Road repairing device and repairing method

A road repair and width technology, applied in road repair, road, road and other directions, can solve the problem of asphalt that cannot be adjusted to fill, and achieve the effect of filling evenly and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

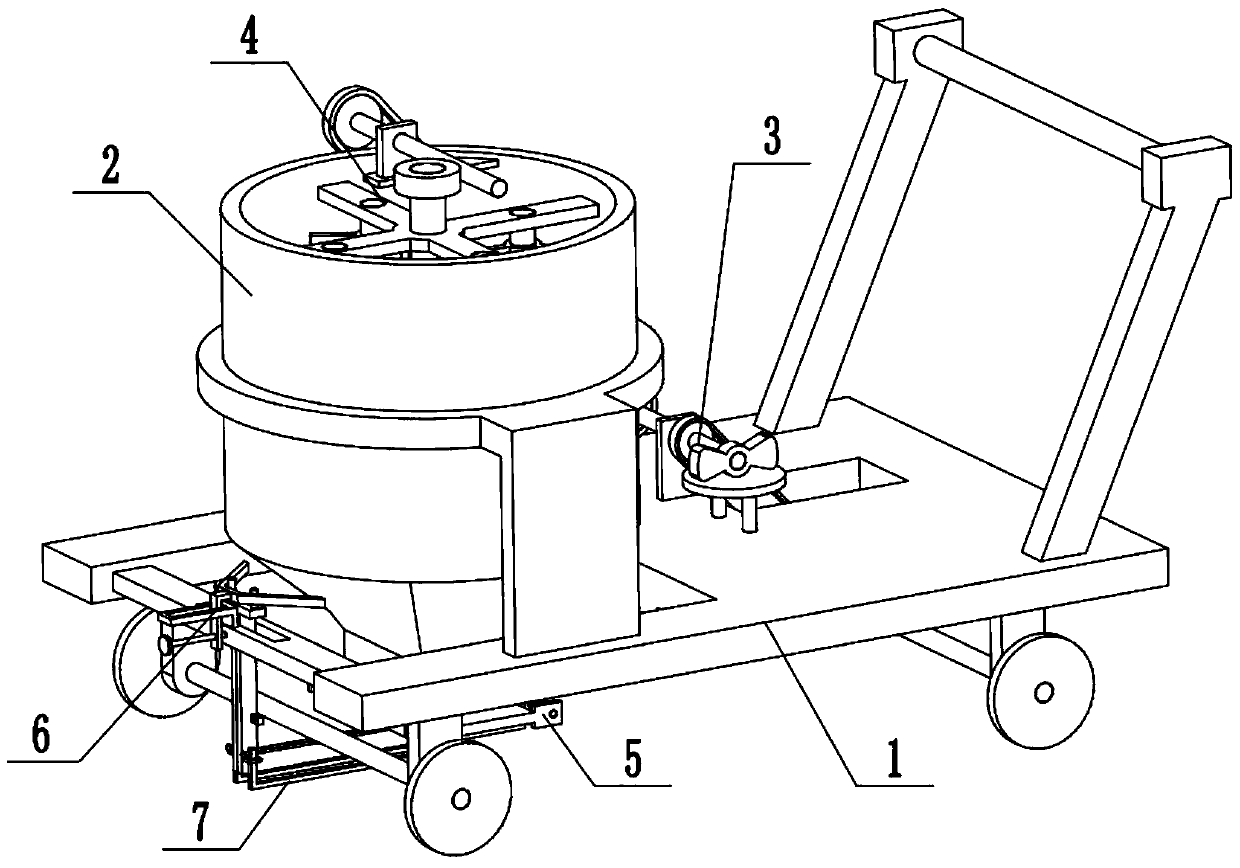

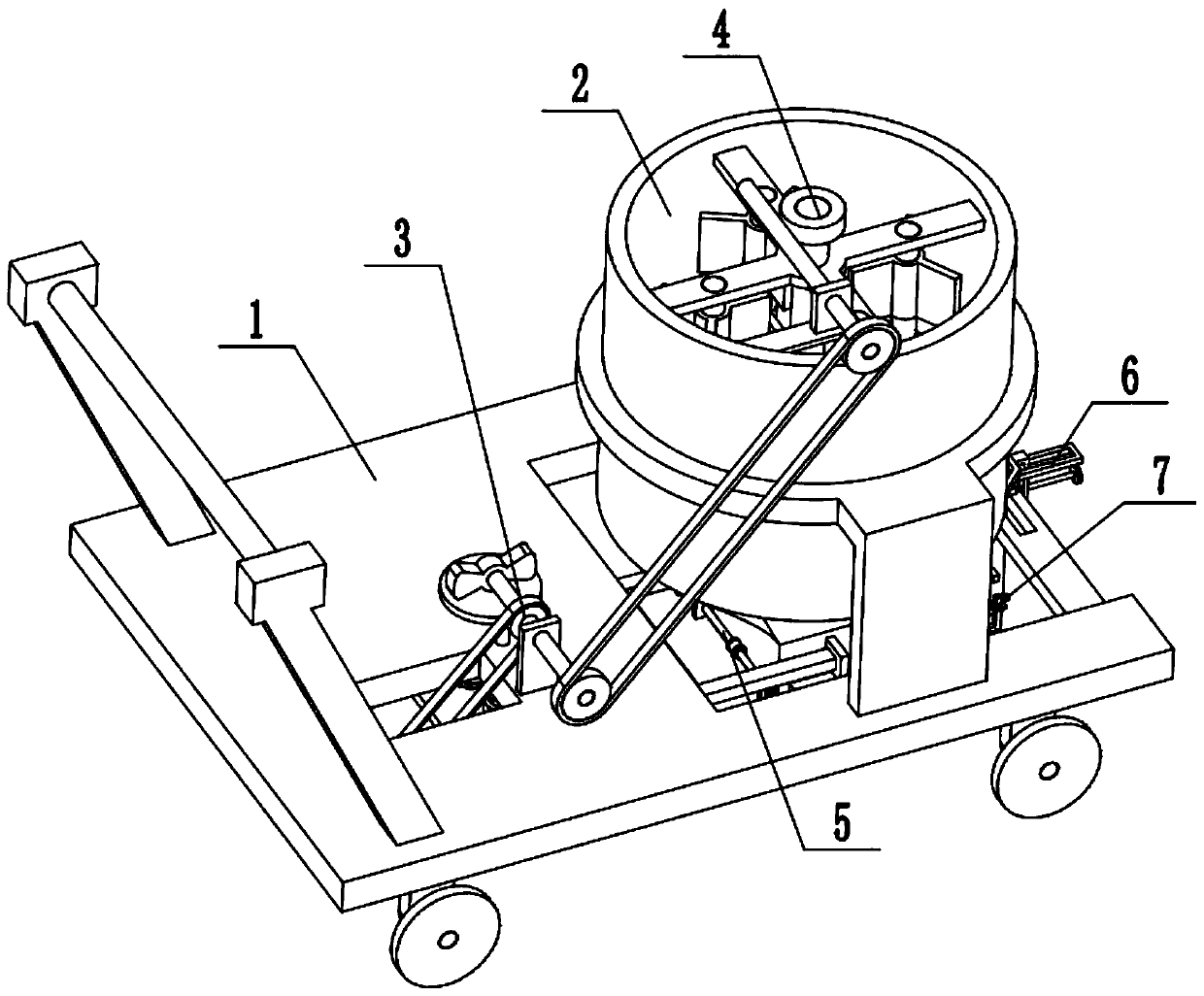

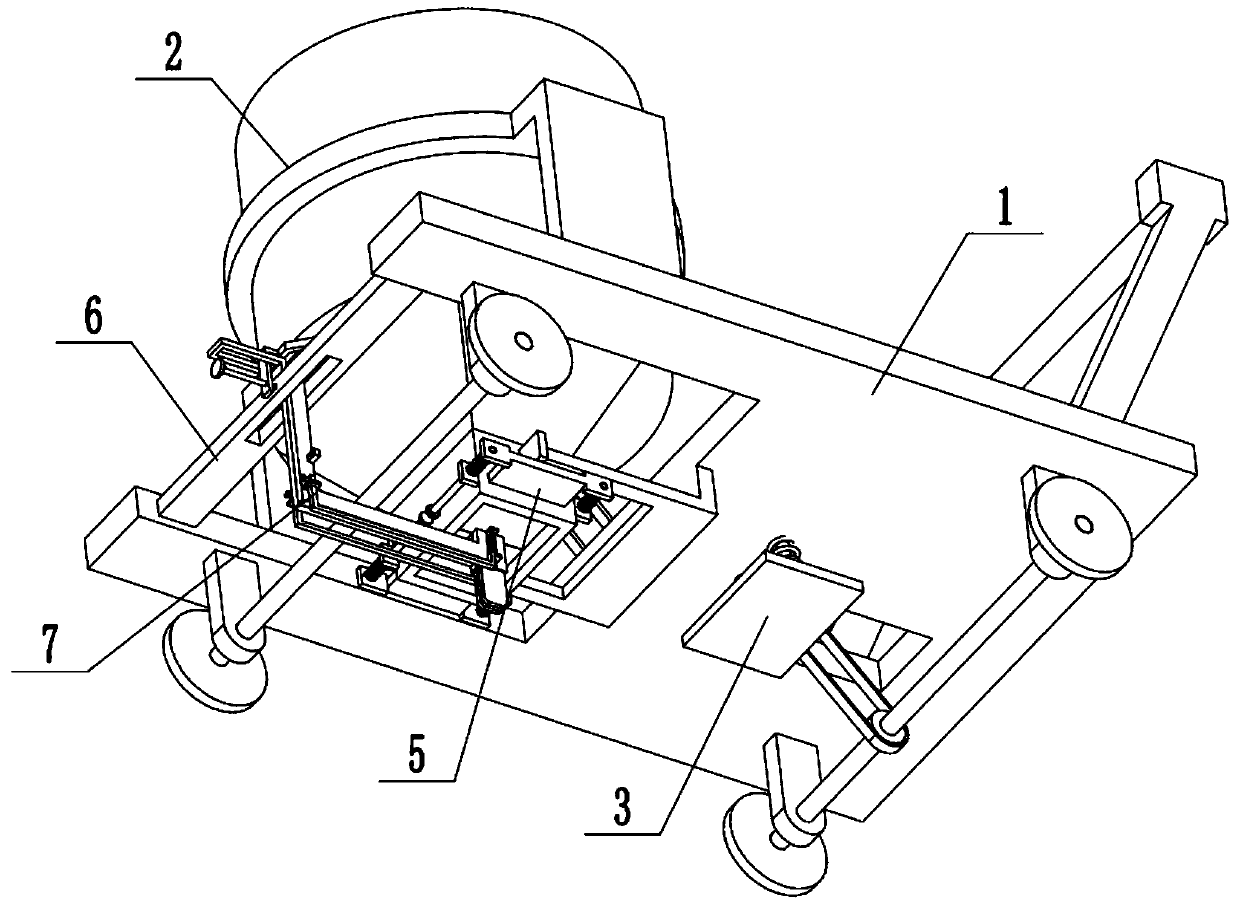

[0037] Combine below Figure 1-11 Describe this embodiment, a road repair device and repair method, including a mobile cart 1, an asphalt storage cylinder 2, a flattening mechanism 3, a stirring mechanism 4, a width-adaptive floor frame 5, a width locking mechanism 6 and a width-adaptive plate Component 7, the asphalt storage cylinder 2 is fixedly connected to the mobile cart 1, the flattening mechanism 3 is arranged on the right end of the asphalt storage cylinder 2, the flattening mechanism 3 is