4G technology based petrochemical safety sensing equipment monitoring device and method

A technology of sensing equipment and monitoring devices, applied in signal transmission systems, instruments, etc., can solve problems such as personal injury, economic loss, parameter transmission, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

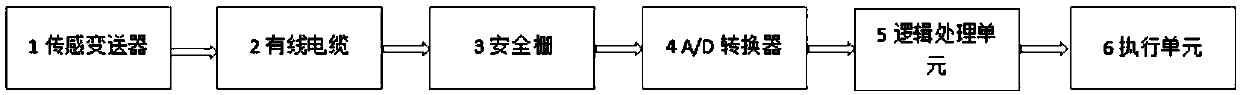

[0025] The traditional petrochemical safety sensor equipment data monitoring and transmission structure such as figure 1 Shown.

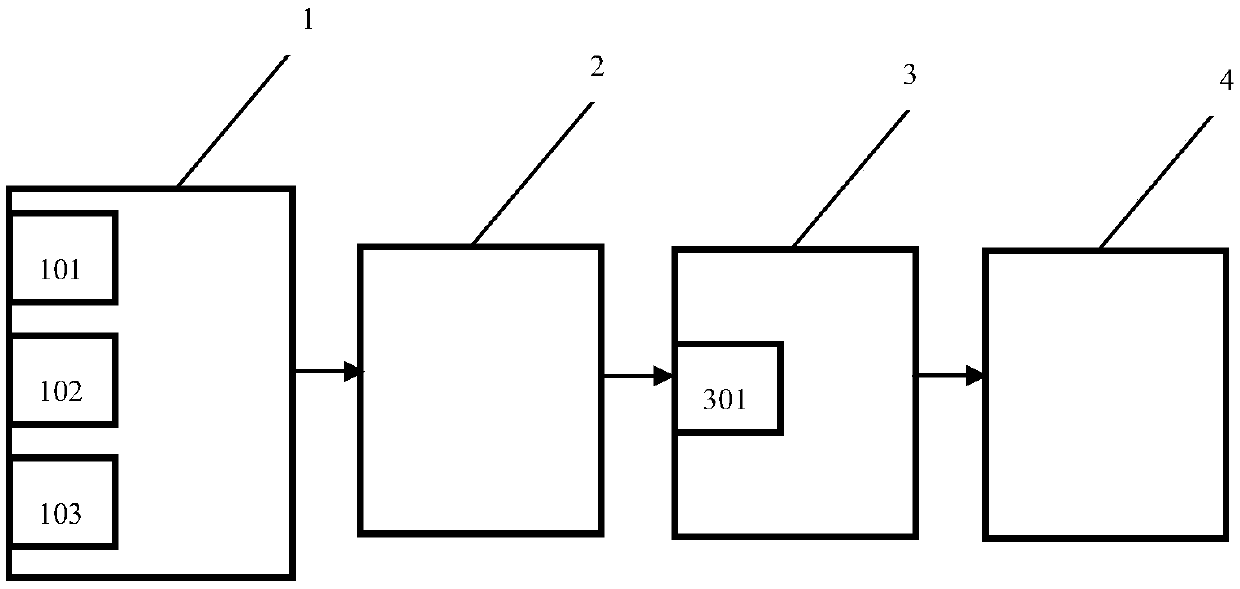

[0026] A monitoring device for petrochemical safety sensing equipment based on 4G technology, such as figure 2 As shown, it includes a sensing device 1, a base station 2, a logic processing unit 3, and an execution unit 4;

[0027] The sensing device 1 includes a sensing unit 101, an A / D conversion unit 102, and a first 4G communication module 103; the sensing unit 101, A / D conversion unit 102, and the first 4G communication module 103 are connected in sequence through lines ;

[0028] The logic processing unit 3 includes a second 4G communication module 301;

[0029] The first 4G communication module 103, the base station 2 and the second 4G communication module 301 perform data transmission through wireless;

[0030] The second 4G communication module 301 and the execution unit 4 are connected by wires.

[0031] The sensing equipment 1 includes temperatur...

Embodiment 2

[0033] On the basis of the foregoing embodiments, the present invention also mentions a method for monitoring petrochemical safety sensor equipment based on 4G technology, which specifically includes the following steps:

[0034] Step 1: Determine the status of existing petrochemical sensing equipment

[0035] Respectively determine whether the existing petrochemical safety sensing equipment includes a sensing unit, A / D conversion equipment, etc.; if the sensing unit uses wired data transmission, it should be replaced with a corresponding transmission that includes an A / D converter and 4G module. Sensing equipment; here replace the corresponding temperature and pressure sensors;

[0036] Step 2: Determine the data transmission path

[0037] Determine the data communication form and path between the sensor unit and the logic processing unit, conduct the corresponding data validity test, and put it into use after confirming the data exchange;

[0038] Step 3: When monitoring the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com