Segmental precast variable-cross-section concrete box beam steel bar binding bed-jig

A technology for tying concrete box beams and steel bars, applied in the field of construction, can solve the problems of weakening the advantages of segment beam construction, affecting the appearance, reducing construction efficiency, etc., and achieving the effects of reducing construction errors, reducing the out-of-position of steel bars, and increasing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

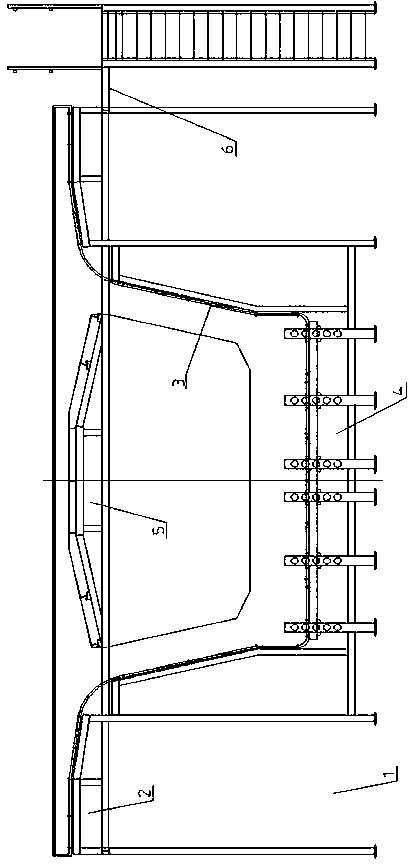

[0028] see figure 1 , figure 1 It is a front view of the overall structure of an embodiment of the segmental prefabricated variable-section concrete box girder steel bar binding tire frame of the present invention. The segmental prefabricated variable-section concrete box girder steel bar binding frame provided by the present invention is mainly used for binding steel bars to the prefabricated segmental concrete box girder. The segmental prefabricated variable cross-section concrete box girder reinforcement binding frame mainly includes the main body support 1, the wing plate fixing support 2, the web fixing support 3, the bottom plate fixing support 4, the roof internal fixing support 5 and the construction platform 6.

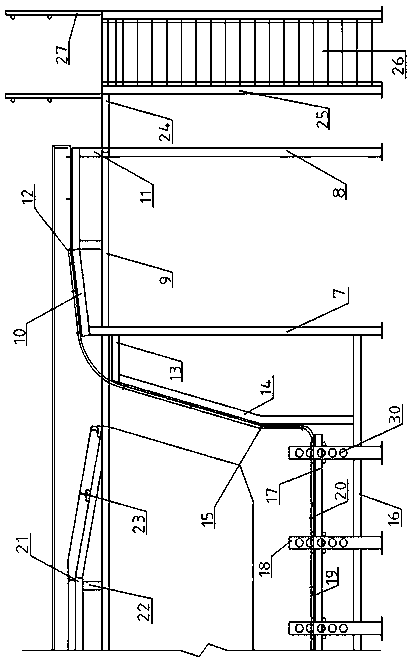

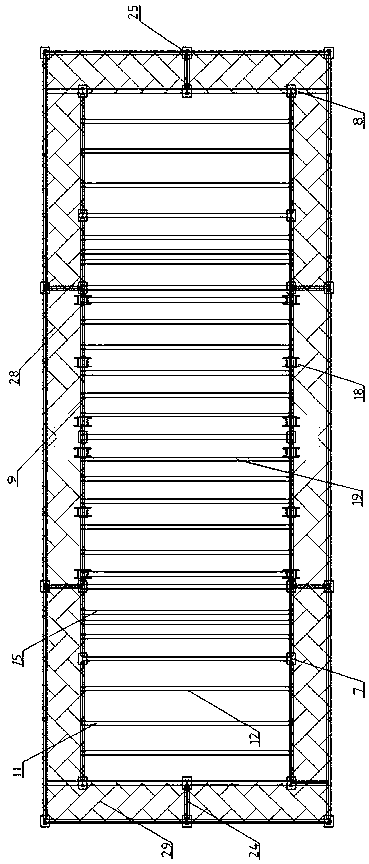

[0029] see figure 2 and image 3 , figure 2 and image 3 Structural views from different angles of view for the components of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com