Shock absorber with locking type vehicle-used hydraulic jacking rod

A technology of hydraulic ejector rod and shock absorber, which is applied in the direction of shock absorber, liquid shock absorber, spring/shock absorber, etc., and can solve the problem of accelerated seal ring wear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

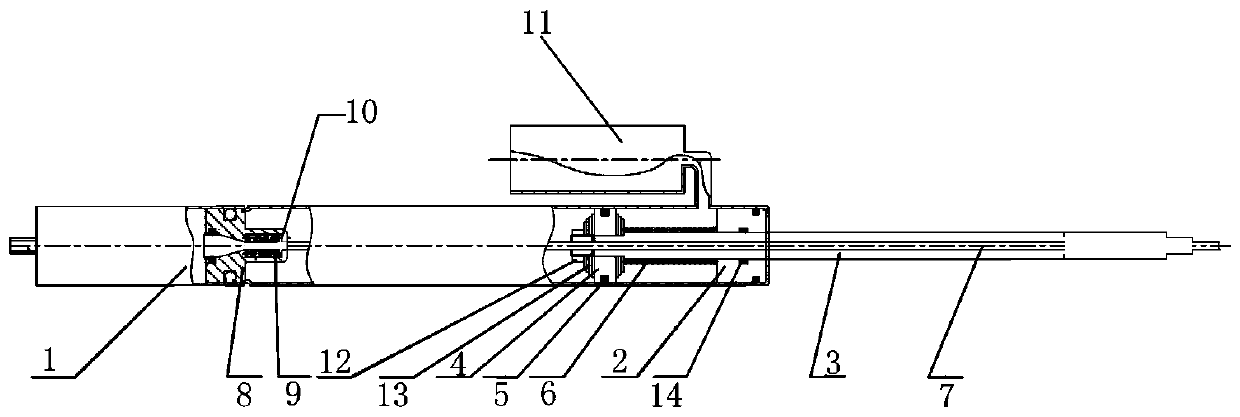

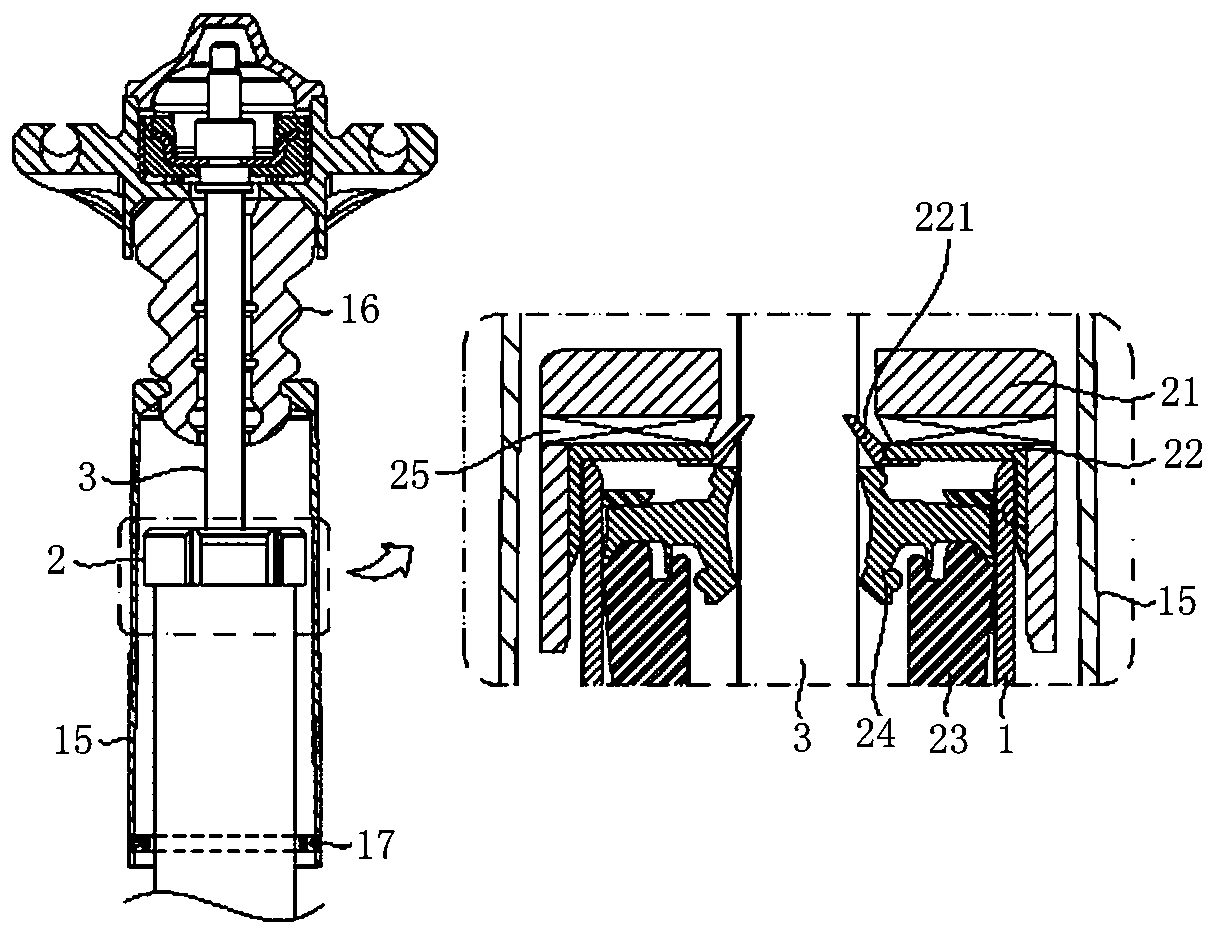

[0013] The shock absorber with locking type vehicle hydraulic jack in the present invention will be further described with reference to the accompanying drawings.

[0014] As shown in the drawings, this embodiment is a shock absorber with a lock-type vehicle hydraulic jack, including a cylindrical working cylinder 1, the inside of the working cylinder is hollow to form a cavity, and the rear of the working cylinder end seal, the front end cover of the working cylinder is provided with a guide 2, and the cavity is sealed by the guide, and a through hole is formed in the center of the guide, and the through hole communicates with the cavity. A push rod 3 is plugged into the through hole, the front end of the push rod extends outside the working cylinder, and the rear end of the push rod is inserted into the cavity, and the whole push rod can be subjected to an external impact force. After the action, it is reciprocatingly fed along the axial direction of the working cylinder. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com