. The collection tank 2 is used for storing animal feces. The discharge pipe 3, the lower part of the discharge pipe 3 is clamped with a plug, the discharge pipe 3 is used for discharging, and the rear side of the top of the collecting tank 2 is connected with a feeding hopper 4 by welding, and the feeding hopper 4 is used for feeding , the rear side of the moving frame 1 is provided with a feeding assembly 5, the upper part of the feeding assembly 5 is provided with a feeding ass...

Embodiment 2

[0041] On the basis of Example 1, combined with figure 1 and Image 6 As shown, it also includes a dredging assembly 8, the top rear side of the collection tank 2 is provided with a dredging assembly 8, and the dredging assembly 8 is used to dredge the collection tank 2 to prevent clogging, and the dredging assembly 8 includes a guide rod 81, a sliding rod 82, a second spring 83 and sphere 84, the top rear side of the collection tank 2 is connected with a guide rod 81 by welding, the guide rod 81 is slidably connected with a sliding rod 82, the sliding rod 82 is slidably connected with the collection tank 2, and the front part of the sliding rod 82 A second spring 83 is sleeved on the upper side. Both ends of the second spring 83 are connected with the sliding rod 82 and the guide rod 81 respectively. The front side of the top of the sliding rod 82 is symmetrically connected with a sphere 84, and the two spheres 84 are respectively connected with the two sliding plates. 62 co...

Embodiment 3

[0044] On the basis of Example 2, combined with figure 1 and Figure 8 As shown, a pusher assembly 10 is also included, and a pusher assembly 10 is provided between the collection tank 2 and the slide rail 61. The pusher assembly 10 is used to push the excrement on the rear side of the collection tank 2 to the front side to prevent the excrement All are stacked on the rear side of the collection tank 2. The pusher assembly 10 includes a rotating rod 101, a helical blade 102, a notch plate 103, a guide plate 104, a right-angled plate 105, a third spring 106 and a tooth block 107. The collection tank 2 The middle part is connected with a rotating rod 101 through a bearing, and the middle part of the rotating rod 101 is connected with a spiral blade 102 by welding. The spiral blade 102 is located in the collection tank 2, and the spiral blade 102 is used for the collection tank. Pushing, the rear side of the rotating rod 101 is connected with a notch plate 103 through a one-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com