Construction method for large-size air duct in steel structure net rack

A construction method and steel structure technology, applied to building components, vertical pipes, building structures, etc., can solve the problems of high construction cost, difficulty in ensuring safety, slow construction progress, etc., and achieve shortened construction period, good economic benefits and social benefits. Benefits, cost-reducing effects of measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

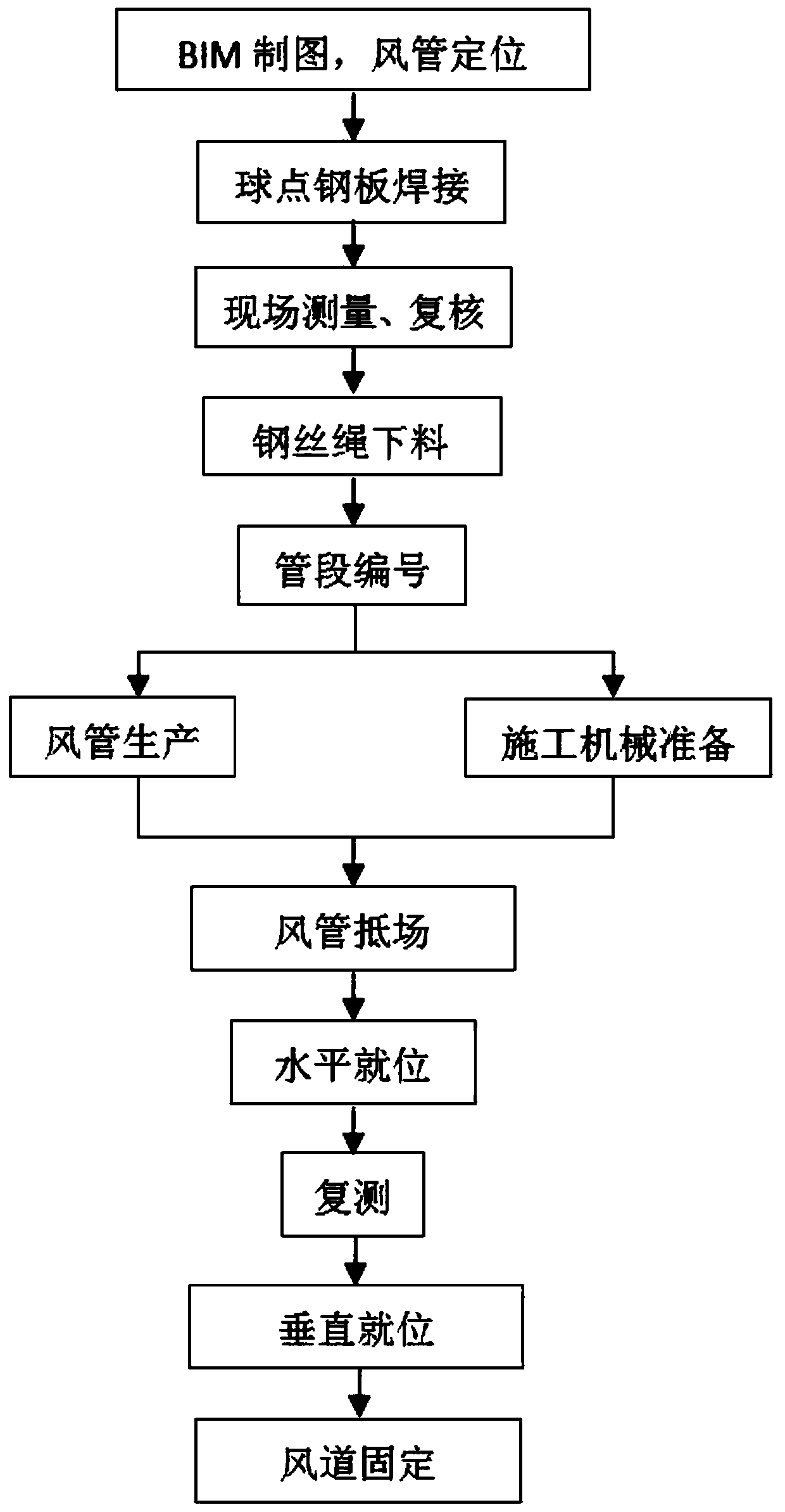

[0059] A construction method for a large-scale air duct in a steel structure grid, the method uses BIM arrangement to locate the air duct to be constructed;

