Optical fiber displacement sensor and measuring method thereof

A technology of displacement sensor and optical fiber sensor, which is applied in the field of sensors, can solve the problems of large size and achieve the effects of small size, cost saving and long signal transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

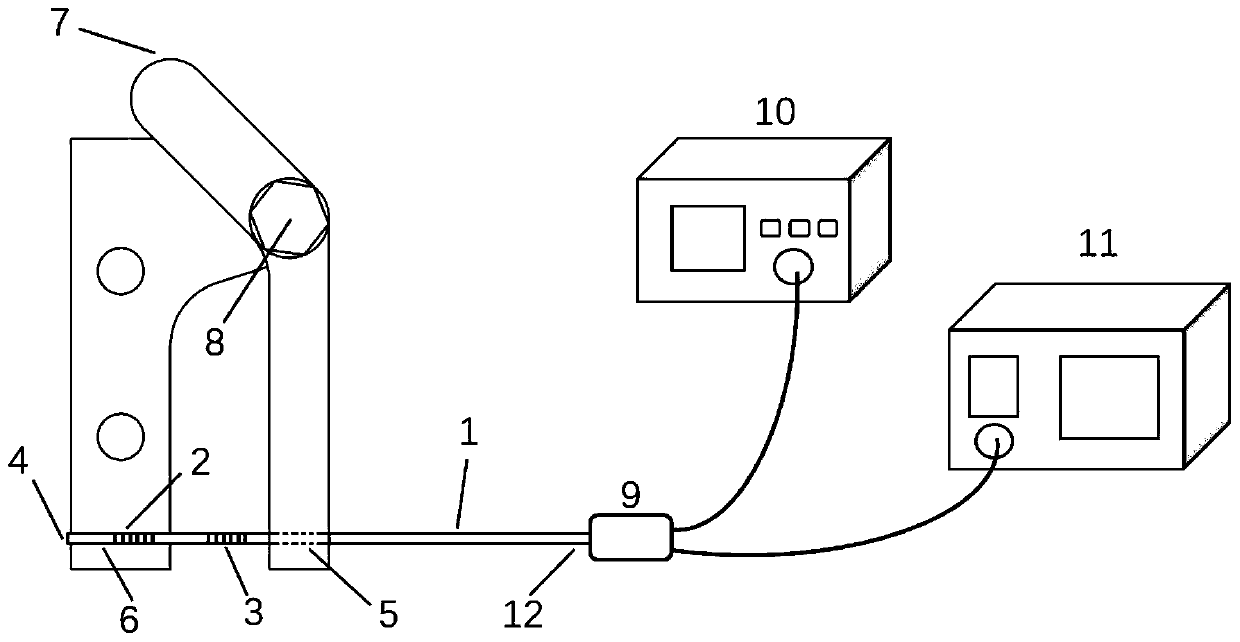

[0042] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

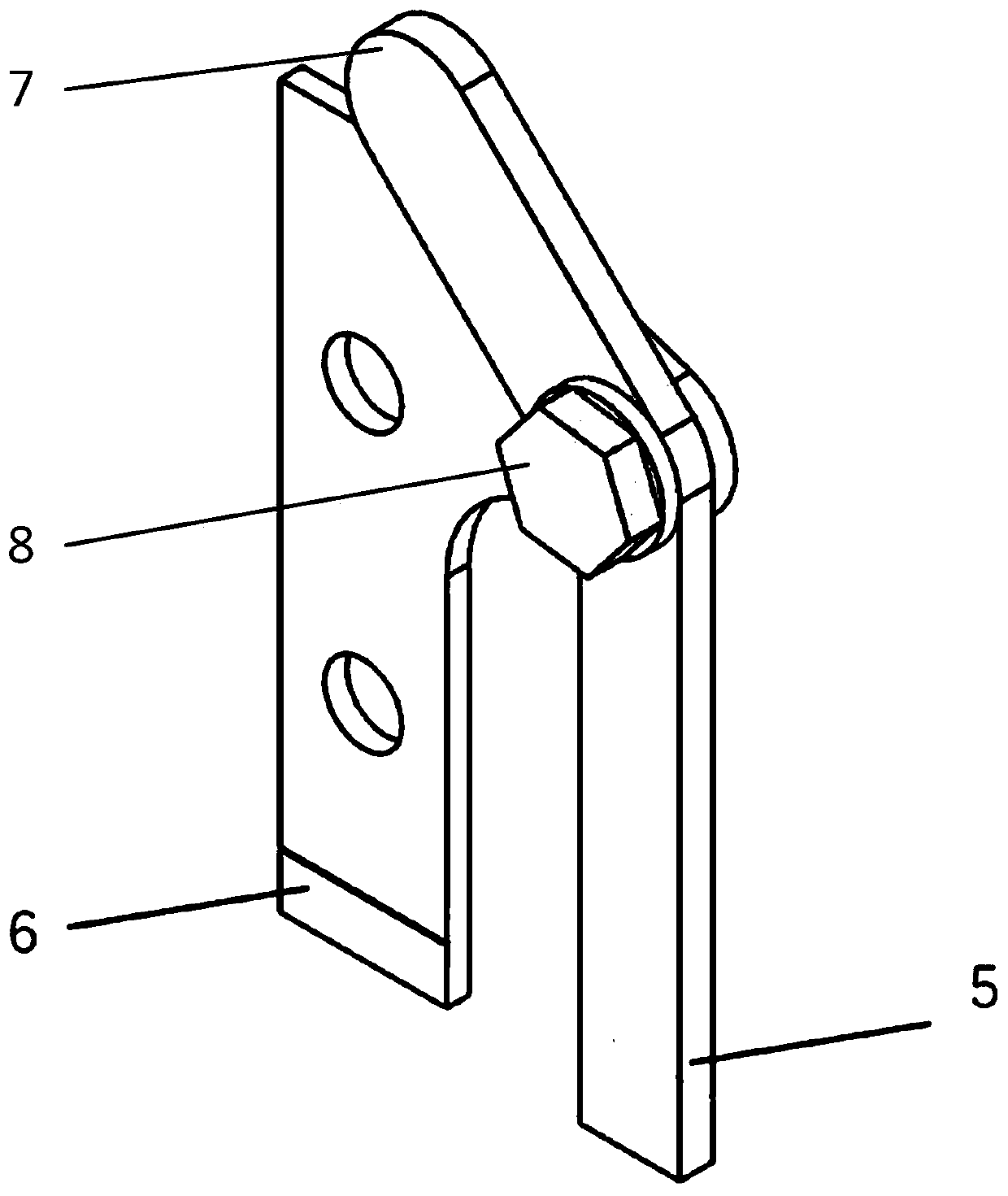

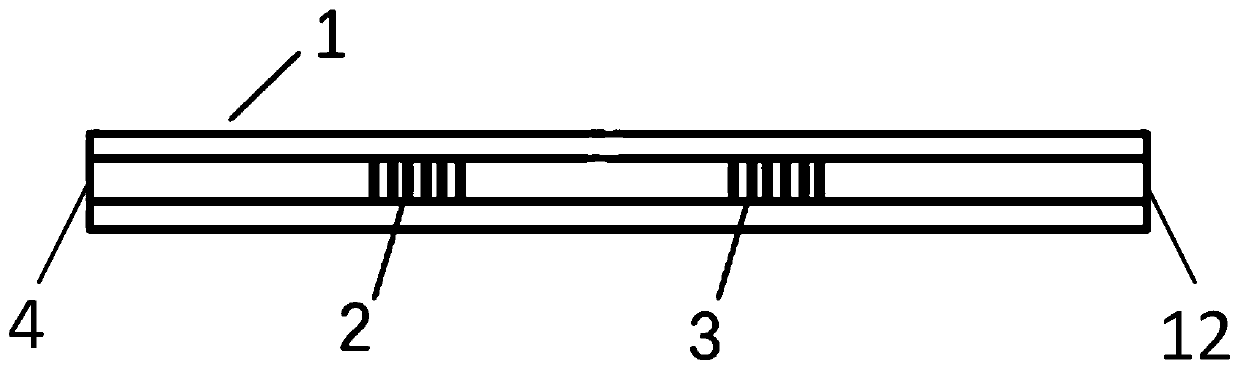

[0043] The invention provides an optical fiber displacement sensor, such as figure 1 As shown, it includes a substrate and an optical fiber sensor; the substrate includes a fixing plate, a turning plate and a connector 8, the fixing plate has three through holes and an optical fiber groove-5, and the turning plate is divided into an upper corner by a through hole at a corner The lower turning plate is parallel to the fixed plate, and the direction of the corner towards the fixed plate is an obtuse angle, and the angle of the obtuse angle is greater than or equal to 110°. The connecting piece 8 connects the The fixing plate is connected with the turning plate, the other tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com