A continuous jacking device for steel pipes

A technology of jacking and steel pipe, applied in the direction of pipeline laying and maintenance, pipe/pipe joints/pipe fittings, machinery and equipment, etc., can solve the problems of continuous jacking of steel pipes and low jacking efficiency of steel pipes, and achieve efficient jacking operation. , the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

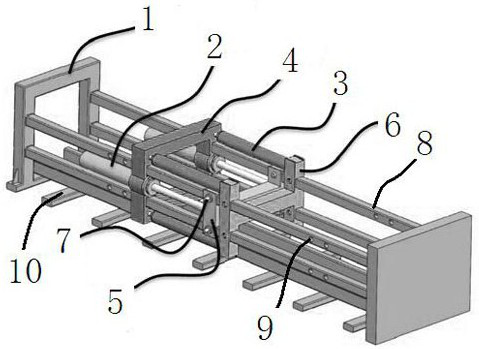

[0012] A continuous jacking device for steel pipes, comprising a jacking frame 1 and an oil cylinder, the oil cylinders are a large oil cylinder 2 and a small oil cylinder 3, a jacking frame 4 is arranged on the jacking frame 1, and the jacking frame 4 is arranged on the jacking frame 1. The entry frame 4 is divided into a jacking front frame and a jacking rear frame, and an oil cylinder accommodation chamber is arranged between the jacking front frame and the jacking rear frame, and a large oil cylinder coupling frame 5 is arranged on the jacking frame 1 , the large oil cylinder coupling frame 5 is provided with a large oil cylinder 2, the small oil cylinder coupling frame 6 is arranged on the described jacking rear frame, and the small oil cylinder 3 is arranged on the described small oil cylinder coupling frame 6, so A plug-in component 7 is arranged between the large oil cylinder coupling frame 5 and the jacking frame 1, and the plug-in component 7 passes through the large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com