Fire insulation door

A technology for insulating doors and door panels, applied to fire doors, door leaves, windows/doors, etc., can solve the problems of general fire performance, short fire protection time, suffocation, etc., to prevent direct contact with the door body, increase fire protection time, and increase distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

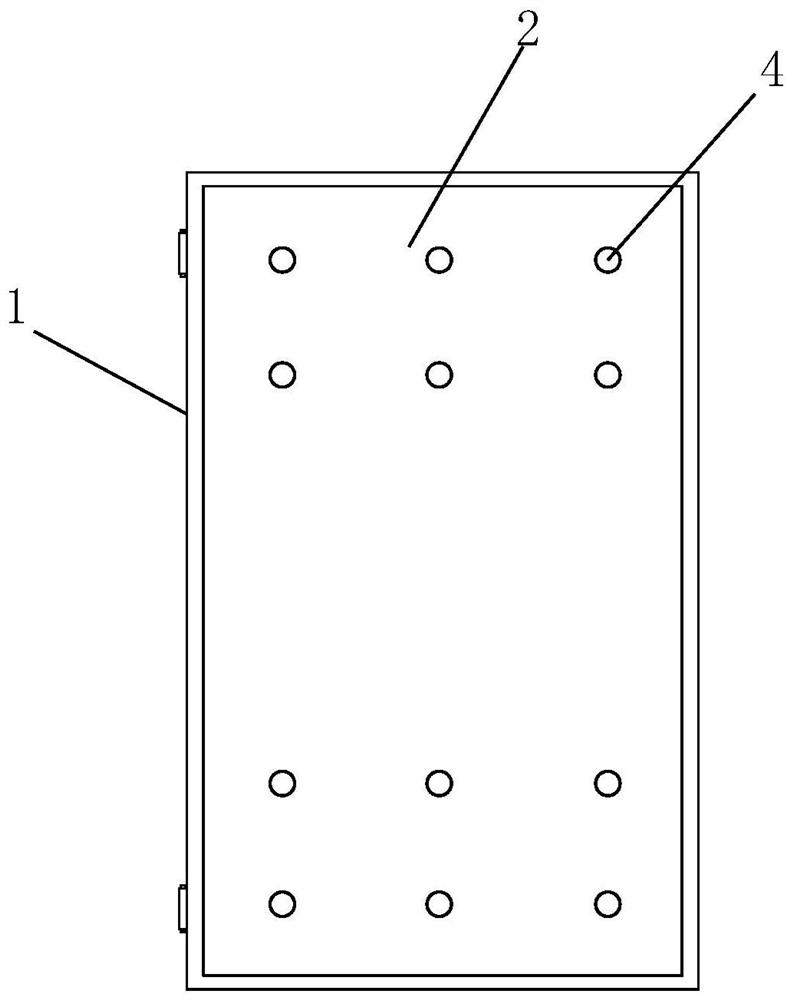

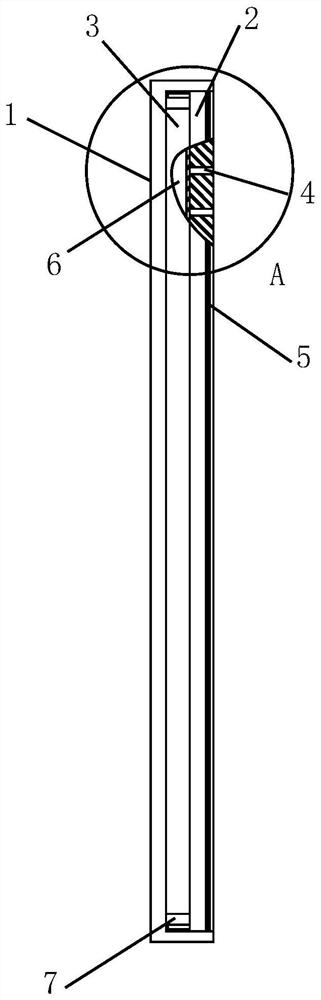

[0019] Such as figure 1 with figure 2 As shown, the fireproof and insulating door includes a fireproof door body 1, a cavity 7 is provided on one side of the fireproof door body 1, an expansion body 3 is bonded to the bottom surface of the cavity 7, and the outer end of the expansion body 3 is loaded into a floating door panel 2. The inner end of the floating door panel 2 is in contact with one side of the expansion body 3, and the outer surface of the floating door panel 2 surrounds the floating door panel 2 with a circle of card slots, and a water storage ring 5 is placed in the card slot;

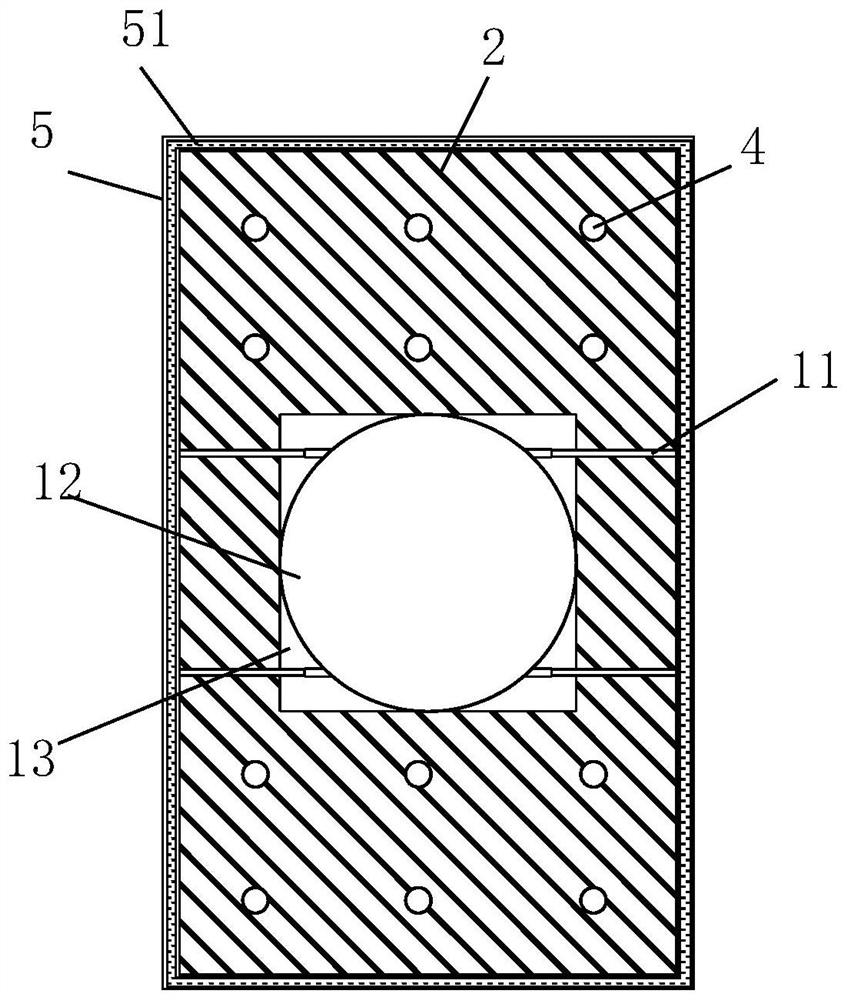

[0020] Such as image 3 As shown, a hollow cavity 13 is provided inside the floating door panel 2, and a water storage bag 12 is loaded into the hollow cavity 13, and the water storage bag 12 is filled with water and the water storage bag 12 is expanded. Above aqueduct 11, the other end of more than one aqueduct 11 is all connected with the inlet and outlet water interface of water st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com