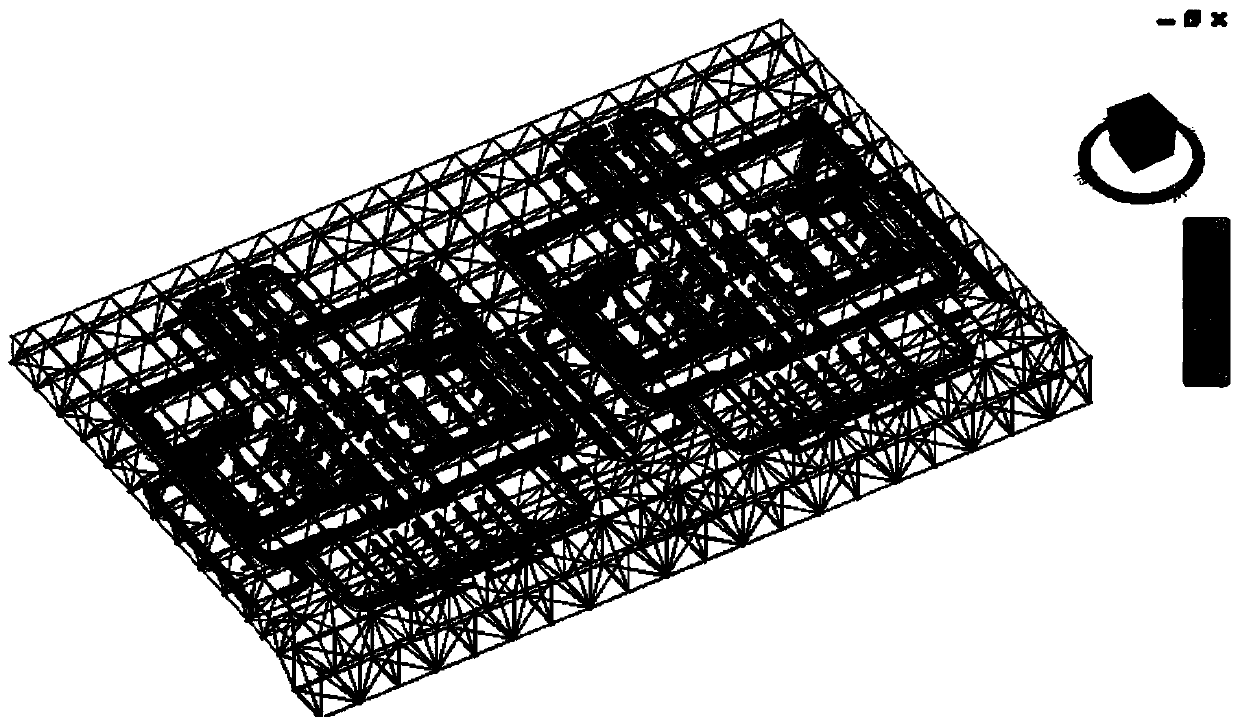

[0060] Through BIM typesetting, select the ball point of the steel structure grid, and weld and fix the steel plate on the ball point;

[0061] Review the upper and lower string balls of the steel structure, measure the actual net size, and optimize the BIM drawings;

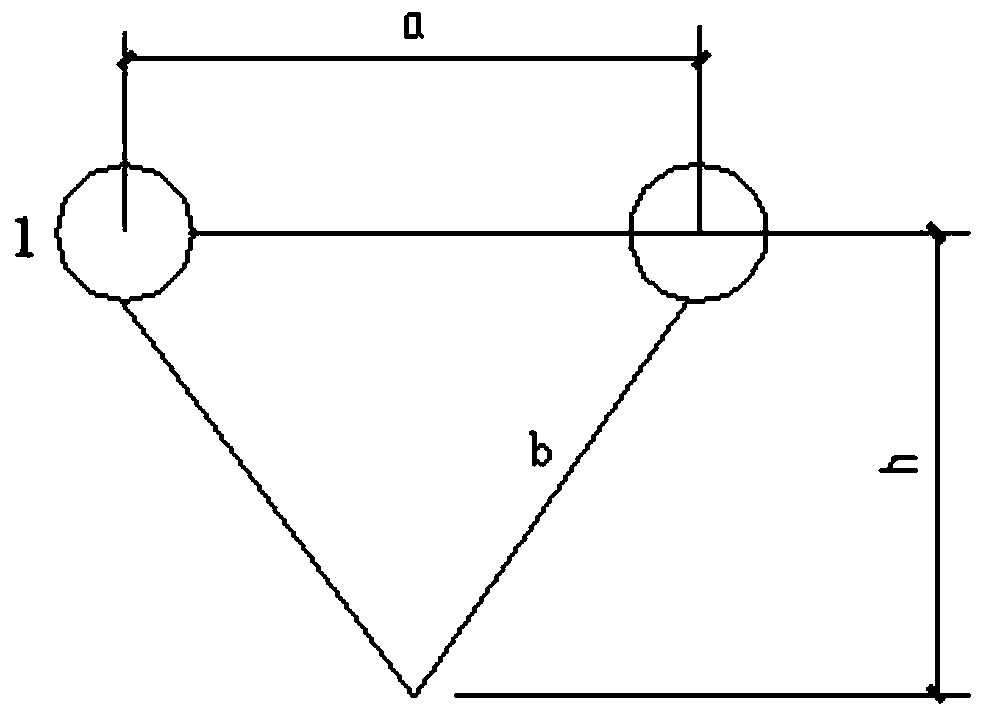

[0062] Calculate the length of the steel wire rope at each point according to the optimized BIM drawing, and carry out the blanking of the steel wire rope;

[0063] Split and number the entire air duct system according to the optimized BIM drawing, and carry out on-site processing of the air duct;

[0064] Install the air ducts according to the optimized BIM drawings.

[0065] The BIM software is used to accurately positio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap