A reinforced SMA composite material with low warpage and high dimensional stability for automobile structural parts and preparation method thereof

A dimensional stability and composite material technology, applied in the field of polymer materials, can solve the problems of affecting the size of the material, the adverse effect of glass fiber dispersion, and the low degree of isotropy of the material, so as to avoid low crystallization efficiency and crystallization tendency Low, low coefficient of linear expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

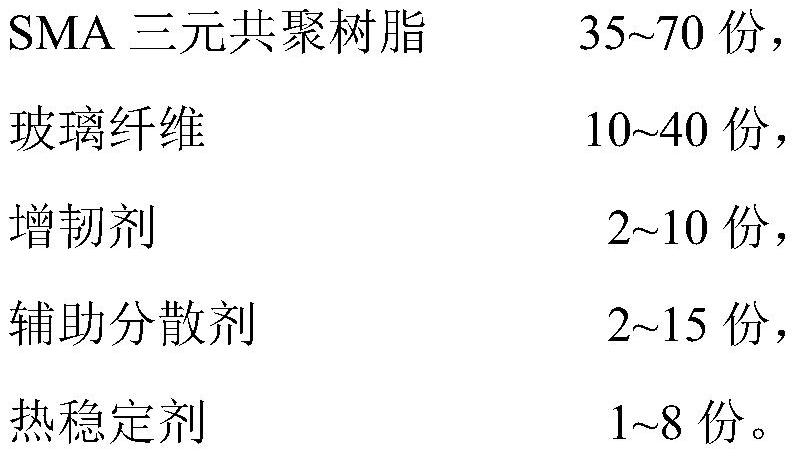

Method used

Image

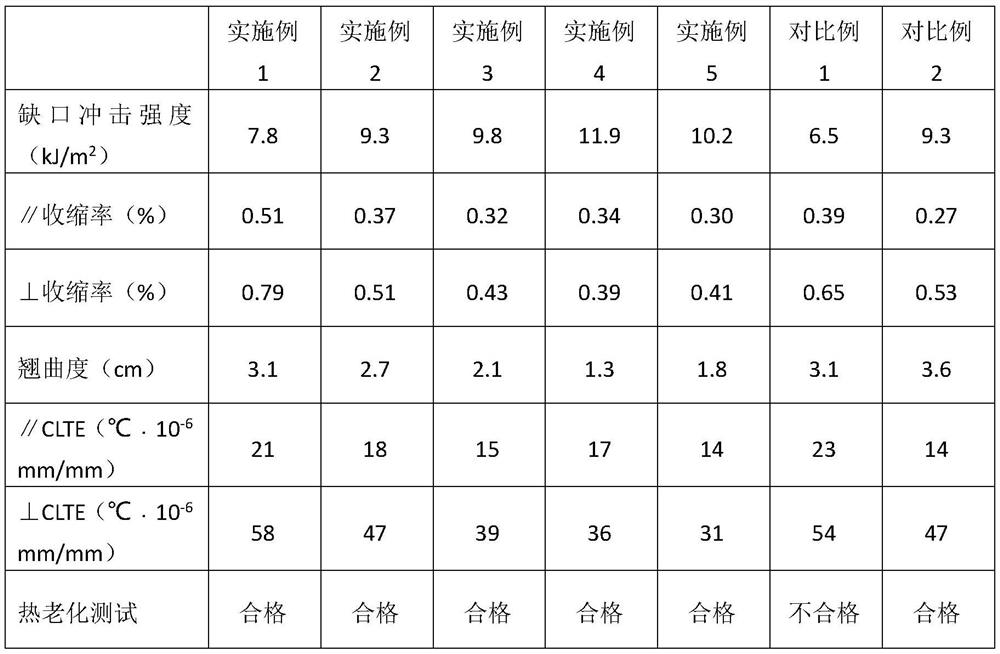

Examples

Embodiment 1

[0039] Weigh the SMA ternary resin, toughening agent, auxiliary dispersant, and heat stabilizer according to the data of Example 1 shown in Table 1, and mix them uniformly to obtain mixed raw materials.

[0040] The dried mixed raw materials are placed in the main feeding bin of a twin-screw extruder with close meshing and co-rotation, and are fed into the barrel of the extruder through the feeding screw, and the glass fiber is fed from the side feeding port. It is added to the extruder, the diameter of the extruder screw is 36mm, the length-diameter ratio L / D is 44, and the temperature of each zone of the main barrel from the feeding port to the head outlet is set as: 100°C, 190°C, 200°C, 215°C, 220°C, 220°C, 220°C, the main engine speed is 200 rpm, and the product is obtained after melt extrusion, cooling, granulation, drying and other processes.

[0041]Table 1 Formulation of reinforced SMA composites with low warpage and high dimensional stability for automotive structural...

Embodiment 2

[0044] Weigh SMA ternary resin, toughening agent, auxiliary dispersant, and heat stabilizer according to the data of Example 2 shown in Table 1, and mix them uniformly to obtain mixed raw materials.

[0045] The dried mixed raw materials are placed in the main feeding bin of a twin-screw extruder with close meshing and co-rotation, and are fed into the barrel of the extruder through the feeding screw, and the glass fiber is fed from the side feeding port. It is added to the extruder, the diameter of the extruder screw is 36mm, the length-diameter ratio L / D is 44, and the temperature of each zone of the main barrel from the feeding port to the head outlet is set as: 100°C, 190°C, 200°C, 215°C, 220°C, 220°C, 220°C, the main engine speed is 200 rpm, and the product is obtained after melt extrusion, cooling, granulation, drying and other processes.

Embodiment 3

[0047] Weigh SMA ternary resin, toughening agent, auxiliary dispersant, and heat stabilizer according to the data of Example 3 shown in Table 1, and mix them uniformly to obtain mixed raw materials.

[0048] The dried mixed raw materials are placed in the main feeding bin of a twin-screw extruder with close meshing and co-rotation, and are fed into the barrel of the extruder through the feeding screw, and the glass fiber is fed from the side feeding port. It is added to the extruder, the diameter of the extruder screw is 36mm, the length-diameter ratio L / D is 44, and the temperature of each zone of the main barrel from the feeding port to the head outlet is set as: 100°C, 190°C, 200°C, 215°C, 220°C, 220°C, 220°C, the main engine speed is 200 rpm, and the product is obtained after melt extrusion, cooling, granulation, drying and other processes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com