connected to the mobile cart 1 by transmission, and the mixing mechanism 4 is arranged on the asphalt On the storage cylinder 2, the stirring mechanism 4 is connected with the flattening mechanism 3 in transmission, and two width-adaptive floor frames 5 are provided. Fixedly connected to the left end of the mobile cart 1, the left ends of the two width-adaptive floor frames 5 are slidingly fitted and connected to the width locking mechanism 6, and two width-adaptive board assemblies ...

specific Embodiment approach 2

[0039] Combine below Figure 1-11 To illustrate this embodiment, the mobile trolley 1 includes a chassis plate 1-1, a trolley frame 1-2, a belt passing groove 1-3, a cylinder support frame 1-4, a roller shaft 1-5, and a shaft frame 1 -6, roller 1-7 and driving pulley 1-8; hand push frame 1-2 is fixedly connected to the right end of chassis plate 1-1, and belt is arranged on the chassis plate 1-1 through groove 1-3, and tube The support frame 1-4 is fixedly connected to the bottom surface of the chassis plate 1-1, and the two roller shafts 1-5 are respectively rotatably connected to the two shaft frames 1-6, and the two roller shafts 1-5 respectively pass through the two shaft frames 1-6 is fixedly connected to the left and right ends of the chassis plate 1-1, the two ends of the two roller shafts 1-5 are respectively fixedly connected to a roller 1-7, and the driving pulley 1-8 is fixedly connected to the right roller shaft 1-5, driving pulley 1-8 is connected with flattening...

specific Embodiment approach 3

[0041] Combine below Figure 1-11 To illustrate this embodiment, the asphalt storage cylinder 2 is fixedly connected to the cylinder frame 2-1, and the lower end of the asphalt storage cylinder 2 is symmetrically provided with two material baffle slide grooves 2-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com